Two-component exterior wall coating and preparation method thereof

A two-component technology for exterior wall coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of slow drying speed, poor paint film elasticity and wear resistance, and difficulty in thick coating. Fast speed, good aging resistance, fast hardness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

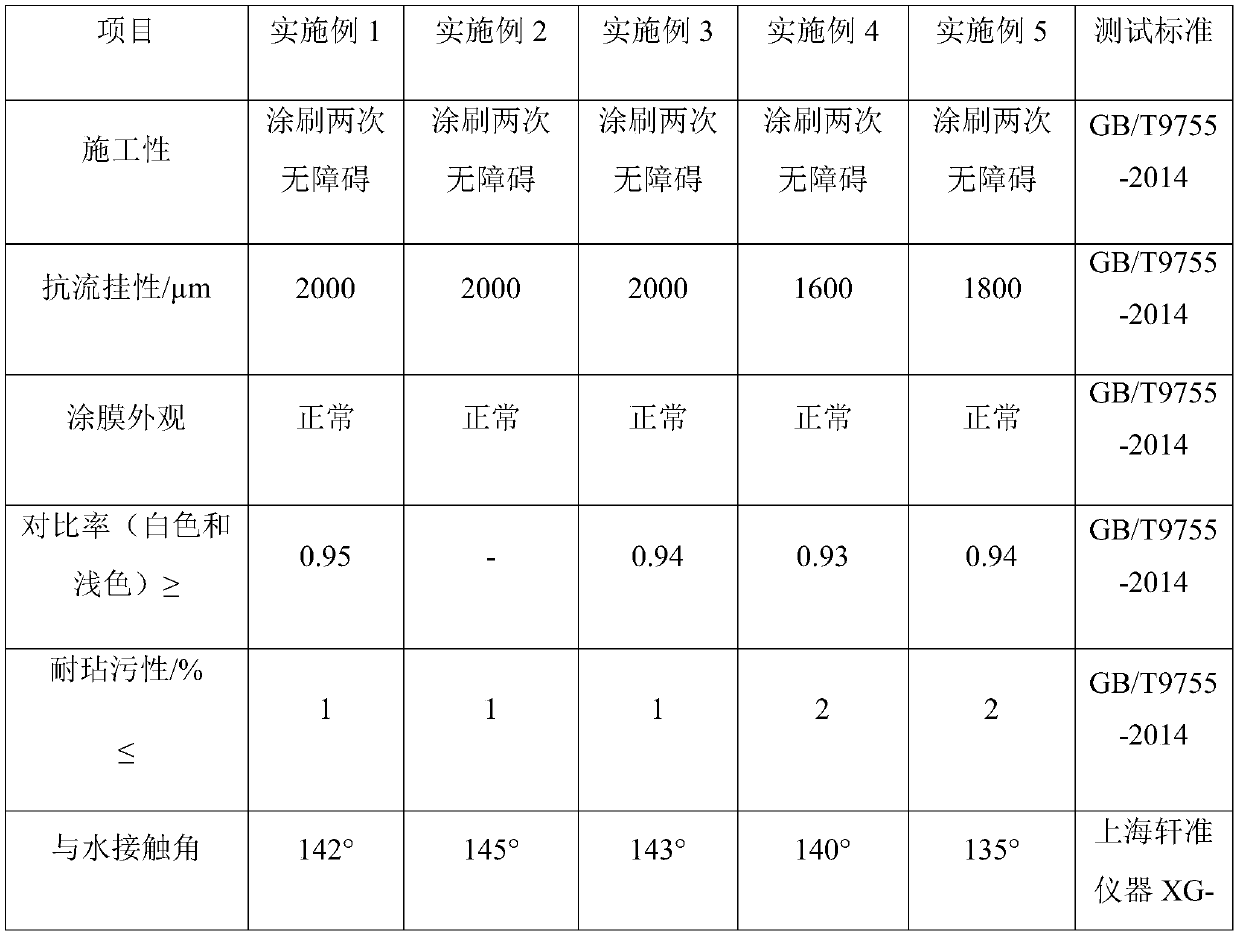

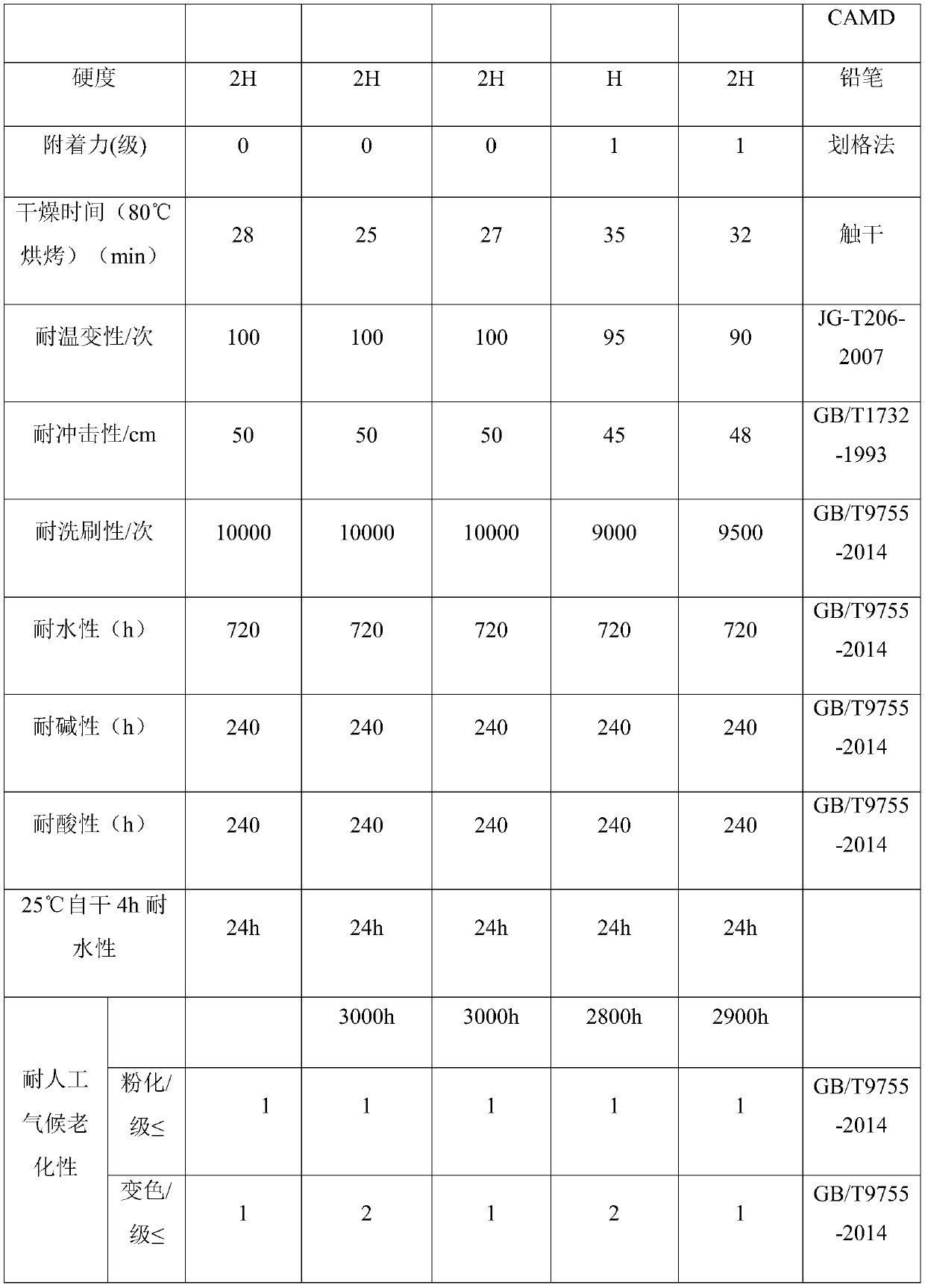

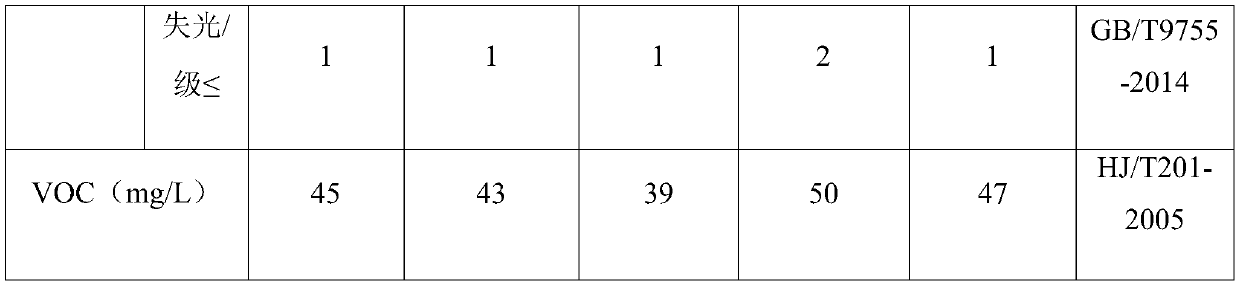

Examples

Embodiment 1

[0048] The embodiment of the present invention provides a two-component exterior wall paint, including A component and B component, and the A component includes the following raw material components in mass percentage: low-hydroxyl acrylic dispersion 10%, modified polyurethane dispersion 20%, pH adjuster 0.2%, first environmental solvent 0.8%, dispersant 1.8%, anti-sedimentation agent 0.2%, wetting and leveling agent 0.8%, thickener 0.6%, defoamer 0.6%, titanium dioxide 20 %, heavy calcium 30% and deionized water 15%;

[0049] The B component includes the following raw material components in mass percentage: 85% of water-based isocyanate curing agent and 15% of the second environmentally friendly solvent;

