Preparation method of alpha-MnO2 catalyst for catalyzing oxidation of volatile organic compounds

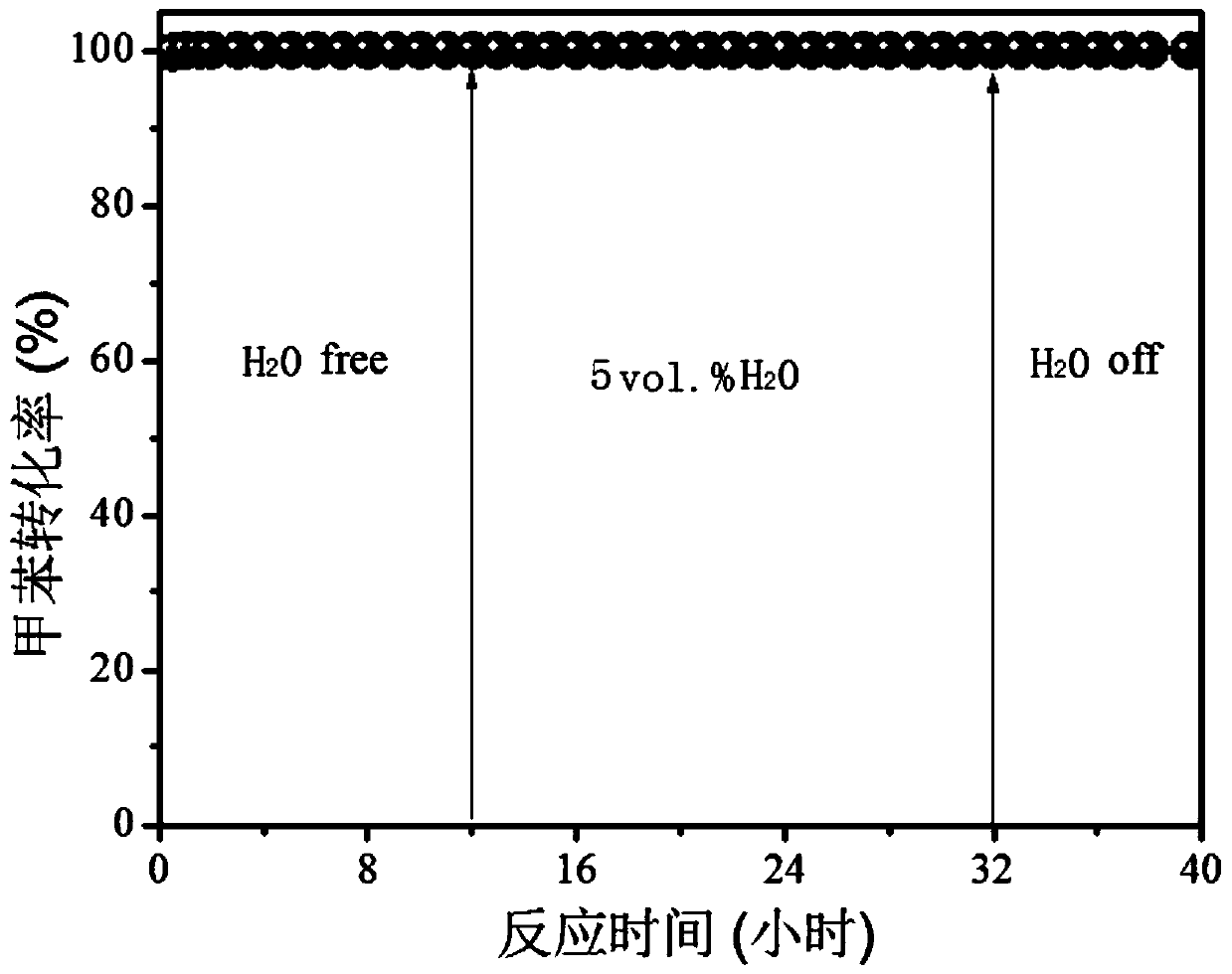

An organic compound, volatile technology, applied in the field of α-MnO2 catalyst preparation, can solve the problems of poor stability and water resistance, low reactivity, etc., and achieve good water resistance, good repeatability, and short synthesis cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

