Extraction method of lithium in spodumene, adsorption material for extraction of lithium and preparation method thereof

A technology of adsorption materials and extraction methods, applied in chemical instruments and methods, other chemical processes, lithium carbonate;/acid carbonate, etc., can solve the problems of large acid-base consumption and poor extraction effect, and achieve Long service life, good extraction effect, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

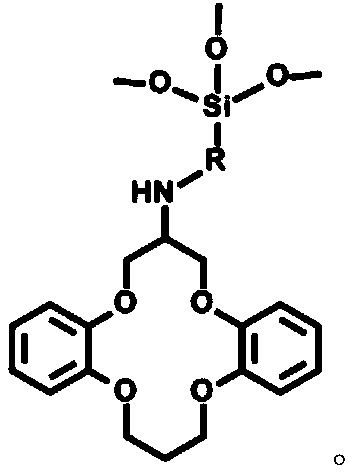

[0042] The preparation method of adsorption material of the present invention specifically comprises the following steps:

[0043] (1) React 1,3-dibromopropane, catechol and NaOH at a molar ratio of 1:(2-3):(2-3), preferably a molar ratio of 1:2:2. Specifically, first add 1,3-dibromopropane and catechol into the reaction flask, stir and heat up to 120-140°C, add NaOH aqueous solution within 1-2h and stir for 5-10h; Pour the liquid into 5N NaOH aqueous solution, add an appropriate amount of CH 2 Cl 2 , filter to remove solid impurities, adjust the filtrate to be neutral with HCl solution, and then use CH 2 Cl 2 Extraction, anhydrous Na 2 SO 4 Dry, remove the solvent with a rotary evaporator, and pass through the column with silica gel powder to obtain product A, and the structural formula of product A is as follows:

[0044]

[0045] (2) React the product A, LiOH and epichlorohydrin at a molar ratio of 1:(2-3):(1-2), preferably a molar ratio of 1:2:1. Specifically, un...

Embodiment 1

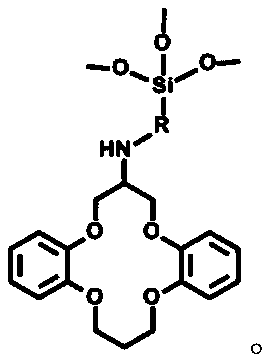

[0062] The preparation process of the adsorbent material of the present embodiment is as follows:

[0063] (1) React 1,3-dibromopropane, catechol and NaOH at a molar ratio of 1:2:2. Specifically, first add 1,3-dibromopropane and catechol into the reaction flask, stir and heat up to 120°C, add NaOH aqueous solution within 1h and stir for 5h; then pour the reaction mixture into 5N NaOH In the aqueous solution, add an appropriate amount of CH 2 Cl 2 , filter to remove solid impurities, adjust the filtrate to be neutral with HCl solution, and then use CH 2 Cl 2 Extraction, anhydrous Na 2 SO 4 Dry, remove the solvent with a rotary evaporator, and pass through a column with silica gel powder to obtain product A.

[0064] (2) The product A, LiOH and epichlorohydrin were reacted in a molar ratio of 1:2:1. Specifically, under the protection of nitrogen, the product A, LiOH, H 2 Add O into the reaction flask, heat up to 90°C and stir until completely dissolved; cool down to 40°C...

Embodiment 2

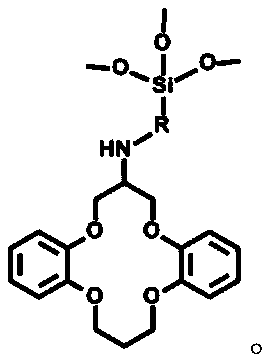

[0074] The preparation process of the adsorbent material of the present embodiment is as follows:

[0075] (1) 1,3-dibromopropane, catechol and NaOH were reacted at a molar ratio of 1:2.5:2.5. Specifically, first add 1,3-dibromopropane and catechol into the reaction flask, stir and heat up to 125°C, add NaOH aqueous solution within 1.5h and stir for 6h; then pour the reaction mixture into 5N NaOH aqueous solution, adding an appropriate amount of CH 2 Cl 2 , filter to remove solid impurities, adjust the filtrate to be neutral with HCl, then use CH 2 Cl 2 Extraction, anhydrous Na 2 SO 4 Dry, remove the solvent with a rotary evaporator, and pass through a column with silica gel powder to obtain product A.

[0076] (2) The product A, LiOH and epichlorohydrin were reacted in a molar ratio of 1:2.5:1.5. Specifically, under the protection of nitrogen, the product A, LiOH, H 2 Add O into the reaction flask, heat up to 92°C and stir until completely dissolved; drop the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com