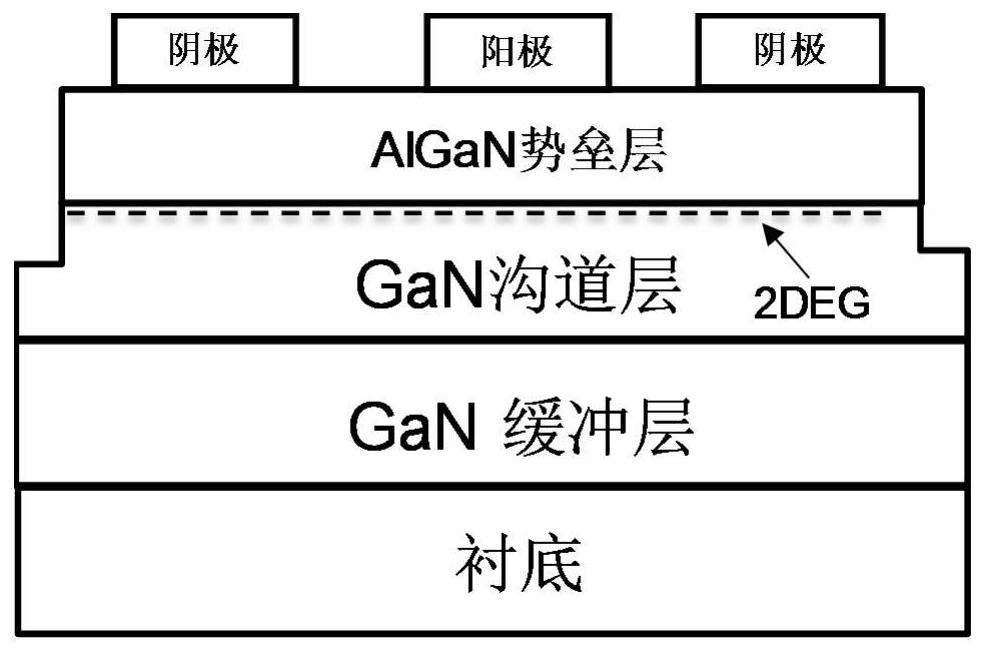

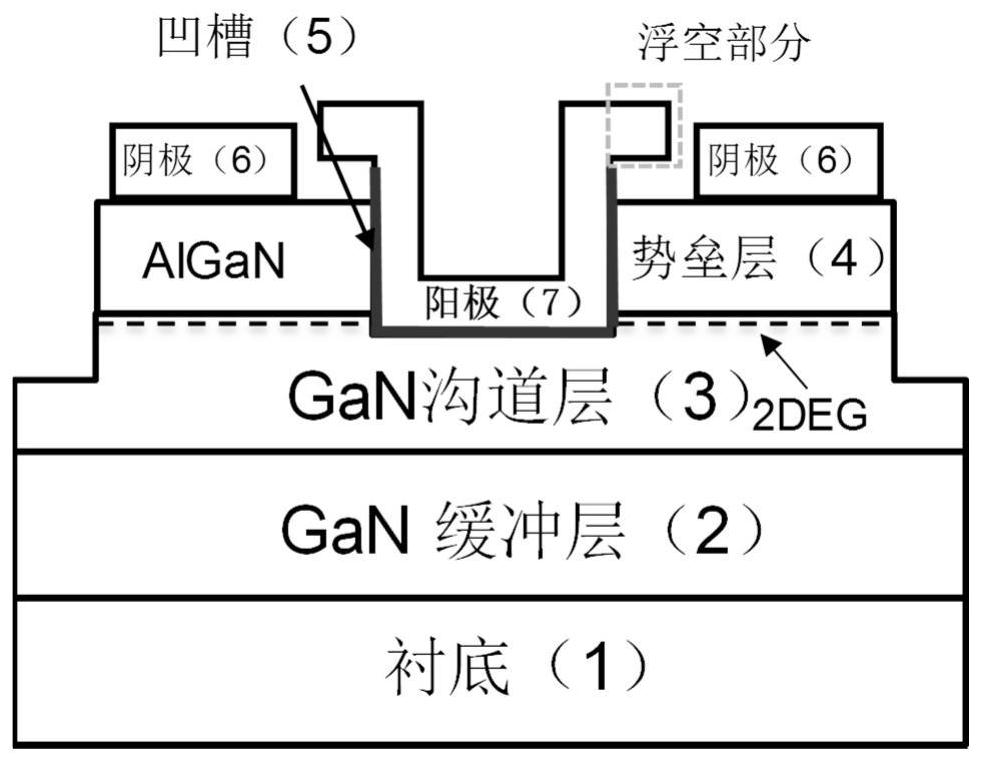

Gan microwave diode with floating anode edge and its preparation method

A diode and anode technology, applied in the field of microelectronics, can solve problems such as affecting performance, and achieve the effect of improving the yield, the method is simple and effective, and the operability is strong

