Sewage treatment device, multistage sewage treatment equipment, sewage treatment system and sewage treatment method

A sewage treatment device and overflow technology, applied in water/sewage treatment equipment, water/sewage treatment, light water/sewage treatment, etc., to achieve compact structure, improve hydraulic load resistance, and avoid recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0158] The sewage treated in this embodiment is phenol-containing wastewater, and the water quality is as follows: COD is 120 mg / L, and pH is 6.50.

[0159] The phenol-containing wastewater to be treated is mixed with medicament (hydrogen peroxide, the consumption is 1mM in the buffer pool, i.e. H 2 o 2 Relative to the concentration of the whole sewage to be treated is 1mM, the same below), after being stirred evenly, it enters the sewage treatment device at a speed of 50mL / min, and is first filtered through a ceramic membrane tube, and the transmembrane pressure difference is 0.2MPa, and concentrated water is obtained in the filtration area. The water passing through the membrane tube is catalyzed by ultraviolet light, and effluent is obtained in the ultraviolet photocatalysis area, the lower buffer zone and the upper buffer zone; the flow rate of the concentrated water is controlled to 30mL / min, and the flow rate of the effluent is 20mL / min.

[0160] After the system was ru...

Embodiment 2

[0162] The sewage treated in this embodiment is MDEA wastewater, and the water quality is as follows: COD is 127mg / L, and pH is 7.50.

[0163] The MDEA wastewater to be treated is stirred evenly with the agent (hydrogen peroxide, dosage: 1mM) in the buffer tank and then enters the sewage treatment device at a speed of 50mL / min. Concentrated water is obtained, the water passing through the membrane tube is catalyzed by ultraviolet light, and effluent is obtained in the ultraviolet photocatalytic zone, lower buffer zone and upper buffer zone. The flow rate of concentrated water is controlled to 30mL / min, and the flow rate of effluent is 20mL / min.

[0164] After the system was running for 60 minutes, the water quality of the effluent was measured as follows: COD was 42.0 mg / L and pH was 5.12.

Embodiment 3

[0166] Process MDEA wastewater according to the method of Example 2, the difference is that the MDEA wastewater to be treated is stirred evenly with the medicament in the buffer tank and then enters the sewage treatment plant at a speed of 100mL / min, and the transmembrane pressure difference is adjusted to be 0.3MPa. Control the concentrated water flow rate to 60mL / min, and the effluent flow rate to 40mL / min.

[0167] After the system was running for 60 minutes, the water quality of the effluent was measured as follows: COD was 62.0 mg / L and pH was 5.89.

