Method for preparing polyaluminum chloride and coproducing polysilicate ferric aluminum chloride by using waste catalyst

A technology of polysilicon ferric aluminum chloride and waste catalysts, which is applied in the fields of aluminum chloride, chemical instruments and methods, aluminum halide, etc., can solve problems such as secondary pollution of water quality, and achieve the effect of increasing production income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

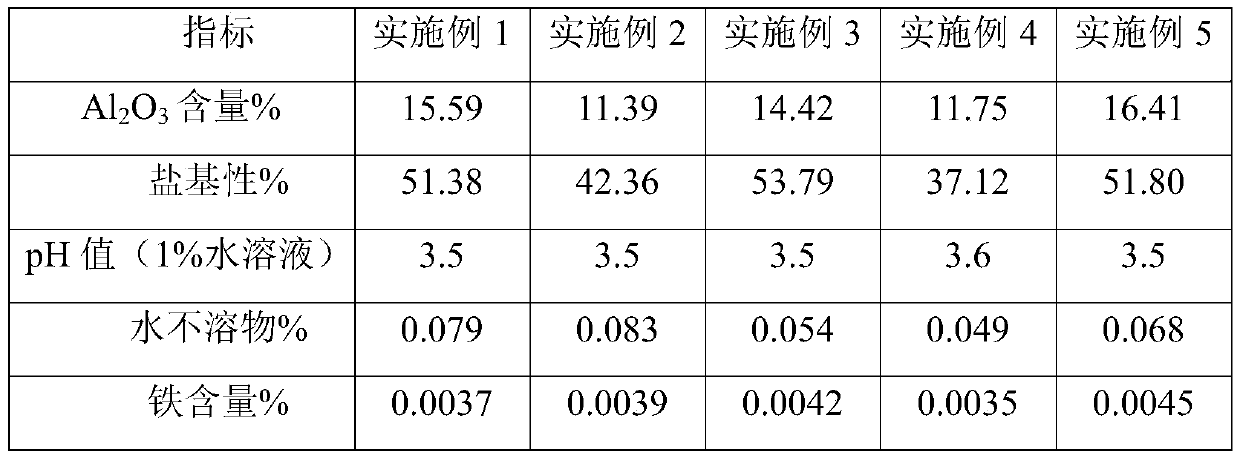

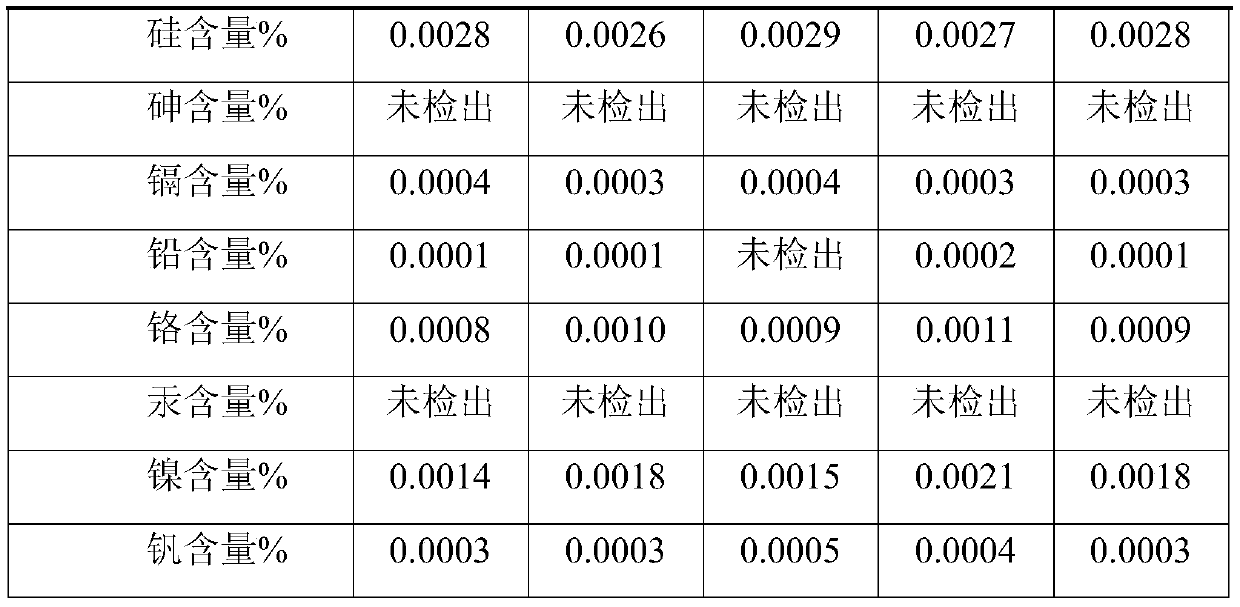

Examples

Embodiment 1

[0065](1) Mix 480ml of 15% sodium hydroxide solution and 100g of FCC waste catalyst in a stainless steel autoclave, set the stirring speed at 800rpm, heat up with electric heating, maintain the reaction temperature at 125°C and the pressure at 0.26MPa, and perform alkali leaching reaction for 4h . After the reaction is completed, it is transferred to a titanium rod filter while it is hot, and forced to filter to obtain an aluminosilicate solution.

[0066] (2) Transfer the aluminosilicate solution to a three-necked flask, install a condenser, connect a water circulation vacuum pump, and concentrate the aluminosilicate in a vacuum; the concentration temperature is 75°C, the vacuum degree is -0.08MPa, and the concentration end point is an alkali concentration of 220g / L (in Na 2 O meter).

[0067] (3) At an initial temperature of 80°C, add 64g of aluminum hydroxide seeds and 2.24g of crystallization aid sodium stearate to the concentrated aluminosilicate solution to promote the...

Embodiment 2

