Iodine-doped graphene-coated graded-hole Prussian blue nanospheres and preparation method and application of hierarchical pore Prussian blue nanosphere

A graphene-wrapped, Prussian blue technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of cycle instability, low charge and discharge capacity, poor conductivity, etc. Good chemical properties, good rate performance, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

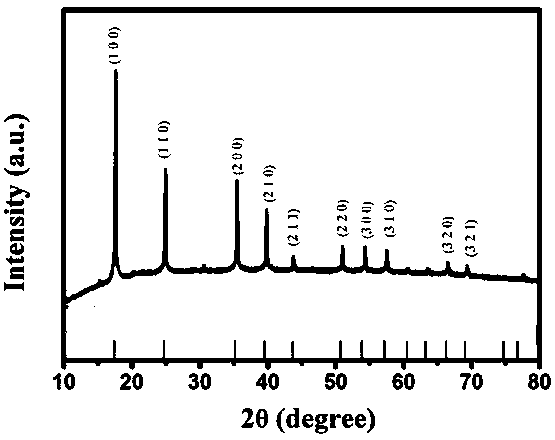

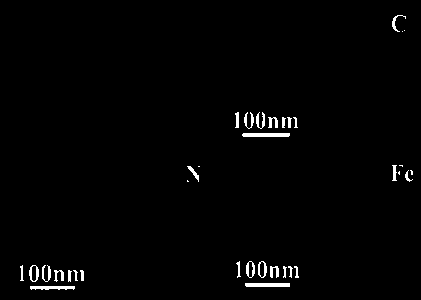

[0041] A preparation method based on iodine-doped graphene-wrapped hierarchical hole Prussian blue nanospheres, comprising the following steps:

[0042] (1) put K 3 [Fe(CN) 6 ] (0.1g) was dissolved in deionized water, added surfactant PVP (3.0g), ultrasonically stirred to clear liquid, then added 0.5 M HCl solution, after stirring for 60 min, a light yellow solution was formed and transferred to a 100 mL flask . Then put it into a water bath and raise the temperature to 80° C. under magnetic stirring, react for 24 hours, and then cool down to room temperature. The precipitate was collected by centrifugation, washed several times with distilled water and ethanol, and dried under vacuum at 60 °C for 12 h to obtain solid FeFe(CN) 6 Nanosphere precursors.

[0043] (2) the solid FeFe(CN) prepared by step (1) 6 Nanosphere precursor (0.15g) and surfactant PVP (0.45g) were added to 1.0 M HCl solution, stirred evenly, placed in a sealed stainless steel autoclave, and heated to 115...

Embodiment 2

[0046] A preparation method based on iodine-doped graphene-wrapped hierarchical hole Prussian blue nanospheres, comprising the following steps:

[0047] (1) put K 3 [Fe(CN) 6 ] (0.1g) was dissolved in deionized water, added surfactant PVP (3.0g), ultrasonically stirred to clear liquid, then added 0.5 M HCl solution, after stirring for 60 min, a light yellow solution was formed and transferred to a 100 mL flask . Then put it into a water bath and raise the temperature to 80° C. under magnetic stirring, react for 24 hours, and then cool down to room temperature. The precipitate was collected by centrifugation, washed several times with distilled water and ethanol, and dried under vacuum at 60 °C for 12 h to obtain solid FeFe(CN) 6 Nanosphere precursors.

[0048] (2) the solid FeFe(CN) prepared by step (1) 6 Nanosphere precursor (0.15g) and surfactant PVP (0.45g) were added to 1.0 M HCl solution, stirred evenly, placed in a sealed stainless steel autoclave, and heated to 115...

Embodiment 3

[0051] A preparation method based on iodine-doped graphene-wrapped hierarchical hole Prussian blue nanospheres, comprising the following steps:

[0052] (1) put K 3 [Fe(CN) 6 ] (0.1g) was dissolved in deionized water, added surfactant PVP (3.0g), ultrasonically stirred to clear liquid, then added 0.5 M HCl solution, after stirring for 60 min, a light yellow solution was formed and transferred to a 100 mL flask . Then it was put into a water bath and heated to 70° C. under magnetic stirring, reacted for 22 hours, and then cooled to room temperature. The precipitate was collected by centrifugation, washed several times with distilled water and ethanol, and dried under vacuum at 50 °C for 10 h to obtain solid FeFe(CN) 6 Nanosphere precursors.

[0053] (2) the solid FeFe(CN) prepared by step (1) 6 Nanosphere precursor (0.15g) and surfactant PVP (0.60g) were added to 1.5 M HCl solution, stirred evenly, placed in a sealed stainless steel autoclave, and heated to 120°C at a rate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com