Turbine blade air film hole precision forming method

A turbine blade and precision forming technology, applied in chemical instruments and methods, self-solidification method, casting mold composition, etc., can solve the problems of uncontrollable machining dimensional accuracy, inability to process special-shaped holes and multi-angle inclined holes, and low machining efficiency. , to reduce the recast layer and micro-cracks, speed up the rapid research and development, and eliminate the positioning error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] For the precision forming method of the air film hole of the turbine blade, the steps are as follows:

[0030] 1) Manufacture of turbine blade resin mold

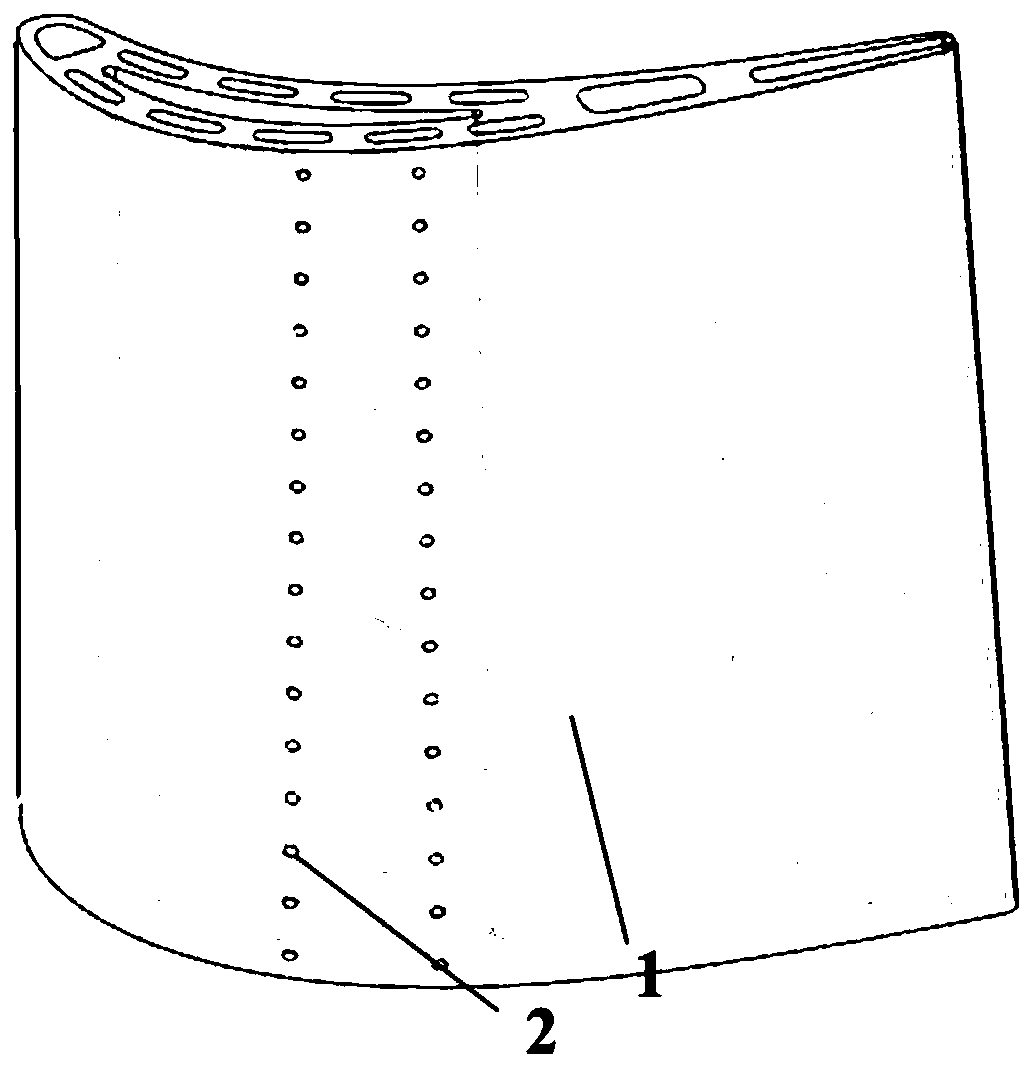

[0031] The present invention utilizes light-curing rapid prototyping technology to manufacture resin molds. First, a resin mold CAD model is designed using commercial three-dimensional software, and a two-dimensional slice file with a layered thickness of 0.07mm is generated, and the resin mold is quickly and automatically manufactured under the control of the slice file. For stereolithography prototypes, see figure 1 , where 1 is the blade body, and 2 is the air film hole structure. The manufactured turbine blade resin mold has high precision, high rigidity, and good surface quality, and can be used as a molding mold for ceramic ligands.

[0032] 2) Prepare ceramic slurry

[0033] First, dissolve the organic matter in deionized water, add dispersant, uniformly mixed alumina ceramic powder and mineralizer powder i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com