Preparation method of perovskite light emitting diode capable of improving performance

A perovskite and high-performance technology, which is applied in the field of perovskite light-emitting diode preparation, can solve the problems of limited solubility of inorganic perovskite light-emitting layer, discontinuous perovskite light-emitting layer, easy crystallization of thin film, etc. Effects of internal defects and device leakage current, improvement of performance and stability, and improvement of film coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

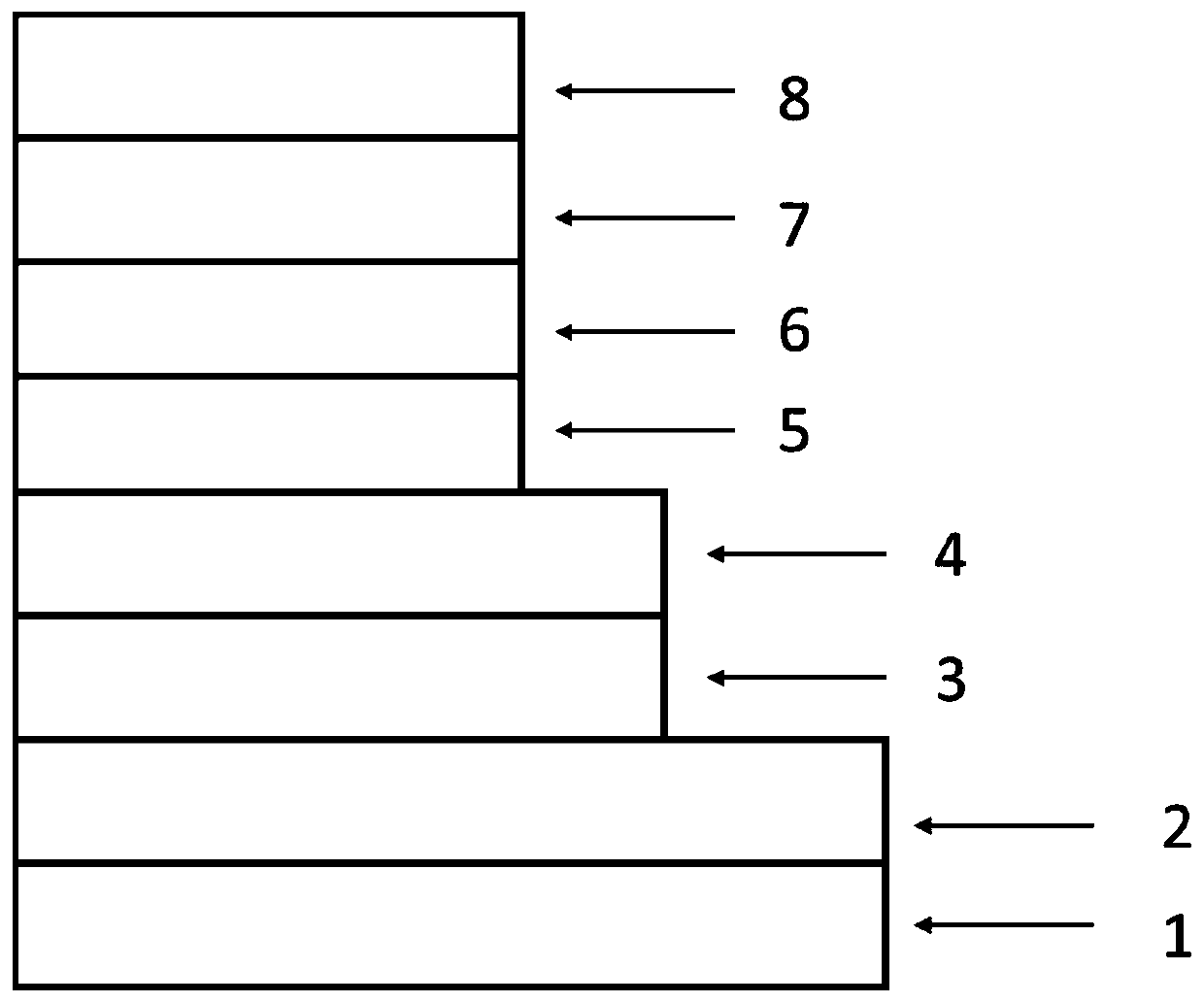

[0041] A method for preparing a perovskite light-emitting diode that can improve performance, comprising the following steps:

[0042] Step 1), preparing an anode interface layer 3 on a substrate 1 with a patterned transparent anode layer 2;

[0043] Step 2), preparing an anode interface modification layer 4 on the substrate of the anode interface layer 3;

[0044] Step 3), growing a perovskite light-emitting layer 5 on the anode modification layer 4;

[0045] Step 4), evaporating above the perovskite light-emitting layer 5 to obtain a cathode interface layer 6 , a cathode interface modification layer 7 and a cathode layer 8 .

