Simultaneously improve the flux and anti-pollution performance of polyamide reverse osmosis composite membrane

A technology of reverse osmosis composite membrane and polyamide, which is applied in the direction of semi-permeable membrane separation, chemical instruments and methods, membranes, etc., can solve the problem of rough surface of polyamide reverse osmosis composite membrane, large mass transfer resistance of water molecules, high membrane material Improve the permeability and anti-pollution performance, increase the chemical potential, and avoid membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] S1, dissolve 1.5g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 15g triethanolamine and 10g sodium phosphate in 1000ml pure water, and use 0.1mol / l Adjust pH to 7.0 with HCl solution or NaOH solution as modified solution A;

[0034] S2, take 100g 1,4-butane sultone and dissolve it in 1000ml ethanol / water solution (volume ratio is 1:1), stir it evenly and use it as modified solution B;

[0035] S3. Rinse the commercial polyamide reverse osmosis composite membrane with pure water, soak it in the modified solution A, take it out after 5 hours and wash it with pure water;

[0036] S4. After contacting the above-mentioned S3 membrane sheet with the modification solution B for 15 hours, remove the excess solution, and wash it with pure water for use.

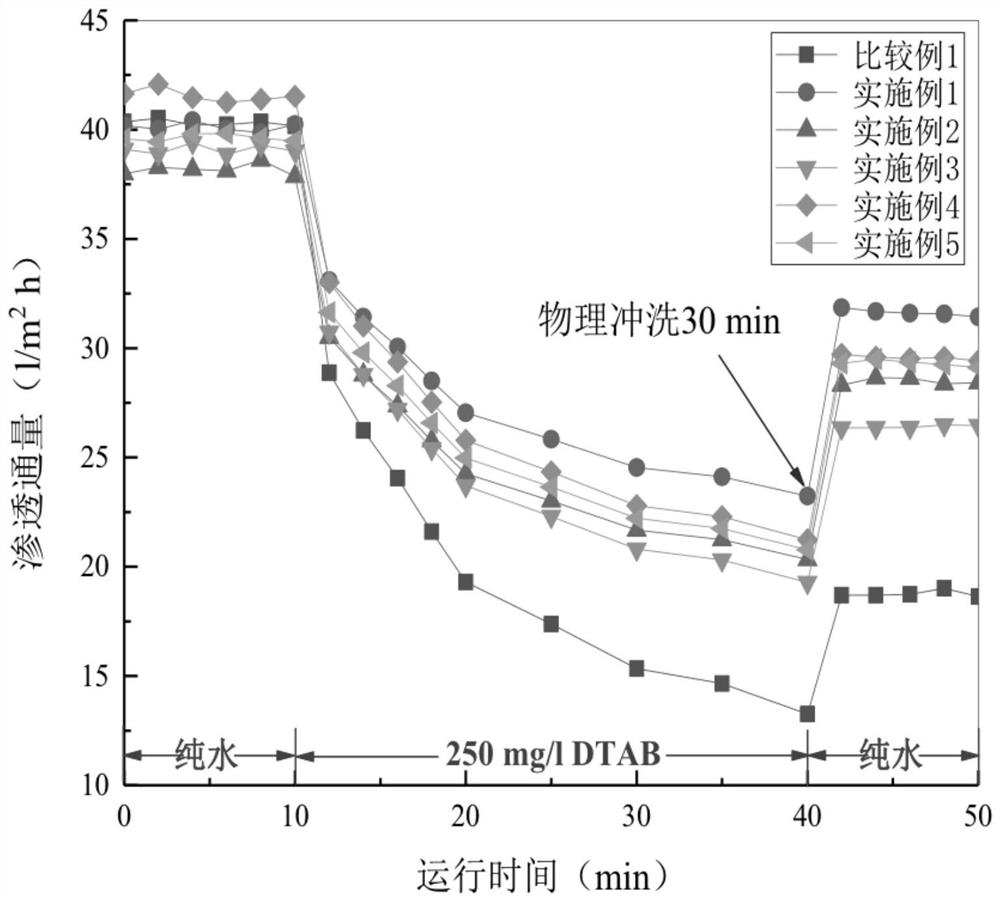

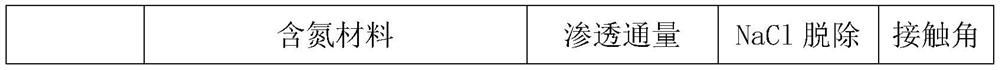

[0037] The salt rejection and water flux of the polyamide reverse osmosis composite membrane were tested under the conditions of NaCl concentration of 2000 mg / l, pressure of 1.55 MPa, temperature of 25 °C, and pH ...

Embodiment 2

[0041] S1, take 1.5g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 15g 1-(2-hydroxyethyl) piperazine and 10g sodium phosphate and dissolve in 1000ml pure water , and use 0.1mol / l HCl solution or NaOH solution to adjust pH to 7.0 as modified solution A;

[0042] S2, take 100g 1,4-butane sultone and dissolve it in 1000ml ethanol / water solution (volume ratio is 1:1), stir it evenly and use it as modified solution B;

[0043] S3. Rinse the commercial polyamide reverse osmosis composite membrane with pure water, soak it in the modified solution A, take it out after 5 hours and wash it with pure water;

[0044] S4. After contacting the above-mentioned S3 membrane sheet with the modification solution B for 15 hours, remove the excess solution, and wash it with pure water for use.

[0045] The salt rejection and water flux of the polyamide reverse osmosis composite membrane were tested under the conditions of NaCl concentration of 2000 mg / l, pressure of 1.55 MPa, tempe...

Embodiment 3

[0049] S1, dissolve 1.5g 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride, 15g N-methylpiperazine and 10g sodium phosphate in 1000ml pure water, and use 0.1 mol / l HCl solution or NaOH solution to adjust pH to 7.0 as modified solution A;

[0050] S2, take 100g 1,4-butane sultone and dissolve it in 1000ml ethanol / water solution (volume ratio is 1:1), stir it evenly and use it as modified solution B;

[0051] S3. Rinse the commercial polyamide reverse osmosis composite membrane with pure water, soak it in the modified solution A, take it out after 5 hours and wash it with pure water;

[0052] S4. After contacting the above-mentioned S3 membrane sheet with the modification solution B for 15 hours, remove the excess solution, and wash it with pure water for use.

[0053] The salt rejection and water flux of the polyamide reverse osmosis composite membrane were tested under the conditions of NaCl concentration of 2000 mg / l, pressure of 1.55 MPa, temperature of 25 °C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com