[0050] The mass ratio of the A component to the B component is 20:1.

[0051] Wherein, the low hydroxyl acrylic dispersion is XK110 of DSM; the modified polyurethane dispersion is Lacper 4221 and ACURE 2115 with a mass ratio of 2:1; the pH regulator is N,N-dimethylethanola...

Embodiment 2

[0058] The embodiment of the present invention provides a two-component exterior wall paint, including A component and B component, and the A component includes the following raw material components in mass percentage: low hydroxyl acrylic dispersion 12%, modified polyurethane dispersion 18%, pH regulator 0.2%, first environmental solvent 0.9%, dispersant 1.7%, anti-sedimentation agent 0.15%, wetting and leveling agent 0.9%, thickener 0.5%, defoamer 0.65%, titanium dioxide 14 %, heavy calcium 35% and deionized water 16%;

[0059] The B component includes the following raw material components in mass percentage: 90% of water-based isocyanate curing agent and 10% of the second environmental protection solvent;

[0060] The mass ratio of the A component to the B component is 22:1.

[0061] The grades of the above-mentioned components are the same as in Example 1, except that the modified polyurethane dispersion is Lacper 4221 and ACURE 2115 with a mass ratio of 4:1; the dispersa...

Embodiment 3

[0064] The embodiment of the present invention provides a two-component exterior wall paint, including A component and B component, and the A component includes the following raw material components in mass percentage: low hydroxyl acrylic dispersion 15%, modified polyurethane dispersion 15%, pH regulator 0.3%, first environmental solvent 1%, dispersant 1.5%, anti-sedimentation agent 0.1%, wetting and leveling agent 1%, thickener 0.4%, defoamer 0.7%, titanium dioxide 2 %, heavy calcium 45% and deionized water 18%;

[0065] The B component includes the following raw material components in mass percentage: 87% of water-based isocyanate curing agent and 13% of the second environmentally friendly solvent;

[0066] The mass ratio of the A component and the B component is 18:1.

[0067] The grades of the above-mentioned components are the same as in Example 1, except that the modified polyurethane dispersion is Lacper 4221 and ACURE 2115 with a mass ratio of 3:1; the dispersant is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com