A method for preparing a pixel-level multispectral filter

A multi-spectral and optical filter technology, applied in the fields of optical filters, optics, optical components, etc., can solve the problems of poor spectral channel unit size, poor spectral passband characteristics and limitations of optical filters, etc., to improve the passband. characteristics, reducing shadow shading effects, and ensuring the effect of dimensional integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a pixel-level multispectral filter, comprising the following steps:

[0031] S1: Use the film system design software to design the structure of the broadband filter film stack, the average transmittance of the designed passband is better than 85%, and the average transmittance of the stop band is less than 5%;

[0032] S2: cleaning the substrate, and plating a first broadband filter film stack on the substrate;

[0033] S3: Depositing a metal thin film on the first broadband filter film stack, and patterning the metal thin film, the patterned metal thin film is a metal thin film unit structure arranged periodically in an array, and the size of each metal thin film unit structure is 5-30 microns, one-to-one correspondence with the detector chip pixel;

[0034] S4: Using the patterned metal thin film as a mask layer, using a dry etching method to etch the first broadband filter film stack other than the metal mask layer to fo...

Embodiment 1

[0044] Preparation of Visible-near-infrared 4-channel pixel-level multispectral filter

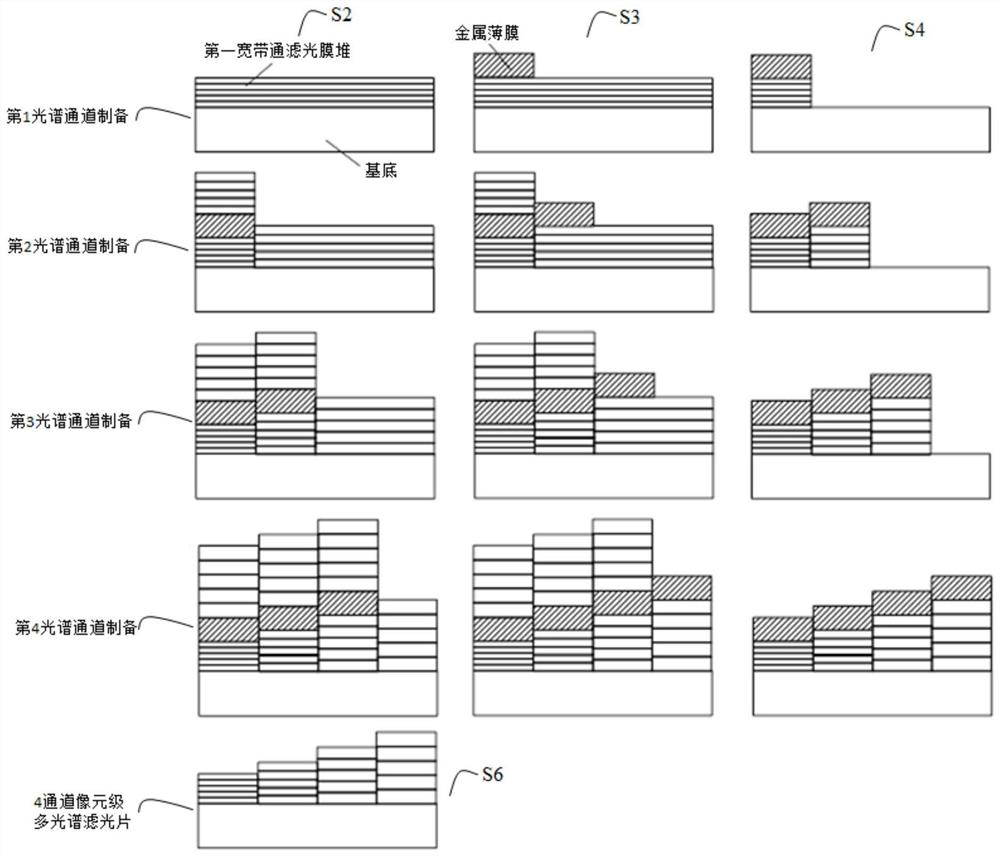

[0045] Such as figure 1 As shown, it is a schematic diagram of the preparation process of the visible and near-infrared 4-channel pixel-level multispectral filter, including the following steps:

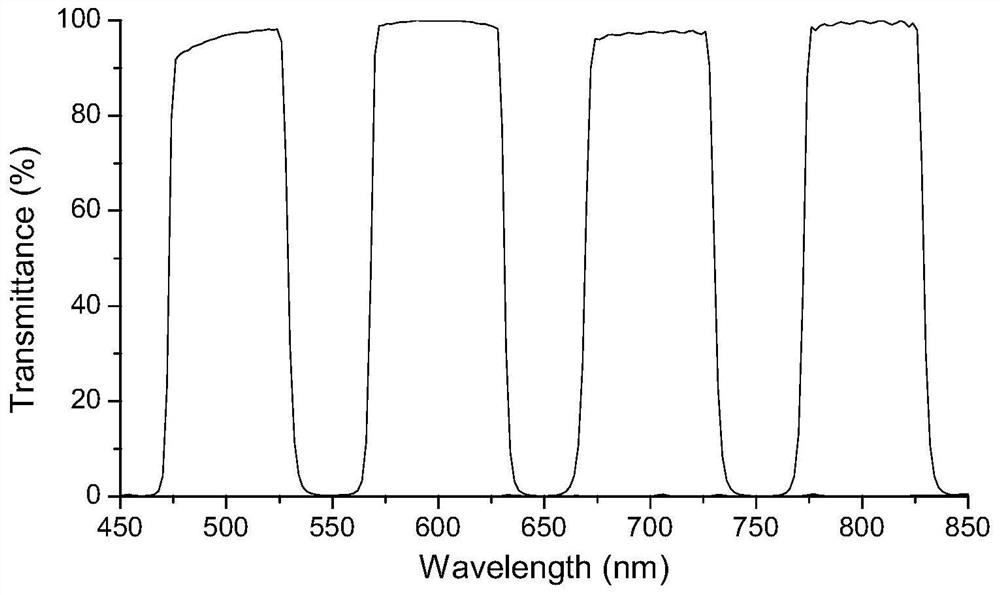

[0046] S1: Using Macleod film system design software to design a broadband filter film stack structure with a working range from 400 nm to 900 nm and a total of 4 spectral channels. The film stack structure is made of high refractive index material TiO 2 and low refractive index material SiO 2 Composed alternately, the central wavelengths of the passbands of the spectral channels are 500 nanometers, 600 nanometers, 700 nanometers, and 800 nanometers, the half-peak width of each channel is 50 nanometers, the passband transmittance is better than 95%, and the stopband average transmittance rate is less than 1%.

[0047] S2: Use ion beam-assisted electron beam evaporation coating equipment to pla...

Embodiment 2

[0054] Preparation of 6-channel short-wave infrared multi-spectral filter at pixel level

[0055] S1: Use Macleod film system design software to design a broadband filter film stack structure with a working range from 1.2 microns to 2.5 microns and a total of 6 spectral channels. The film stack structure is made of high refractive index material Si and low refractive index material Al 2 o 3 Composition, the central wavelengths of the passbands of the spectral channels are 1.4 microns, 1.6 microns, 1.8 microns, 2.0 microns, 2.2 microns, and 2.4 microns, the half-peak width of each channel is 100 nanometers, and the passband transmittance is better than 90%. The average transmittance of the stop band is less than 5%.

[0056] S2: Use the magnetron sputtering coating equipment to plate the designed first broadband filter film stack on the clean K9 glass substrate, that is, the film stack with a central wavelength of 1.4 microns. When depositing the film, the vacuum degree is 5×...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com