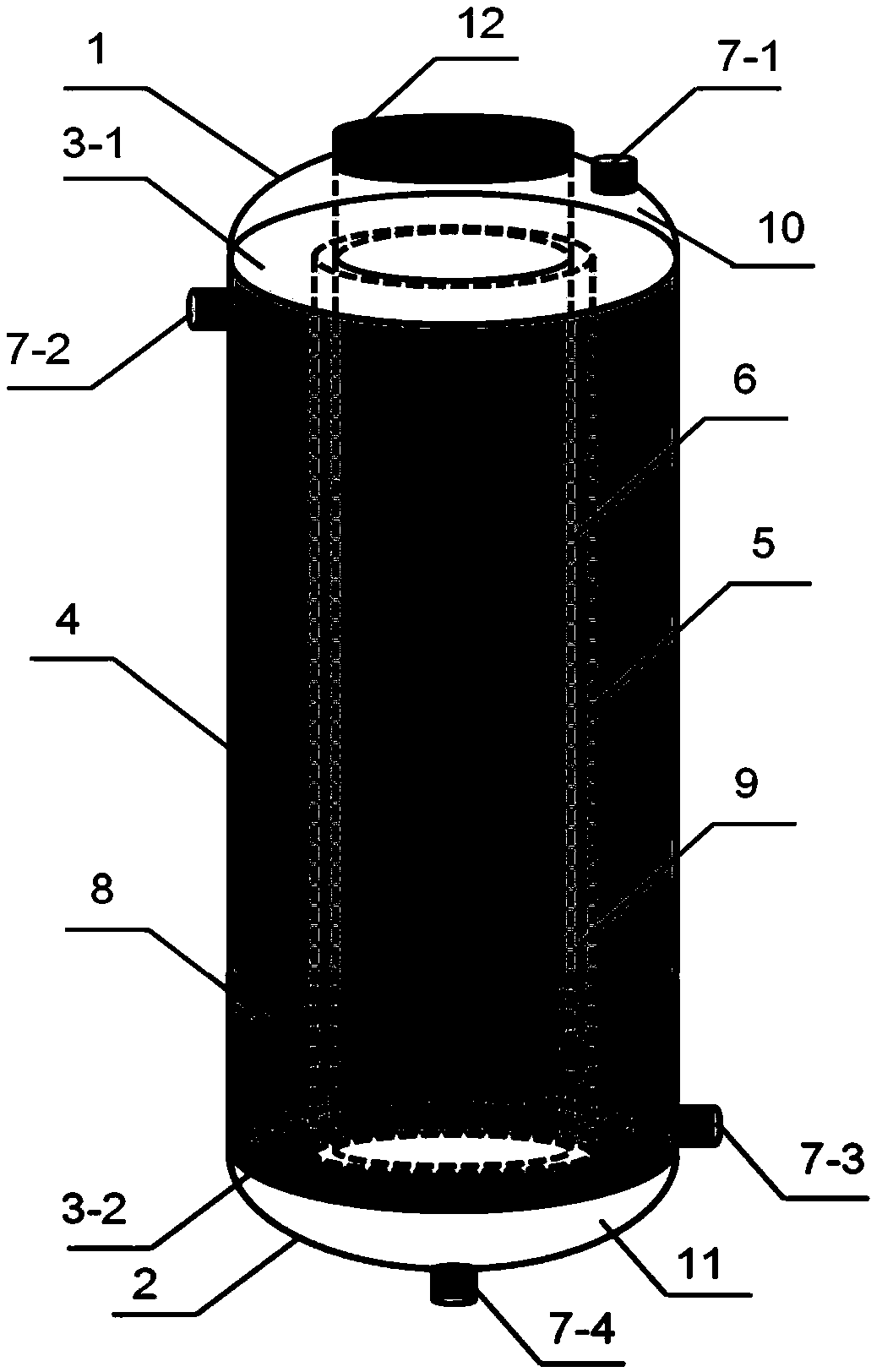

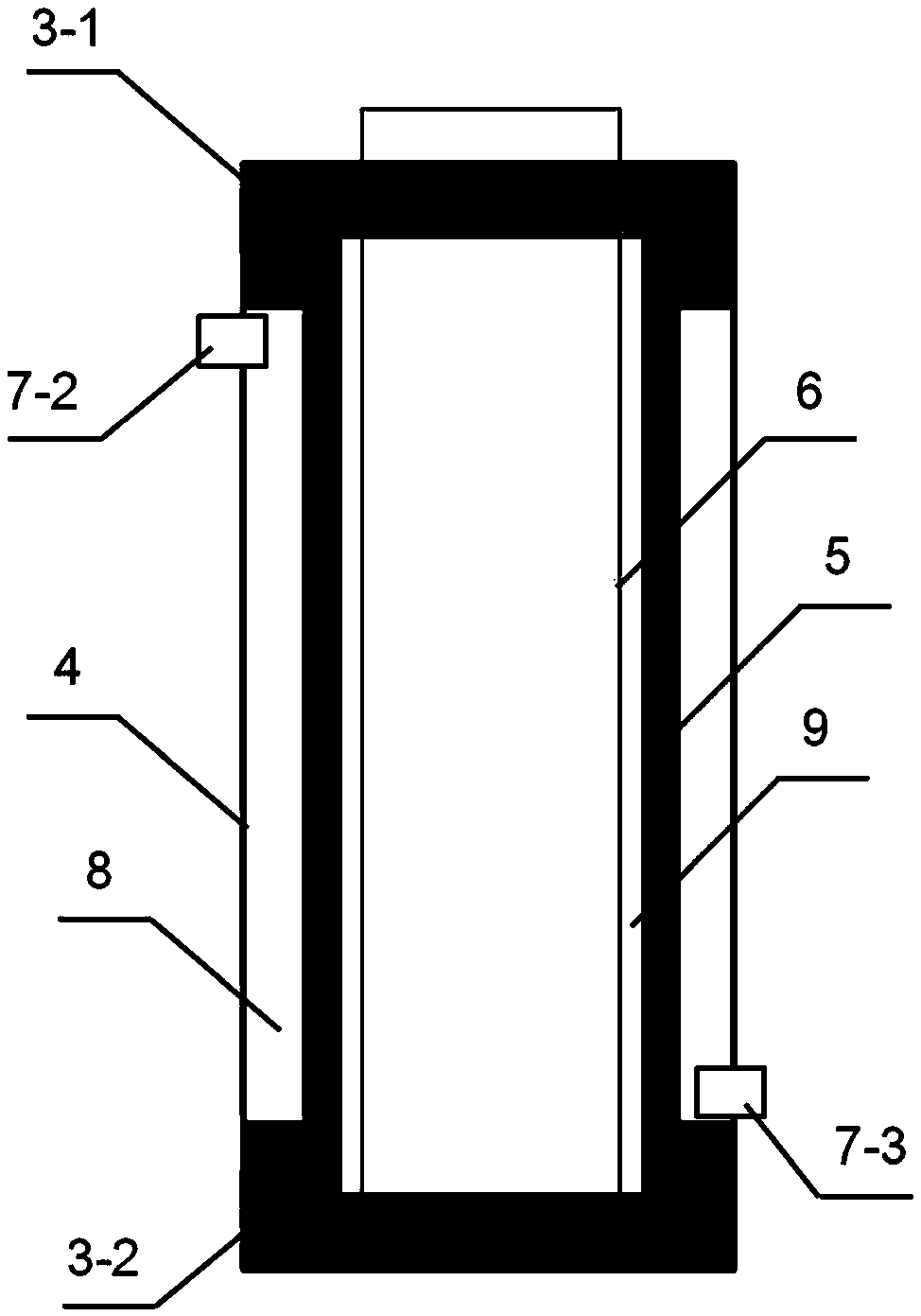

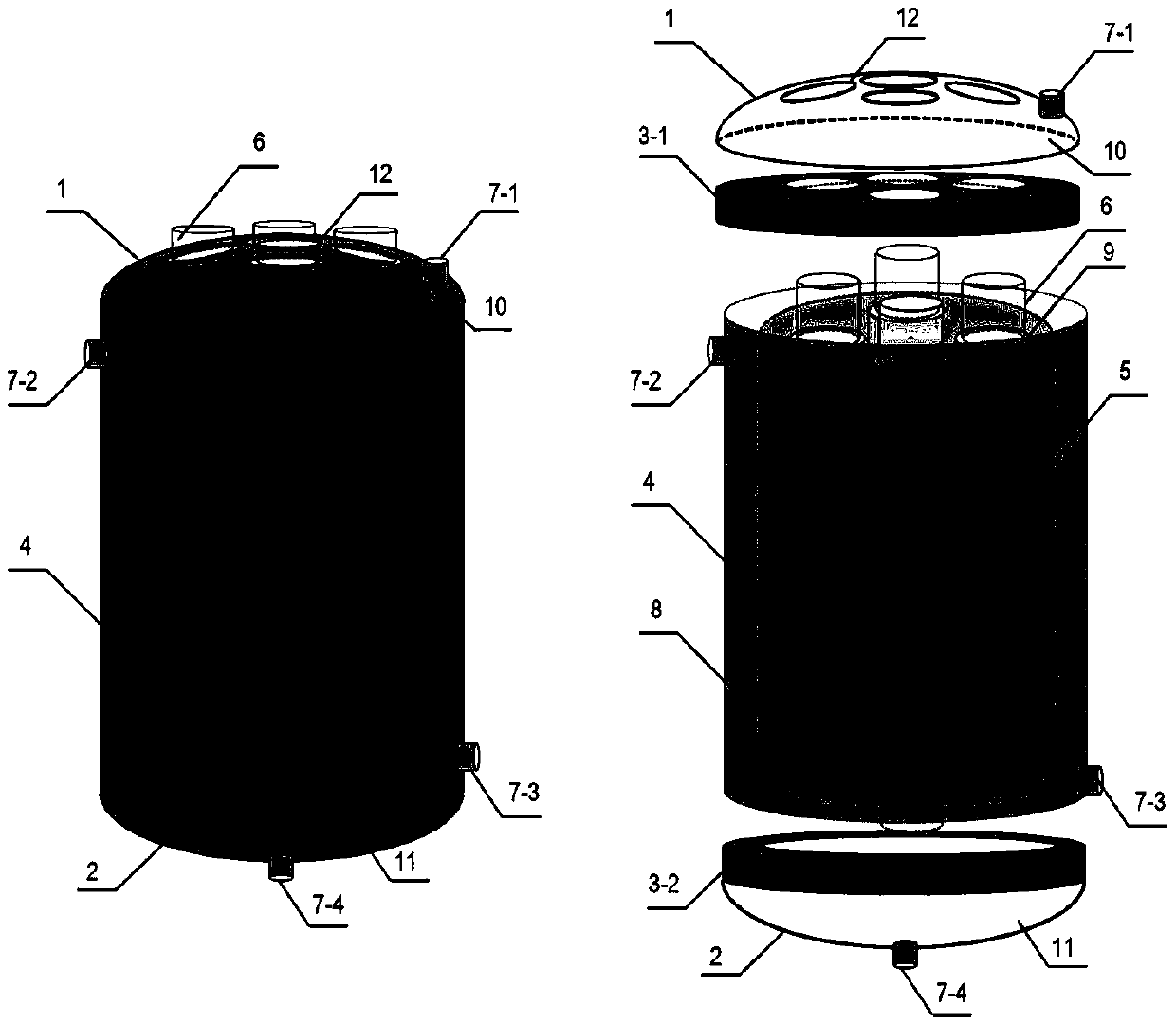

[0168] Embodiment 4-5 adopts Figure 6 Described sewage treatment system treats sewage, adopts such as image 3 and Figure 4 The sewage treatment plant shown.

[0169] In the sewage treatment device, the height of the hollow cylinder is 220mm, and the inner diameter is 130mm;

[0170] The number of channels of the multi-channel ceramic membrane tube is 4, and each group of two is arranged radially along the membrane tub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com