[0072] (1) Mix 345ml of 20% sodium hydroxide solution and 100g of spent FCC catalyst in a stainless steel autoclave, set the stirring speed at 1000rpm, heat up with electric heating, maintain the reaction temperature at 100°C and the pressure at 0.15MPa, and carry out alkaline leaching reaction for 5h . After the reaction is completed, it is transferred to a titanium rod filter while it is hot, and forced to filter to obtain an aluminosilicate solution.

[0073] (2) Transfer the aluminosilicate solution to a three-necked flask, install a condenser, connect a water circulation vacuum pump, and concentrate the aluminosilicate in a vacuum; the concentration temperature is 80°C, the vacuum degree is -0.08MPa, and the concentration end point is an alkali concentration of 240g / L (in Na 2 O meter).

[0074] (3) At an initial temperature of 90°C, throw 31.6g of aluminum hydroxide seeds and 1.58g of crystallization aid sodium stearate into the concentrated aluminosilicate solution to...

Embodiment 3

[0079] (1) Mix 760ml of 10% sodium hydroxide solution and 100g of spent FCC catalyst in a stainless steel autoclave, set the stirring speed at 600rpm, heat up with electric heating, maintain the reaction temperature at 135°C and the pressure at 0.35MPa, and perform alkali leaching reaction for 3h . After the reaction is completed, it is transferred to a titanium rod filter while it is hot, and forced to filter to obtain an aluminosilicate solution.

[0080] (2) Transfer the aluminosilicate solution to a three-necked flask, install a condenser, connect a water circulation vacuum pump, and concentrate the aluminosilicate in a vacuum; the concentration temperature is 70°C, the vacuum degree is -0.08MPa, and the concentration end point is an alkali concentration of 180g / L (in Na 2 O meter).

[0081] (3) At an initial temperature of 83°C, 93.5g of aluminum hydroxide seeds and 1.87g of crystallization aid sodium stearate were thrown into the concentrated aluminosilicate solution t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com