Graphene and alumina whisker co-reinforced copper matrix composite material preparation method and product thereof

A technology of copper-based composite materials and alumina whiskers, which is applied in the field of preparation of copper-based composite materials, can solve problems such as inability to disperse and bond, and graphene is easy to agglomerate, and achieve excellent physical and chemical properties retention, good uniformity, and increased density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Preparation of copper matrix composites co-reinforced with graphene and alumina whiskers

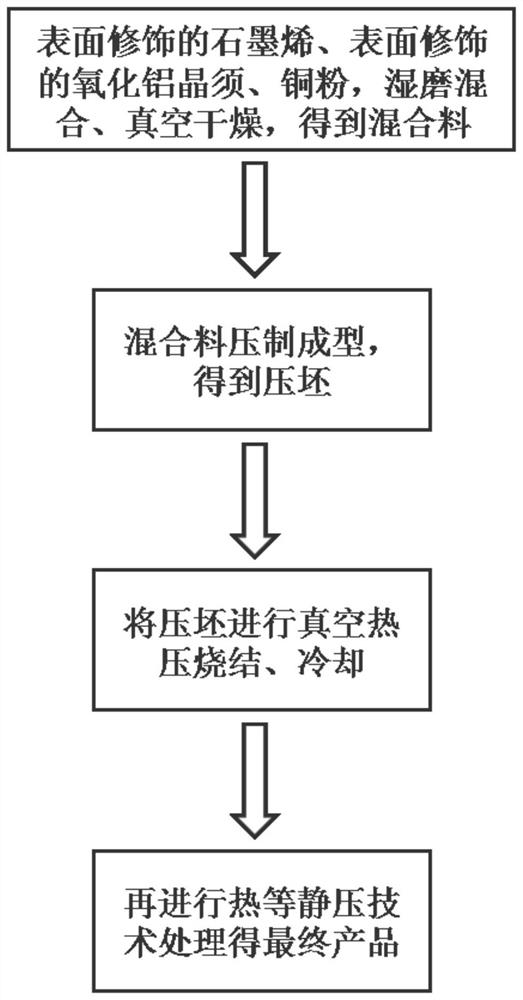

[0065] according to figure 1 The flow chart for the preparation of graphene and alumina whiskers co-reinforced copper matrix composites is shown.

[0066] First prepare graphene modified by rutin surface: step a, graphene is added to 2.0×10 -5 g / L rutin solution, stirred evenly to obtain a mixed solution, wherein the ratio of the weight of graphene to the volume of rutin aqueous solution was 1.0g:45mL.

[0067] Step b, ultrasonically disperse the mixed solution obtained in step a for 25 minutes, place it for 24 hours, filter it with suction, and dry it in vacuum to obtain graphene surface-modified by rutin.

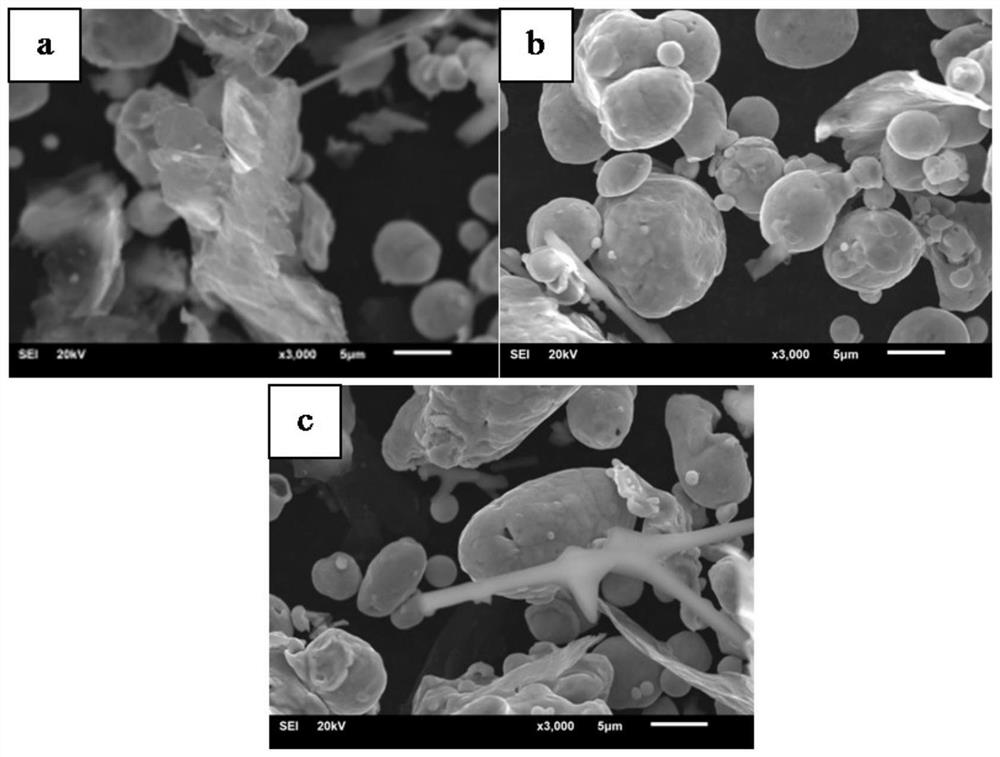

[0068] 0.1 g of the surface-modified graphene prepared in Example 1 was uniformly dispersed in 100 mL of deionized water, and after standing for 3 days, the precipitation gradually increased under the action of gravity, but the graphenes remained dispersed and did not agglo...

Embodiment 2

[0078] Preparation of copper matrix composites co-reinforced with graphene and alumina whiskers

[0079] according to figure 1 The flow chart for the preparation of graphene and alumina whiskers co-reinforced copper matrix composites is shown.

[0080] First prepare graphene modified by rutin surface: step a, graphene is added to 2.2 × 10 -5 In the rutin solution of g / L, stir evenly, obtain mixed liquor, wherein the weight of graphene and the volume ratio of rutin aqueous solution are 0.08g:40mL.

[0081] Step b, ultrasonically disperse the mixed liquid obtained in step a for 15 minutes, place it for 20 hours, filter it with suction, and dry it in vacuum to obtain graphene surface-modified by rutin.

[0082] Preparation of surface-modified alumina whiskers:

[0083] Step a, adding alumina whiskers into 2.0 g / L sodium lauryl sulfate aqueous solution, stirring evenly to obtain a mixed solution. Wherein, the ratio of the weight of aluminum oxide whiskers to the volume of sodi...

Embodiment 3

[0091] Preparation of copper matrix composites co-reinforced with graphene and alumina whiskers

[0092] according to figure 1 The flow chart for the preparation of graphene and alumina whiskers co-reinforced copper matrix composites is shown.

[0093] First prepare graphene modified by rutin surface: step a, graphene is added to 1.8×10 -5 g / L rutin solution, stirred evenly to obtain a mixed solution, wherein the ratio of the weight of graphene to the volume of rutin aqueous solution was 0.11g:50mL.

[0094] Step b, ultrasonically disperse the mixed solution obtained in step a for 30 minutes, place it for 25 hours, filter it with suction, and dry it in vacuum to obtain graphene surface-modified by rutin.

[0095] Preparation of surface-modified alumina whiskers:

[0096] Step a, adding alumina whiskers into 1.7 g / L sodium lauryl sulfate aqueous solution, stirring evenly to obtain a mixed solution. Wherein, the ratio of the weight of aluminum oxide whiskers to the volume of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com