[0046] Specifically:

[0047]1) Place the cleaned substrate 1 with a patterned transparent anode layer 2 with a thickness of 50-200 nanometers on the bracket of a spin coater, and evenly coat the entire sheet with PEDOT:PSS through a 0.45 micron filter head, By adjusting the rotation speed of the spin coater to 1000-5000 rpm, PEDOT:PSS forms a 10-50...

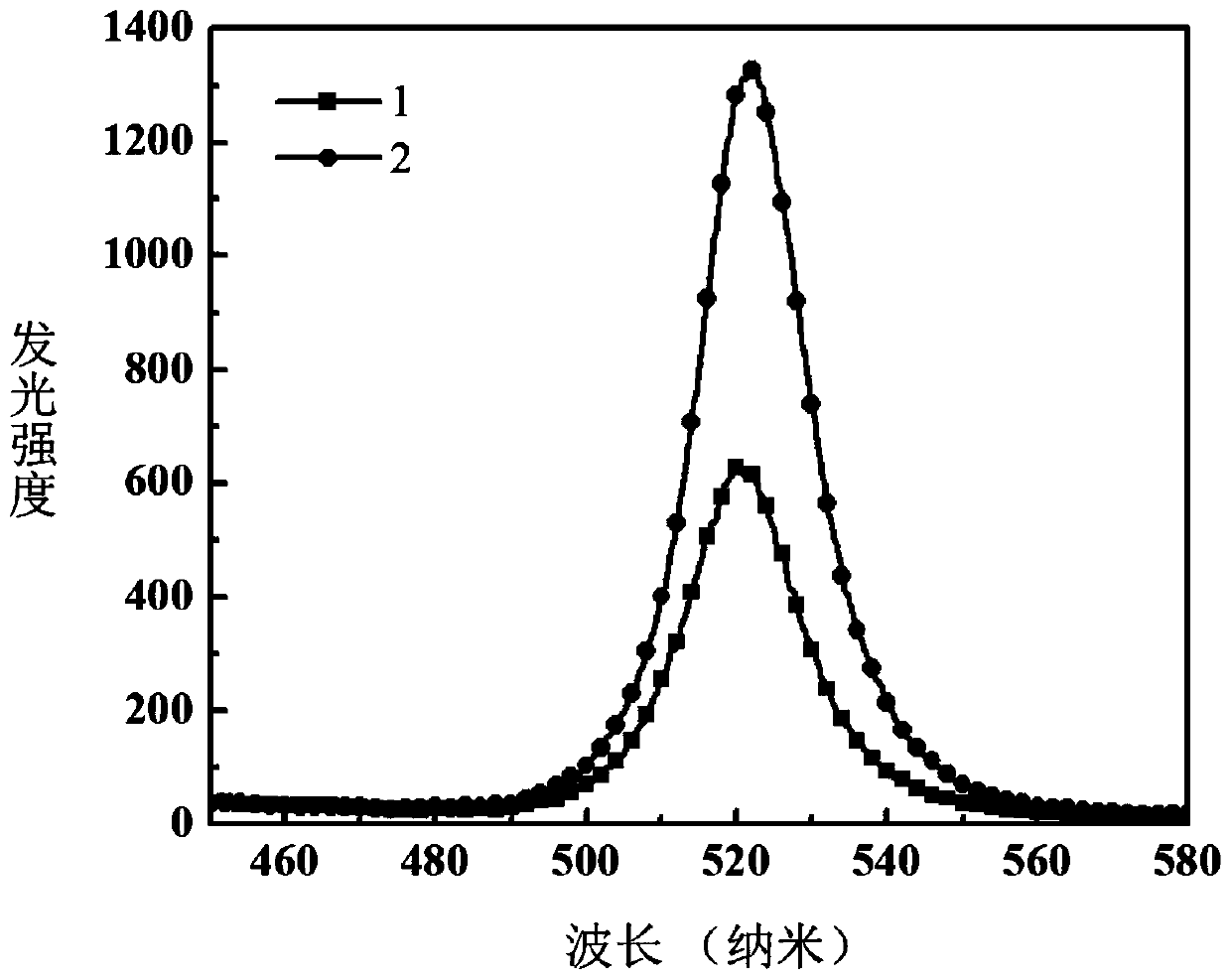

Embodiment 1

[0080] The preparation method of the perovskite light-emitting diode of the present embodiment comprises the following steps:

[0081] 1) Place the cleaned glass substrate with a patterned transparent anode ITO with a thickness of 120 nanometers on the bracket of the spin coater, pass through a 0.45 micron filter head, evenly coat the entire sheet with PEDOT:PSS, and adjust the spin coating The rotation speed of the coating machine is 2500 revolutions per minute, so that PEDOT:PSS forms a 30-nm-thick anode interface layer on the surface of the transparent electrode, and heats it in an oven at 120°C for 30 minutes;

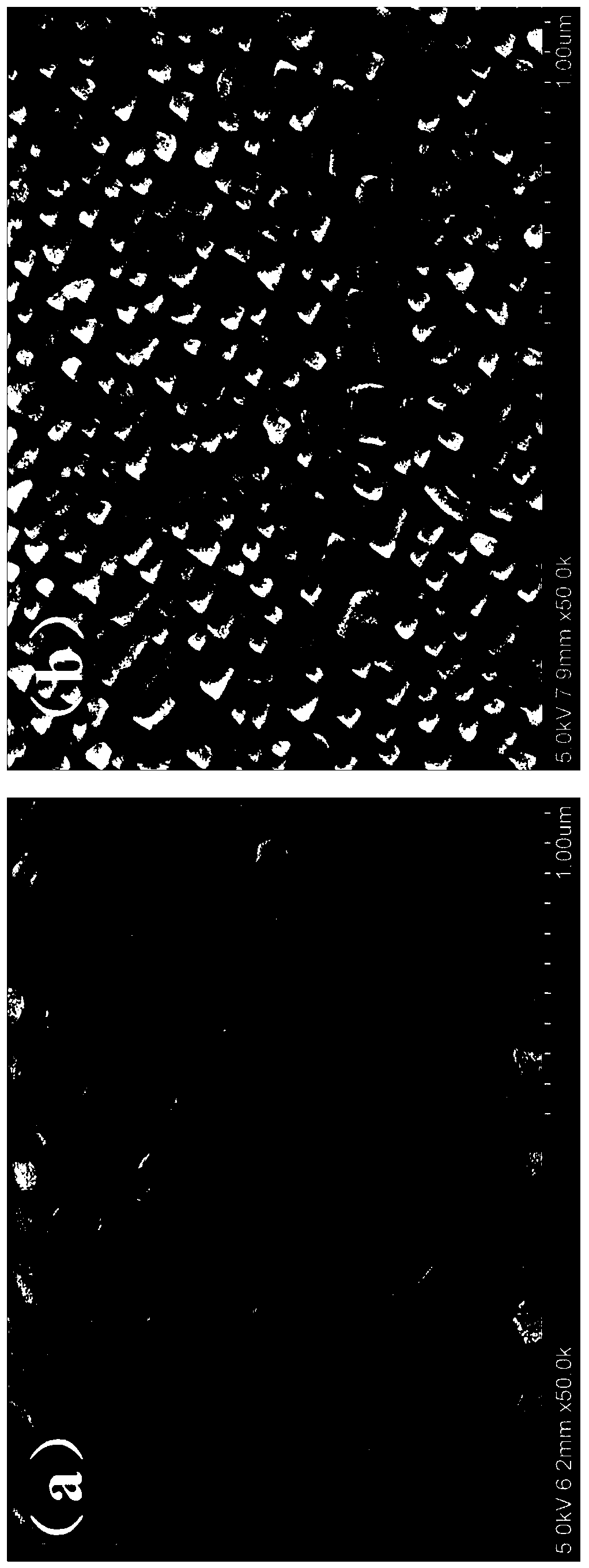

[0082] 2) Place the transparent anode substrate coated with PEDOT:PSS on the bracket of the spin coater after cooling, and evenly coat the whole sheet with the ethanolamine solution. By adjusting the rotation speed of the spin coater to 2500 rpm, the transparent electrode A monomolecular anode interface modification layer is formed on the surface, and placed on a h...

Embodiment 2

[0088] The preparation method of the perovskite light-emitting diode of the present embodiment comprises the following steps:

[0089] 1) Place the cleaned glass substrate with a patterned transparent anode ITO with a thickness of 50 nanometers on the bracket of the spin coater, and apply PEDOT:PSS evenly to the entire sheet through a 0.45 micron filter head. The rotation speed of the coating machine is 1000 revolutions per minute, so that PEDOT:PSS forms a layer of 50 nm thick anode interface layer on the surface of the transparent electrode, and heats it in an oven at 120°C for 30 minutes;

[0090]2) Place the above-mentioned transparent anode substrate coated with PEDOT:PSS on the bracket of the spin coater after cooling, and evenly coat the whole sheet with the isopropanolamine solution, and adjust the rotation speed of the spin coater to 5000 revolutions per minute. A monomolecular anode interface modification layer is formed on the surface of the transparent electrode, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com