Synchronous denitrification, dephosphorization and oxygenation composite material as well as preparation method and application thereof

A technology for simultaneous denitrification, phosphorus removal, and composite materials, applied in the field of simultaneous denitrification, phosphorus removal, and oxygen-enhancing composite materials and their preparation, can solve problems such as increasing treatment procedures and costs, disturbing water ecosystems, and destroying water body stratification. Excellent denitrification, phosphorus removal and oxygenation, low production cost and high ecological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

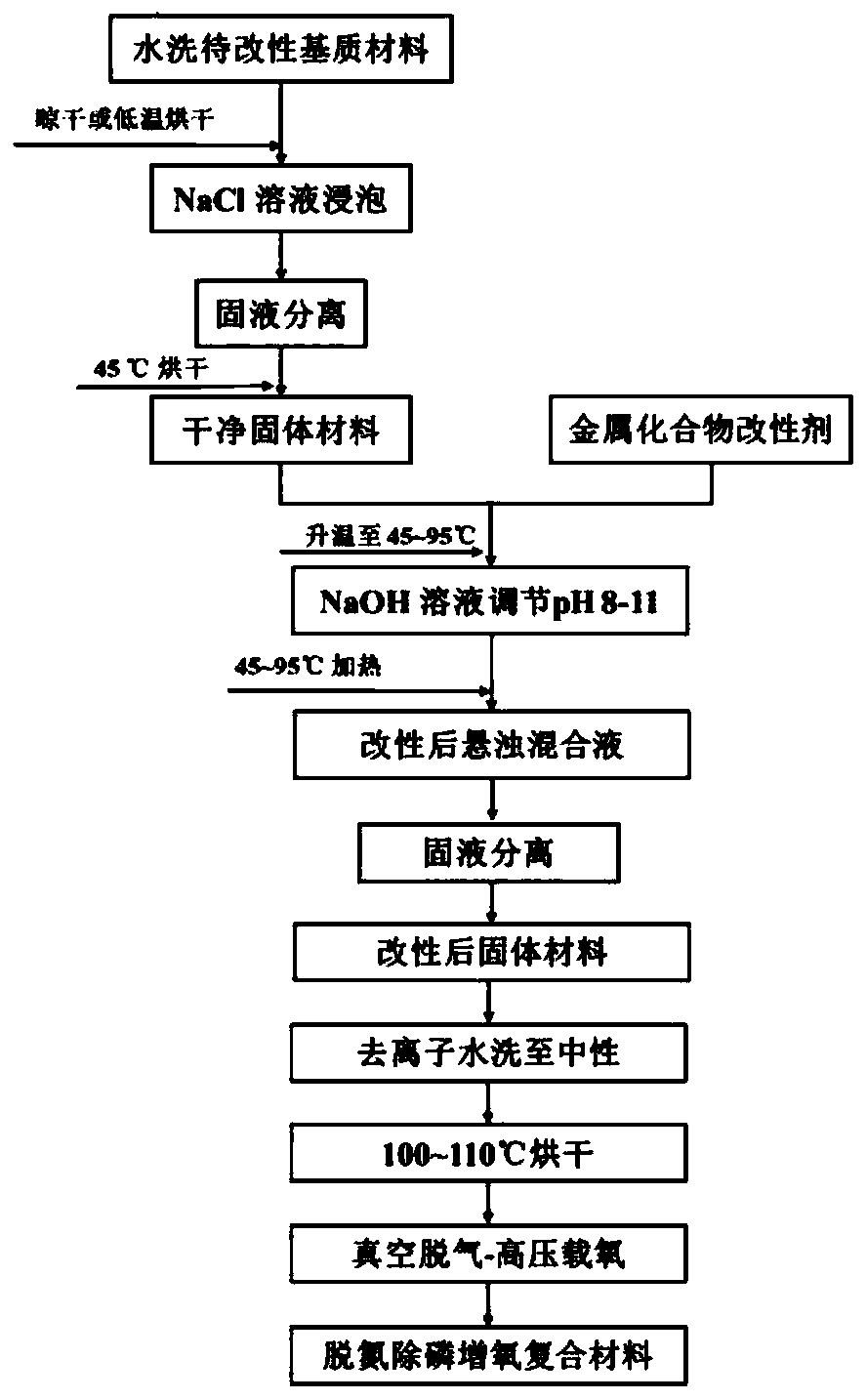

[0029] The invention provides a method for preparing a synchronous denitrification, dephosphorization and oxygenation composite material, comprising the following steps:

[0030] soaking the modified matrix material in a sodium chloride solution to obtain a pretreated modified matrix material;

[0031] Mixing the pretreated modified matrix material with a modifier for modification to obtain a modified solid material;

[0032] The modified solid material is loaded with micro-nano bubbles to obtain a synchronous denitrification, dephosphorization and oxygenation composite material;

[0033] The modified matrix material is porous biomass material and / or mineral material;

[0034] The modifying agent is a metal compound, and the metal compound is one or two of lanthanum compound, aluminum compound and iron compound.

