Method for preparing carbon cloth surface covering copper-bismuth nanoparticles for seawater desalting

A surface-covered, bismuth-nanotechnology, which is applied in the field of preparation of copper-bismuth nanoparticles covered on the surface of carbon cloth, can solve the problems of weak light-to-heat conversion ability and poor impact resistance, and achieve effective absorption, high-efficiency water evaporation, and realization of water evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preparation method for covering copper bismuth nanoparticles on the surface of carbon cloth for seawater desalination, comprising the following steps:

[0035] (1) Activate the carbon cloth: Ultrasonic the carbon cloth in deionized water at 50-80°C for 0.5-1h, then put the carbon cloth into dilute nitric acid solution, the arrangement direction of the carbon fibers in the carbon cloth is orthogonal distribution, so The thickness of the carbon cloth is 0.294-0.333mm, the volume concentration of the dilute nitric acid is 10%, and the standing time in the dilute nitric acid solution is 15-20min.

[0036] (2) prepare the mixed solution of bismuth salt and citric acid solution, the mass ratio of bismuth salt and citric acid solution is 1-1.5:0.8-1, the carbon cloth of above-mentioned activation is put into described mixed solution to react, is heated to 75- React at 85°C for 1.8-2h, then heat to 150-170°C for 8-10h, cool to room temperature, centrifuge, wash with ethanol, ...

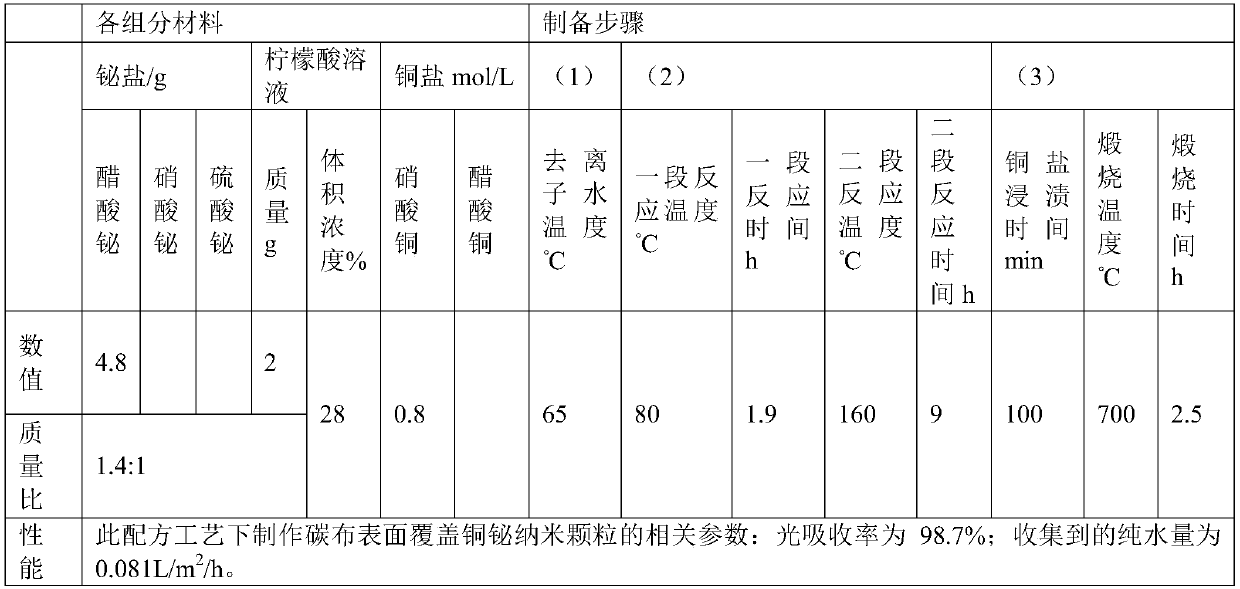

Embodiment 1

[0039]

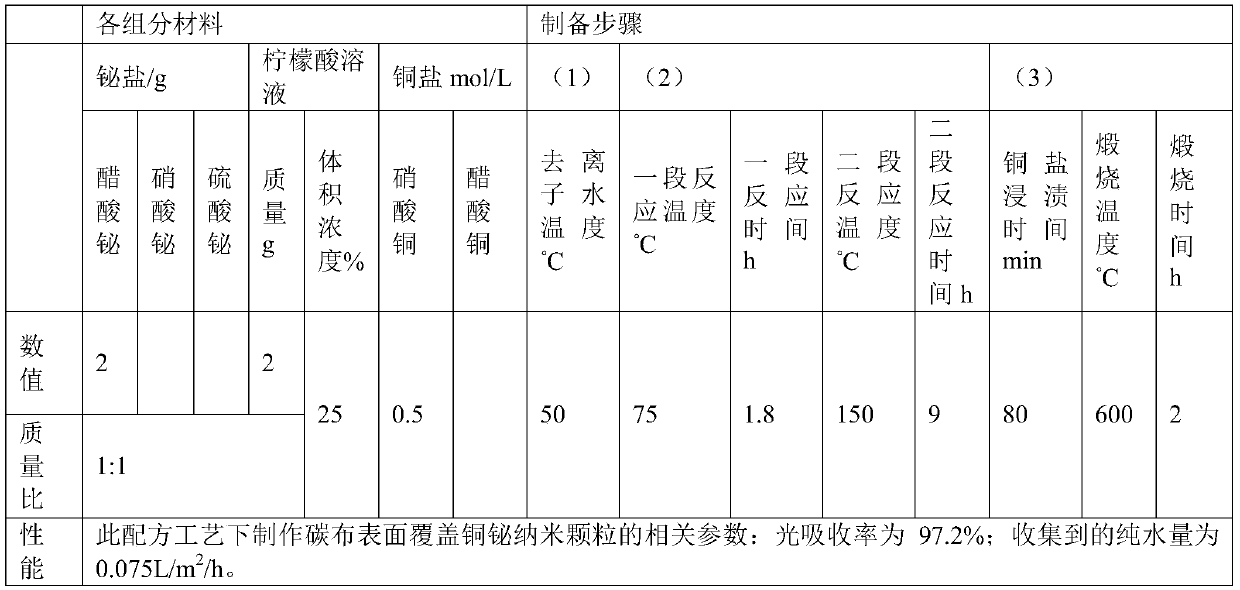

Embodiment 2

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com