Preparation method of acellular dermal matrix material

An acellular dermis and matrix material technology, which is applied in the field of the preparation of acellular dermal matrix materials, can solve the problems of dermal matrix structural damage, poor material mechanical strength, insufficient thermal stability, etc., and achieves the promotion of cell growth and reproduction, and the improvement of stability. effect on cell adhesion and nutrient exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The present invention will be further described below in conjunction with accompanying drawings and Examples, and the protection scope of the present invention is not limited to the following: Embodiment 1: Preparation of decellularized dermal matrix material

[0018] A preparation method of decellularized dermal matrix material, which comprises the following steps:

[0019] S1. Peeling: take the discarded pigskin, scrape off the hair on the surface, cut out the dermal matrix with a thickness of 0.1-3mm and contain the epidermis, and remove the fat tissue at the same time;

[0020] S2. Soaking: Soak the peeled dermal matrix in an acetaldehyde solution containing glycine for 1-2 hours, the mass percent concentration of glycine is 4-5%, and the ratio of the volume of the solution to the mass of the dermal matrix is 2:1;

[0021] S3. Decellularization: the soaked dermal matrix is placed in the eluent for elution, the solid-liquid ratio of the eluent to the dermal matri...

Embodiment 2

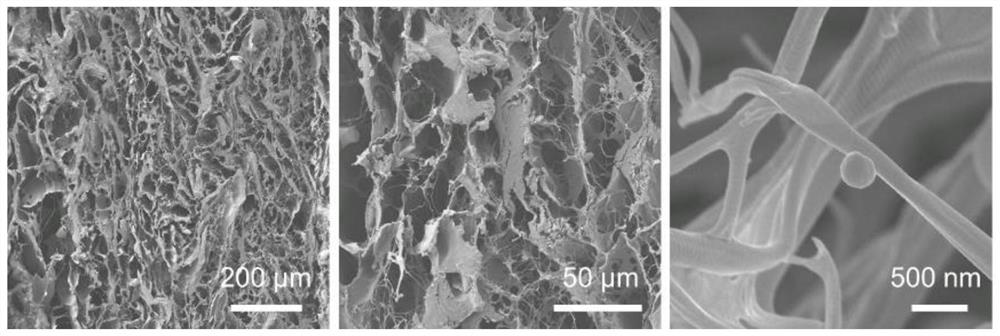

[0023] Embodiment 2: scanning electron microscope observation (SEM)

[0024] (1) Method: Cut the acellular dermal matrix material prepared in Example 1 into 5×5mm 2 Size, use tweezers to place the bracket sample on the stage with conductive glue, press it lightly and blow it with a dust blower to fix it; spray gold on the bracket sample; after the gold spray is completed, put the stage with the sample into in a scanning electron microscope. The structure of the sample was observed with a voltage of 5.0KeV and a current of 10mA.

[0025] (2) Results: results such as figure 1 As shown, by SEM observation, the porcine acellular dermal matrix material has a honeycomb porous network structure inside after being freeze-dried by a freeze dryer, the connectivity between the pores is good, and the fibers in the matrix are clustered, indicating that the material is The collagen fiber structure is not damaged during the preparation process and is well preserved. This porous structure ...

Embodiment 3

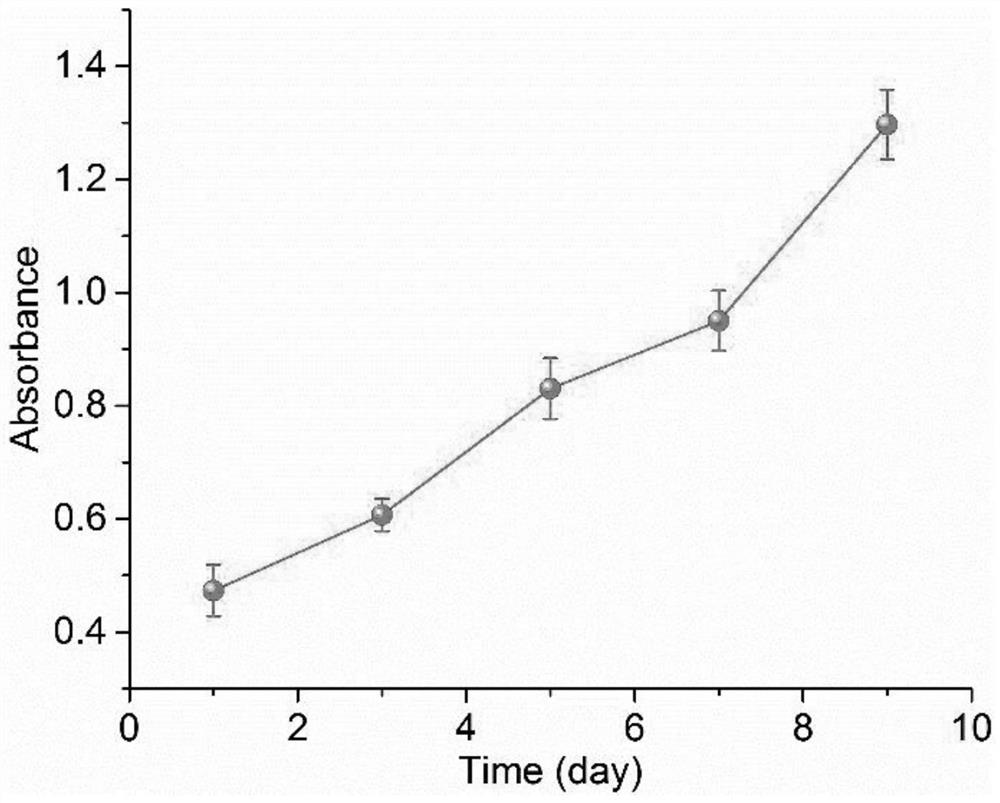

[0026] Embodiment 3: cell proliferation experiment:

[0027] (1) Method: The porcine acellular dermal matrix material prepared in Example 1 was cut into small pieces and put into 24-well plates. The samples were immersed in the culture medium for 2h. Trypsinize L929 cells with 0.25% trypsin in a culture flask, and prepare cell suspension at a concentration of 1×10 5 / mL. Carefully aspirate a 100 µL aliquot of the cell suspension and add it evenly to the surface of the sample, then place in a constant temperature incubator for 4 h. Subsequently, 900 μL of medium was added to each well to continue culturing, and the DMEM medium was replaced every 3 days. Cultures were aspirated on days 1, 3, 5, 7 and 9. Add the same amount of fresh DMEM medium, followed by 50 μL of CCK-8 reagent to each well, and place in 37 °C CO 2 Shake slowly for another 4 h in the incubator. Take a 200 µL aliquot from each well and transfer to a 96-well plate. Read the absorbance at 450 nm with a micr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com