[0035] In the present invention, unless otherwise specified, the required preparation materials are commercially available products well known to those skilled in ...

Embodiment 1

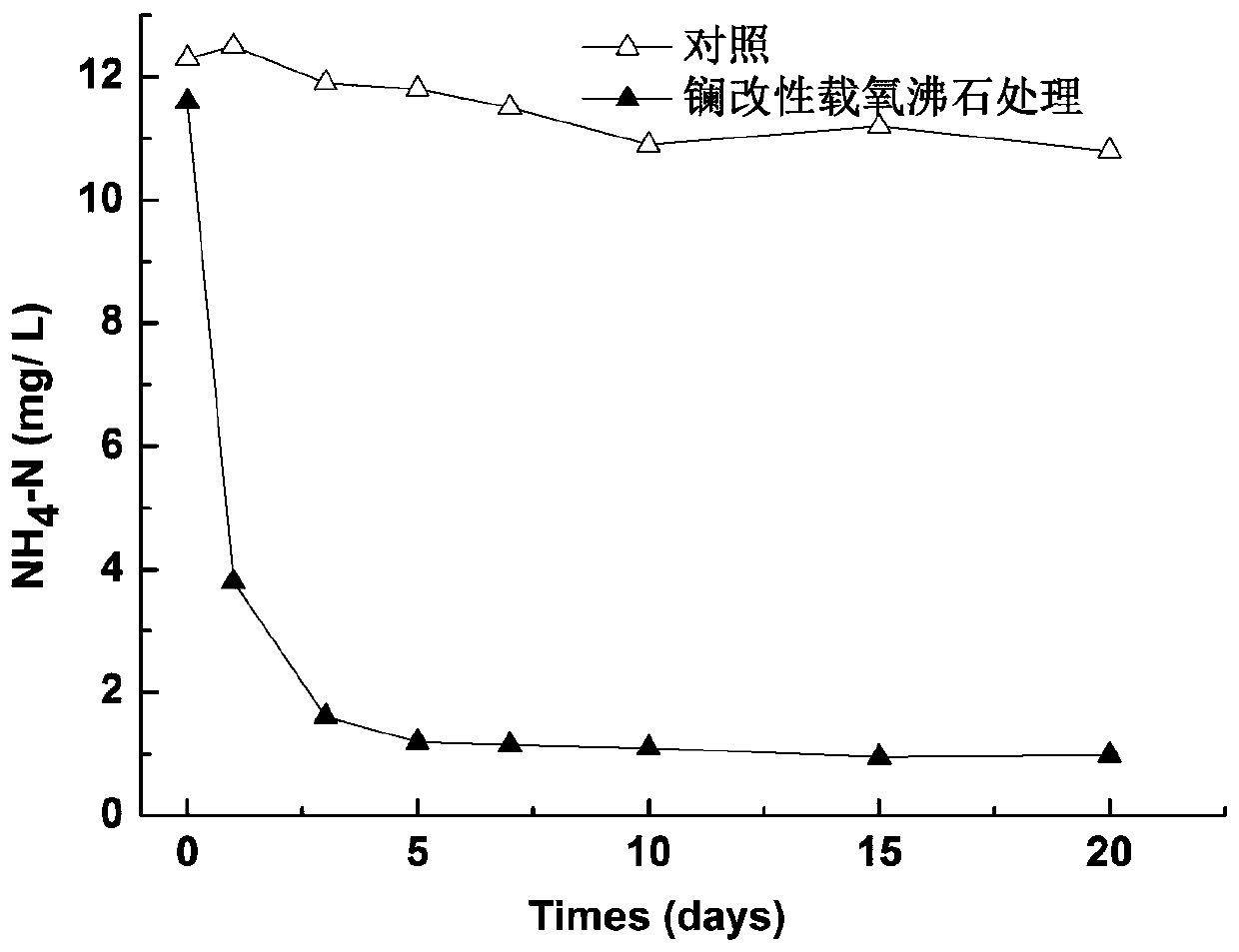

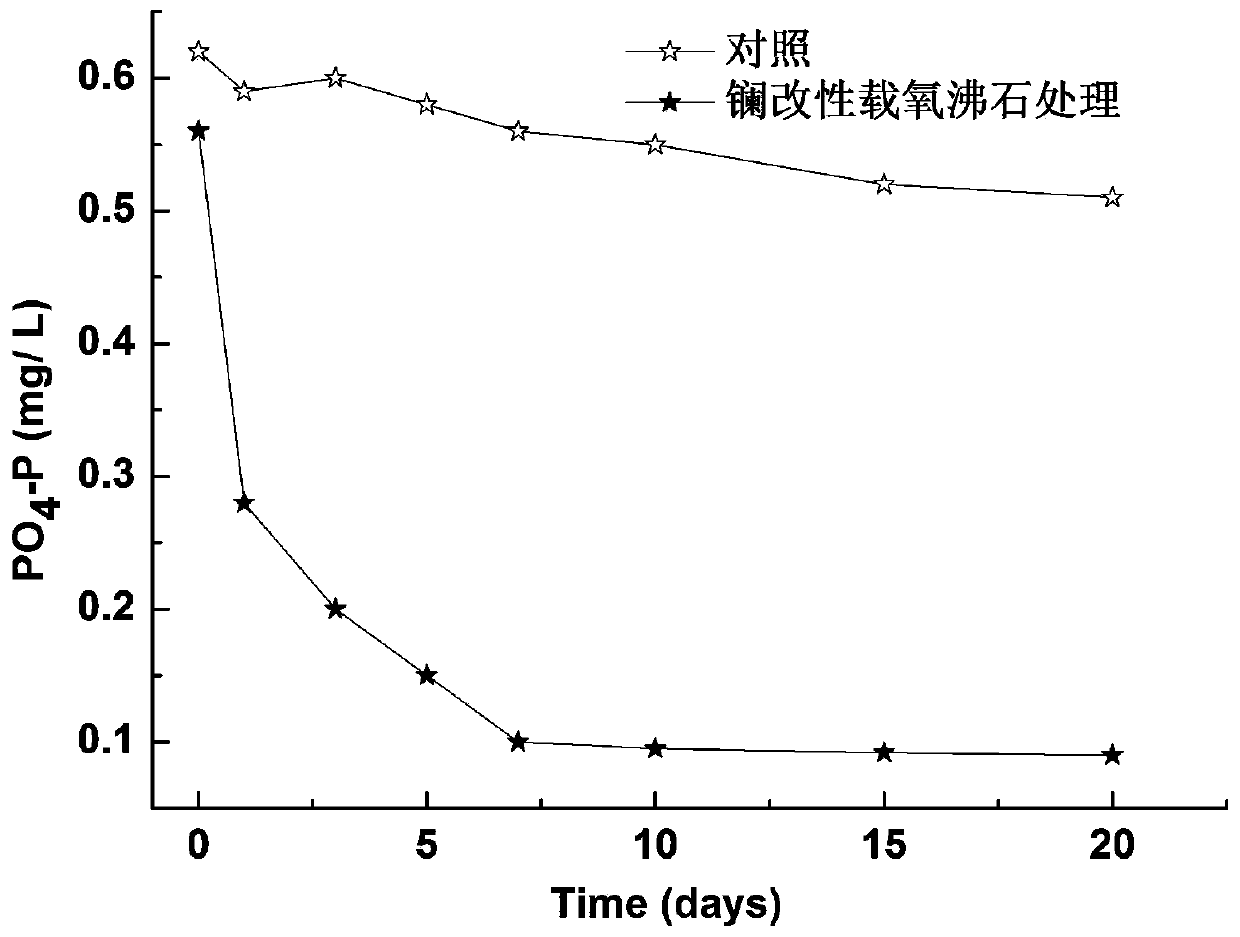

[0052] Synthesize the lanthanum-modified oxygen-carrying zeolite composite material according to the following steps, and verify the effect of the material on removing nitrogen, phosphorus and increasing oxygen in the column system:

[0053] Weigh 200g of zeolite with a particle size of 1-3mm, repeatedly wash with deionized water to remove impurities on the surface of zeolite particles, and dry at 45°C; prepare 2000mL of 1.0mol / L NaCl solution; pour the dried zeolite into NaCl solution and mix well , magnetically stirred for 6 hours to carry out ion exchange; the obtained solid-liquid mixture was subjected to solid-liquid separation, the solid particles were washed with deionized water, and dried at 45°C to obtain dried zeolite;

[0054] Weigh 5g of lanthanum chloride into a 500mL Erlenmeyer flask, add 100mL of deionized water, fully dissolve in a water bath at 50°C, add 95g of dried zeolite, stir evenly, adjust the pH of the system to 10.0 with 2mol / L NaOH solution, and heat u...

Embodiment 2

[0060] In this example, the lanthanum-aluminum modified oxygen-carrying zeolite composite material was synthesized according to the following steps, and the effect of removing nitrogen, phosphorus and increasing oxygen was verified experimentally in the column system:

[0061]Weigh 200g of zeolite with a particle size of 1-3mm, repeatedly wash with deionized water to remove impurities on the surface of zeolite particles, and dry at 45°C; prepare 2000mL of 1.0mol / L NaCl solution; pour the above-mentioned dried zeolite into NaCl solution, mix Uniformly, magnetically stirred for 6 hours to carry out ion exchange; the obtained solid-liquid mixture was subjected to solid-liquid separation, the solid particles were washed with deionized water, and dried at 45°C to obtain dried zeolite; 5g of lanthanum chloride and 25g of aluminum chloride were weighed to Add 100mL deionized water to a 500mL Erlenmeyer flask, fully dissolve in a water bath at 50°C, add 70g of dried zeolite, stir well,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com