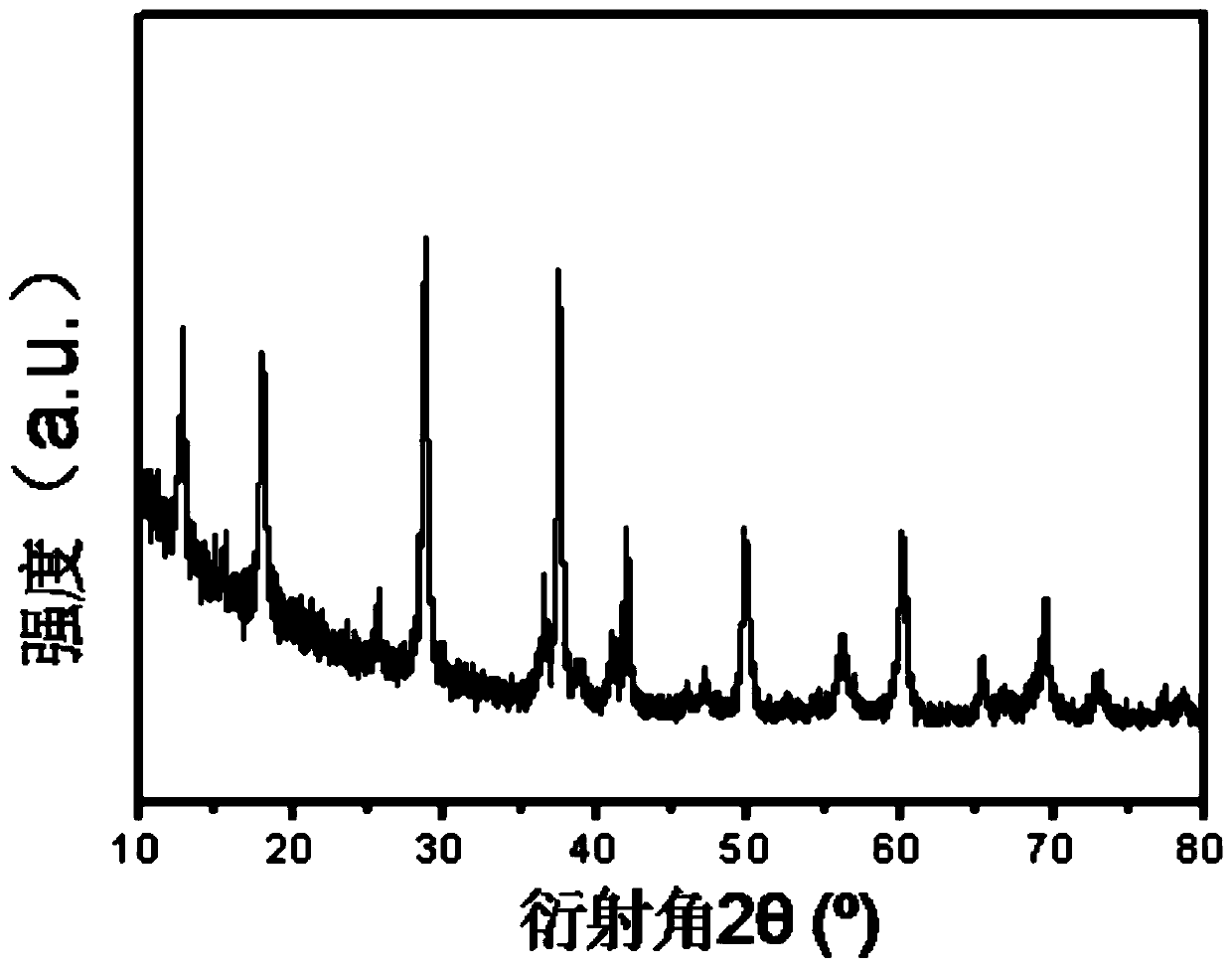

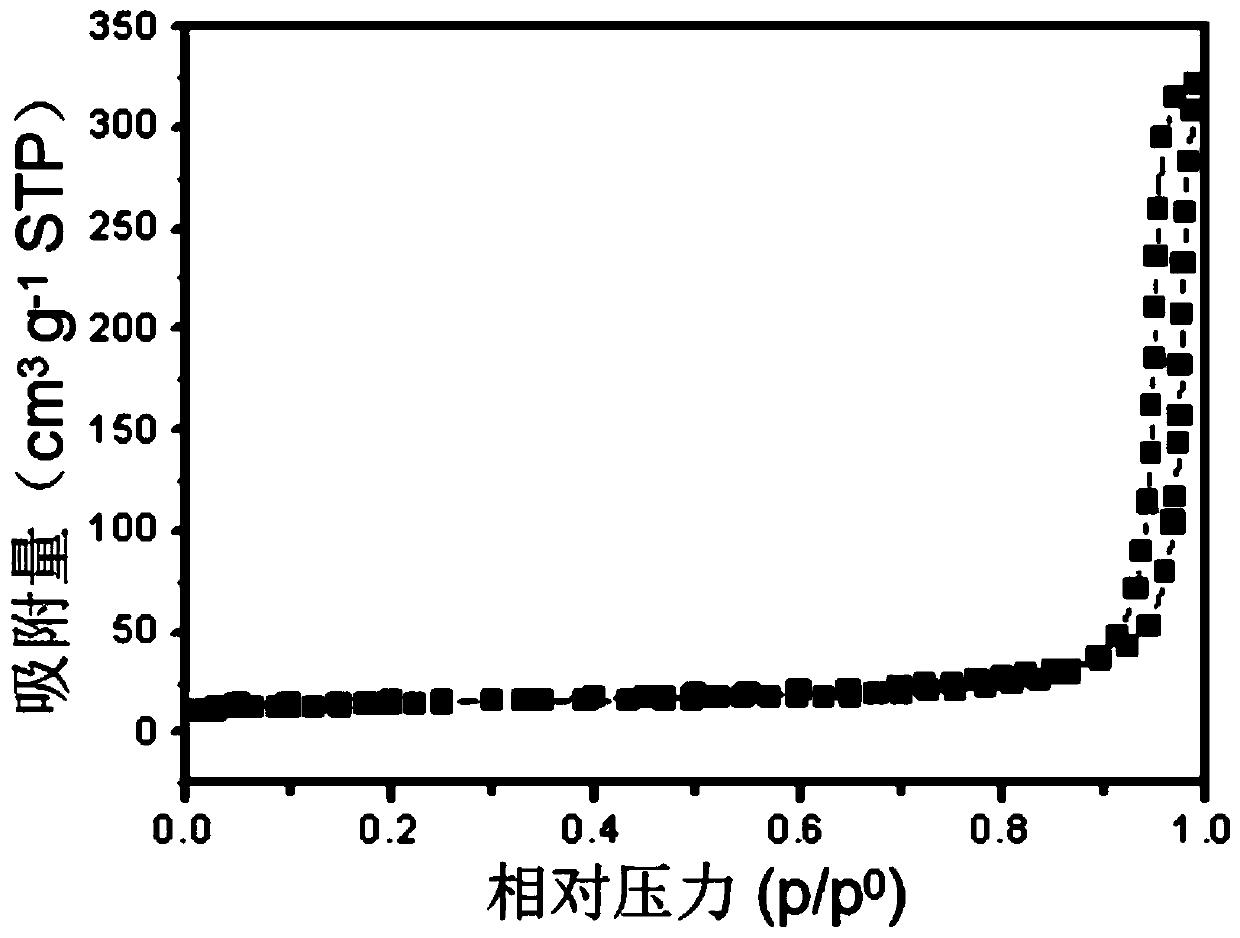

[0021] Specific implementation mode 1: α-MnO that catalyzes the oxidation of volatile organic compounds in this implementation mode 2 The preparation method of catalyst is carried out according to the following steps:

[0022] 1. Add potassium permanganate to deionized water, perform ultrasonic treatment and magnetic stirring in turn to obtain solution A; solution A is purple;

[0023] 2. Add ethylene glycol to the deionized water, and then adjust the pH value to 7.0-12.0 under the conditions of water bath and magnetic stirring to obtain solution B; solution B is a weakly alkaline transparent solution;

[0024] 3. Add solution A dropwise to solution B, react for 0.5-2 hours in a 20-60°C water bath and stir, then add ethylene glycol, and react in a 20-60°C water bath and stir for 0.5-12h, Obtain suspension C; Suspension C is dark brown;

[0025] Four, filter the suspension C obtained in step 3 to obtain a solid product, wash the solid product repeatedly with deionized water u...

specific Embodiment approach 2

[0031] Embodiment 2: This embodiment differs from Embodiment 1 in that the ratio of the mass of potassium permanganate to the volume of deionized water in step 1 is (1-3) g: (20-50) ml. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the ultrasonic treatment time in step 1 is 5-15 minutes. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com