High-temperature salt-resistant fluid loss additive modified gum resin for drilling fluids

A technology of fluid loss reducer and drilling fluid, which is applied in the directions of drilling compositions, chemical instruments and methods, can solve problems such as poor temperature resistance and salt resistance, and achieve low production cost, good temperature resistance, and good temperature resistance. Effect of salt resistance and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

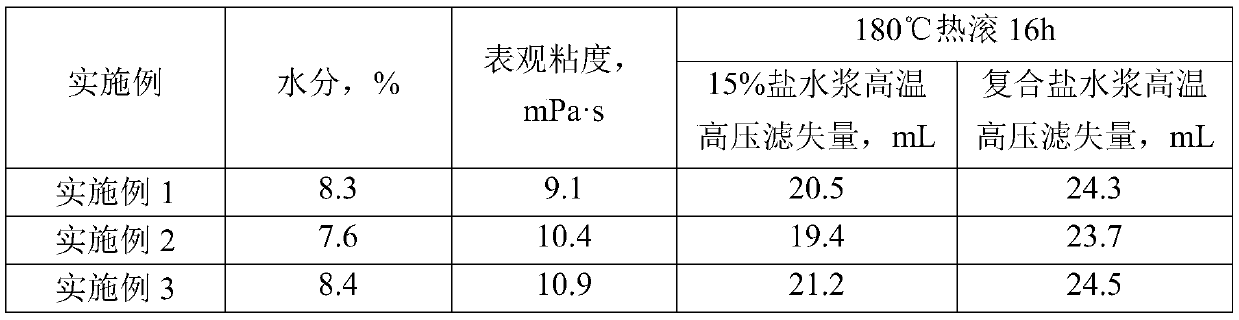

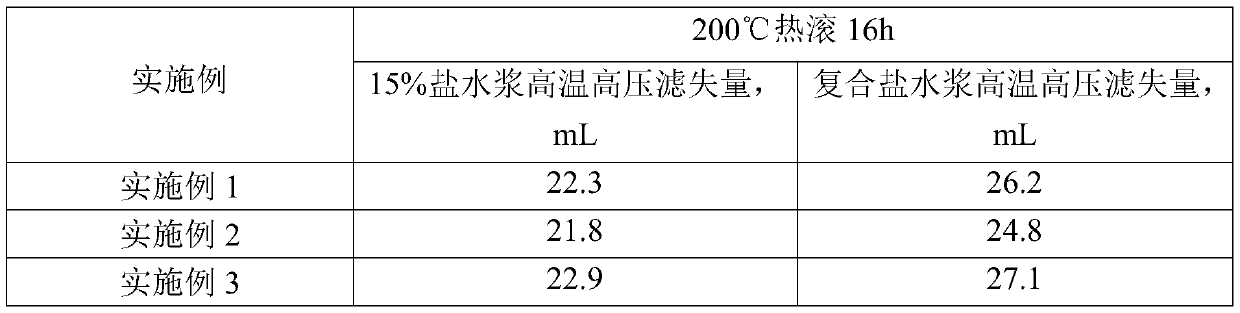

[0018] Embodiment 1: The high-temperature salt-resistant fluid loss reducer modified gum resin for drilling fluid according to the present invention is made of the following raw materials in parts by mass: 220 parts of clear water, 35 parts of sodium methallyl sulfonate , 10 parts of N,N-dimethylacrylamide, 0.7 parts of temperature-resistant monomer 4-vinylguaiacol, 25 parts of methacryloyloxyethyltrimethylammonium chloride, chelating agent citric acid 5 parts of sodium, 0.5 part of initiator, 35 parts of gum resin, 10 parts of 40% sodium hydroxide solution, 10 parts of propylene oxide, 20 parts of additive namely polyvinyl alcohol powder; Among the above initiators, azo initiator and The mass ratio of the redox initiator is 3:2, the azo initiator is selected from azobisisobutyronitrile, and in the redox initiator, the oxidizing agent is selected from potassium persulfate, the reducing agent is selected from sodium bisulfite, the oxidizing agent and the reducing agent The mass...

Embodiment 2

[0020] Embodiment 2: The high-temperature salt-resistant fluid loss reducer modified gum resin for drilling fluid according to the present invention is made of the following raw materials in parts by mass: 230 parts of clear water, 30 parts of sodium methallyl sulfonate , 15 parts of N,N-dimethylacrylamide, 1.0 parts of temperature-resistant monomer namely 4-vinylguaiacol, 25 parts of methacryloyloxyethyltrimethylammonium chloride, chelating agent namely citric acid 4 parts of sodium, 0.7 parts of initiator, 30 parts of gum resin, 9 parts of 40% sodium hydroxide solution, 7.5 parts of propylene oxide, 15 parts of polyvinyl alcohol powder as additive; among the above initiators, azo initiators are selected Azobisisobutyronitrile, the combination of two kinds of raw materials of azobisisoheptanonitrile, in redox initiator, oxidizing agent is selected potassium persulfate for use, and reducing agent is selected sodium bisulfite for use, and the mass ratio of oxidizing agent and re...

Embodiment 3

[0022] Embodiment 3: The high-temperature salt-resistant fluid loss reducer modified gum resin for drilling fluid according to the present invention is made of the following raw materials in parts by mass: 240 parts of clear water, 35 parts of sodium methallyl sulfonate , 15 parts of N,N-dimethylacrylamide, 0.5 parts of temperature-resistant monomer 4-vinylguaiacol, 25 parts of methacryloyloxyethyltrimethylammonium chloride, chelating agent citric acid 5 parts of sodium, 1.0 part of initiator, 35 parts of gum resin (gum arabic), 10 parts of 40% sodium hydroxide solution, 10 parts of propylene oxide, 20 parts of polyvinyl alcohol powder as an additive; The nitrogen initiator is selected from the combination of azobisisobutyronitrile and azobisisoheptanonitrile. Among the redox initiators, the oxidizing agent is selected from ammonium persulfate, and the reducing agent is selected from sodium bisulfite. The quality of the oxidizing agent and reducing agent The ratio of azobisiso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com