Method for preparing two-dimensional boron hydride nanosheet

A technology of boron hydride and nanosheets, applied in chemical instruments and methods, inorganic chemistry, boron compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

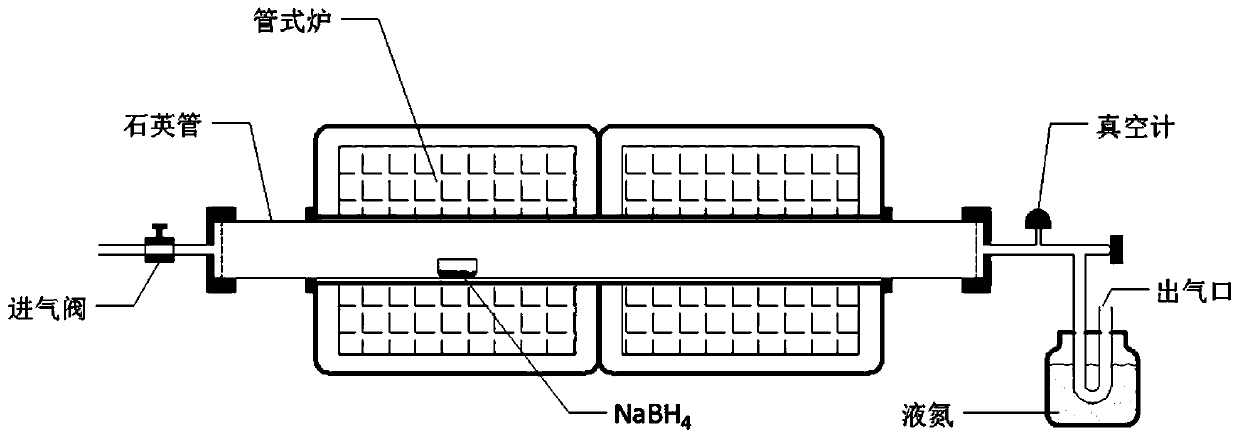

[0028] The preparation of two-dimensional boron hydride nanosheets by directly thermally decomposing a solid boron source through a substrate-free method includes the following preparation steps:

[0029] (1) 0.5g boron source NaBH 4 The powder is placed in the temperature zone on the left side of the quartz tube;

[0030] (2) Seal the tube furnace system, turn on the vacuum pump to pump the air pressure of the quartz tube to the limit vacuum state of 0.1Pa, and keep it for 20min;

[0031] (3) The hydrogen flow meter is set to 10 sccm, and hydrogen is injected into the quartz tube vacuum cavity;

[0032] (4) Adjust the exhaust valve to keep the air pressure inside the cavity at 50Pa;

[0033] (5) Raise the temperature in the left temperature zone to 490°C in 49 minutes, and anneal the boron source for 2 hours;

[0034] (6) Heat up the left temperature zone again, set it to 550°C for 15 minutes, and let it react for 300 minutes;

[0035] (7) Use fan cooling to quickly drop ...

Embodiment 2

[0041] The preparation of two-dimensional boron hydride nanosheets by substrate-free direct thermal decomposition method includes the following preparation steps:

[0042] (1) 0.5g boron source NaBH 4 The powder is placed in the temperature zone on the left side of the quartz tube;

[0043] (2) Seal the tube furnace system, turn on the vacuum pump to evacuate the air pressure of the quartz tube to the ultimate vacuum state of 0.1 Pa, and keep it for 20 minutes;

[0044] (3) The hydrogen flow meter is set to 10 sccm, and hydrogen is injected into the quartz tube vacuum cavity;

[0045] (4) Adjust the exhaust valve to keep the air pressure inside the cavity at 50Pa;

[0046] (5) Raise the temperature in the left temperature zone to 490°C in 49 minutes, and anneal the boron source for 2 hours;

[0047] (6) Raise the temperature of the left temperature zone again, set it to 550°C for 15 minutes, and let it react for 30 minutes;

[0048] (7) Continue to increase the temperature...

Embodiment 3

[0055] The preparation of two-dimensional boron hydride nanosheets by substrate-free direct thermal decomposition method includes the following preparation steps:

[0056] The basic method is similar to Example 2, except that the reaction time in step 7 is 60min, and the difference between step 11 and Example 2 is that the solution to be processed has been changed to hydrochloric acid and sodium hydroxide, and an insoluble solution is obtained after drying. Ultrastable two-dimensional boron hydride nanosheets in acid and alkali solutions, whose X-ray photoelectron spectroscopy is shown in Figure 6 As shown, it can be clearly seen that the characteristic peak of B1s appears at 187.5eV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com