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

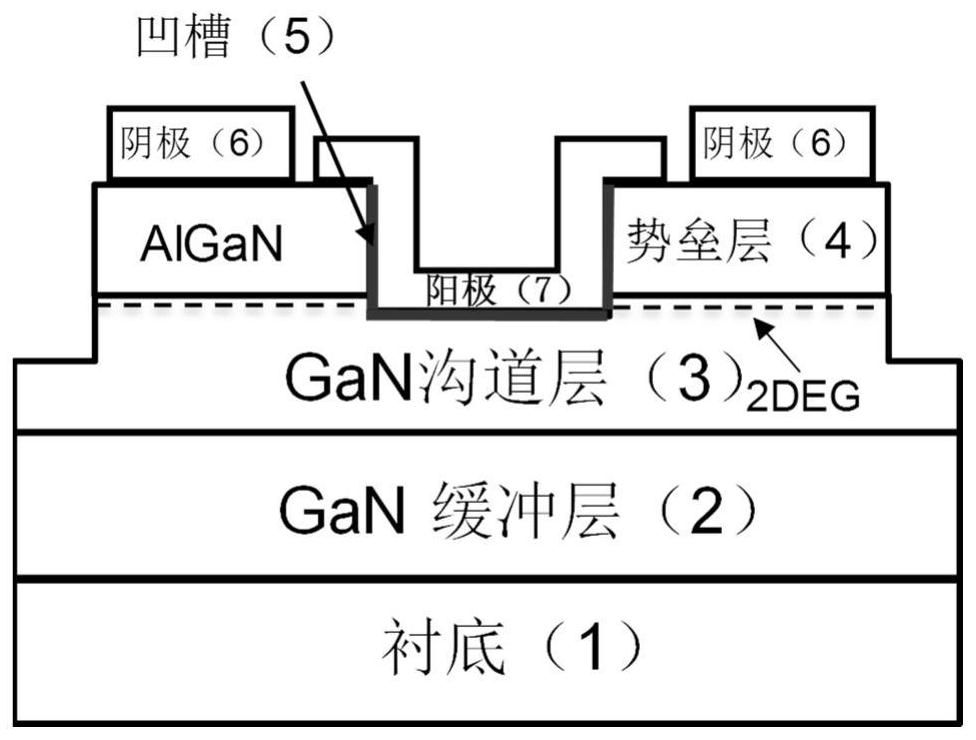

Examples

Embodiment 1

[0042] Example 1, making the anode groove etched to 5nm below the AlGaN / GaN interface, the thickness of the anode Ni / Au metal is 30 / 200nm, and the gap between the anode above the groove edge barrier layer and the lower barrier layer is 200nm. Edge floating GaN microwave diode.

[0043] Step 1, epitaxial wafer cleaning, such as Figure 4 (a).

[0044] The epitaxial wafer with a SiC substrate with a thickness of 400 μm and an AlGaN / GaN structure with a GaN buffer layer thickness of 1 μm was soaked in HF acid solution or HCl acid solution for 30 seconds, and then put into acetone solution, absolute ethanol solution and Each was ultrasonically cleaned in deionized water for 5 min, and then dried with nitrogen.

[0045] Step 2, make GaN microwave diode cathode, such as Figure 4 (b).

[0046] 2a) On a clean epitaxial wafer, perform uniform coating, baking, photolithography and development of the cathode area of the device in sequence, and use electron beam evaporation equipment...

Embodiment 2

[0062] Example 2, making the anode groove etched to 10nm below the AlGaN / GaN interface, the anode Ni / Au metal thickness is 45 / 150nm, and the gap between the anode above the groove edge barrier layer and the lower barrier layer is 300nm. Edge floating GaN microwave diode.

[0063] Step 1, epitaxial wafer cleaning, such as Figure 4 (a).

[0064] The epitaxial wafer with the Si substrate with a thickness of 800 μm and the AlGaN / GaN structure with a GaN buffer layer thickness of 6 μm was soaked in HF acid solution or HCl acid solution for 30 seconds, and then put into acetone solution, absolute ethanol solution and Each was ultrasonically cleaned in deionized water for 5 min, and then dried with nitrogen.

[0065] Step 2, making GaN microwave diode cathode, such as Figure 4 (b).

[0066] The specific implementation of this step is the same as that of step 2 in Embodiment 1.

[0067] Step 3, making countertop isolation, such as Figure 4 (c).

[0068] The specific implemen...

Embodiment 3

[0078] Example 3, making the anode groove etched to 15nm below the AlGaN / GaN interface, the anode Ni / Au metal thickness is 60 / 100nm, and the gap between the anode above the groove edge barrier layer and the lower barrier layer is 100nm. Edge floating GaN microwave diode.

[0079] Step A, epitaxial wafer cleaning, such as Figure 4 (a).

[0080] Put the epitaxial wafer of AlGaN / GaN structure with a sapphire substrate with a thickness of 600 μm and an AlGaN gradient buffer layer with a thickness of 3 μm in HF acid solution or HCl acid solution for 30 seconds, then put it in acetone solution, absolute ethanol The solution and deionized water were ultrasonically cleaned for 5 min each, and then dried with nitrogen.

[0081] Step B, making GaN microwave diode cathode, such as Figure 4 (b).

[0082] The specific implementation of this step is the same as that of step 2 in Embodiment 1.

[0083] Step C, making countertop isolation, such as Figure 4 (c).

[0084] The specific...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com