Ultrasonic assistance based connecting method for light alloy and thermoplastic composite

A composite material and lightweight alloy technology, applied in the field of metal and composite material connection, can solve problems such as weak links of joints, fiber structure damage, long time, etc., to reduce the peak residual stress, improve tensile strength, and improve bonding reaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

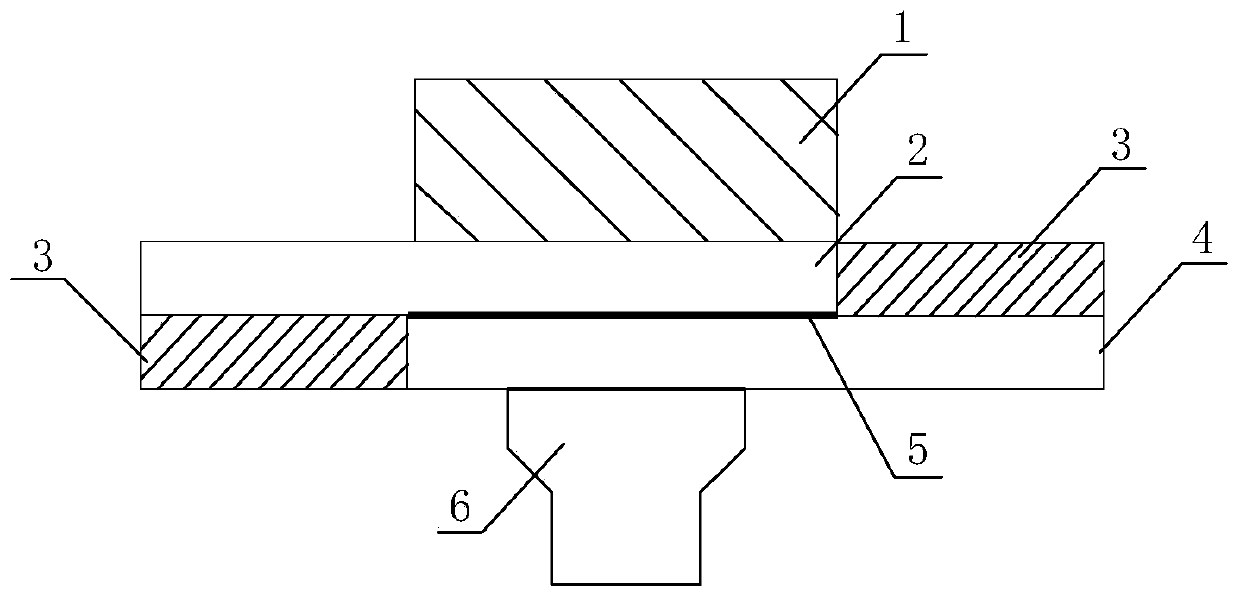

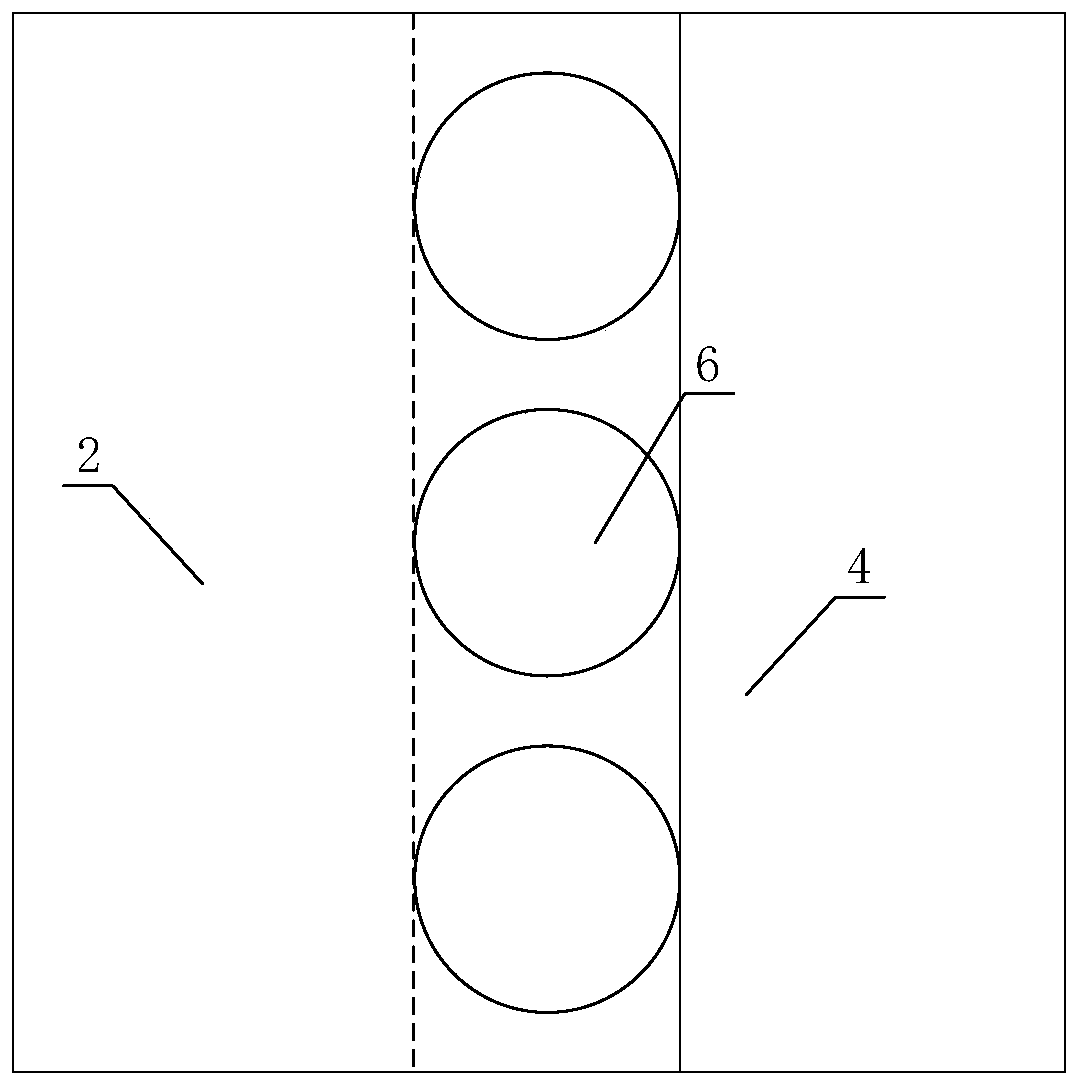

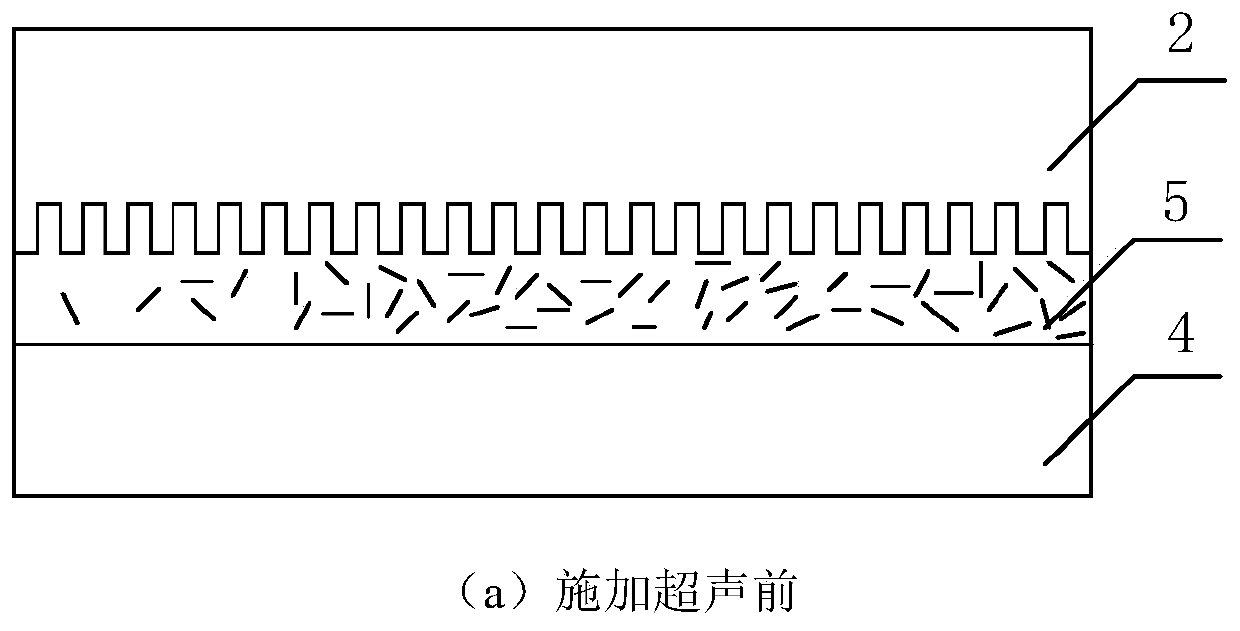

[0036] Such as Figure 1-3 As shown, the magnesium alloy and the carbon fiber reinforced PEI composite material are connected by a method for connecting the light alloy 2 and the thermoplastic composite material 4 based on ultrasonic assistance of the present invention, which specifically includes the following steps:

[0037] Step 1. Before the connection, the surface of the light alloy 2 to be connected is treated by mechanical treatment or electrochemical treatment to form microscopic channels on the surface or increase the surface roughness. The metal surface is anodized so that the molten composite material can enter the porous layer and form Mechanical interlocking; the metal surface is roughened, which will increase the roughness of the metal surface, so as to increase the connection area, and facilitate the joining of the molten thermoplastic composite material 4 to be connected and the light alloy 2; the magnesium alloy to be connected in this embodiment The surface i...

Embodiment 2

[0044]A method for connecting titanium alloys and carbon fiber reinforced PEI composite materials based on an ultrasonic-assisted light alloy 2 and thermoplastic composite material 4 of the present invention is also used, specifically including the following steps:

[0045] Step 1. Before the connection, the surface of the light alloy 2 to be connected is treated by mechanical treatment or electrochemical treatment to form microscopic channels on the surface or increase the surface roughness. The metal surface is anodized so that the molten composite material can enter the porous layer and form Mechanical interlocking; the metal surface is roughened, which will increase the roughness of the metal surface, so as to increase the connection area, and facilitate the joining of the molten thermoplastic composite material 4 to be connected and the light alloy 2; the titanium alloy to be connected in this embodiment The surface is anodized;

[0046] Step 2, place the parts to be conn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com