A kind of tungsten oxide homojunction composite photocatalyst and its preparation method and application

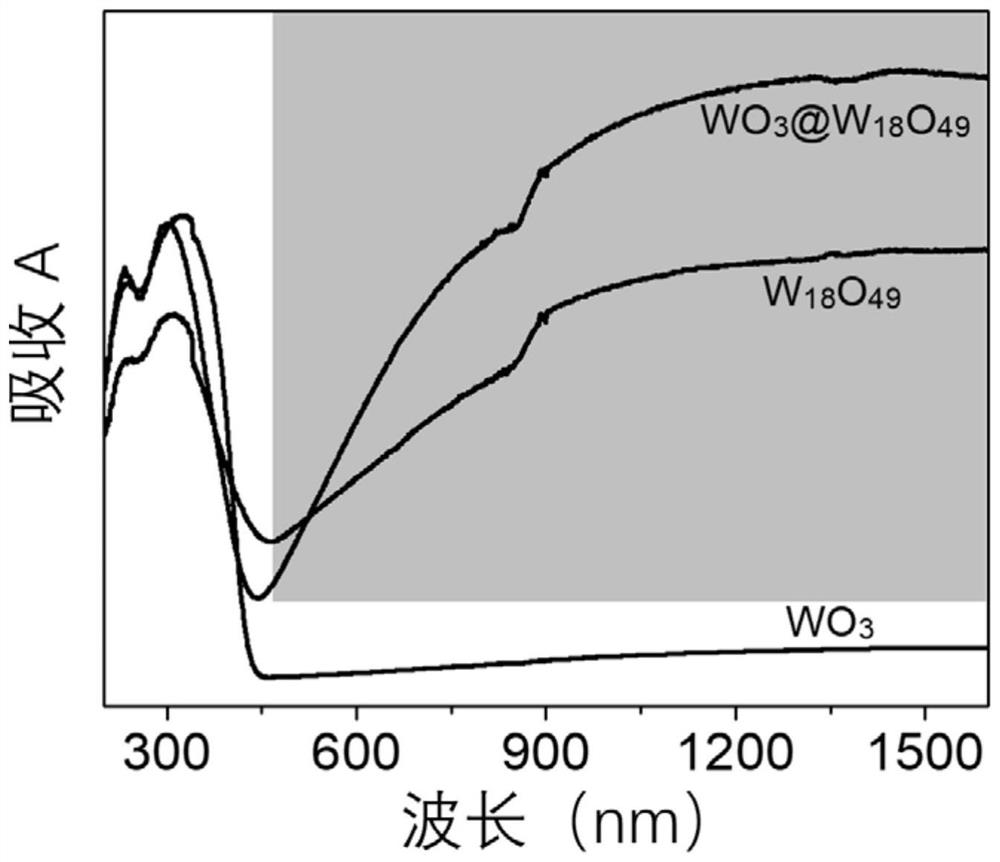

A technology of tungsten oxide and composite light, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, etc. Problems such as high hole recombination rate and hindrance to interface charge separation can achieve the effects of industrial application, large photoresponse range, and improved photocatalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

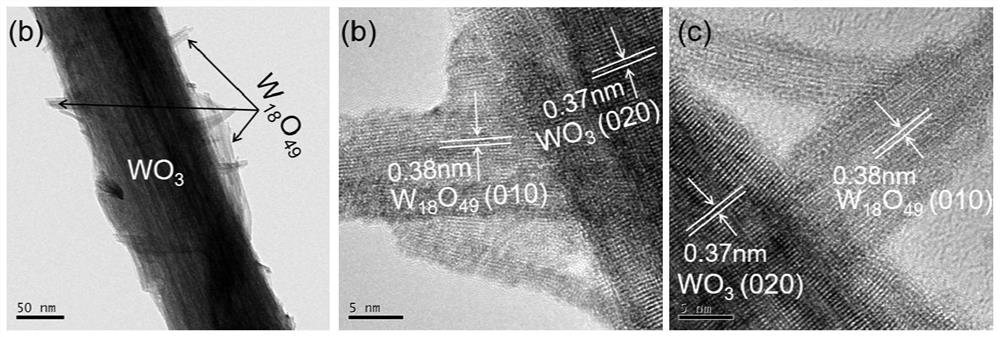

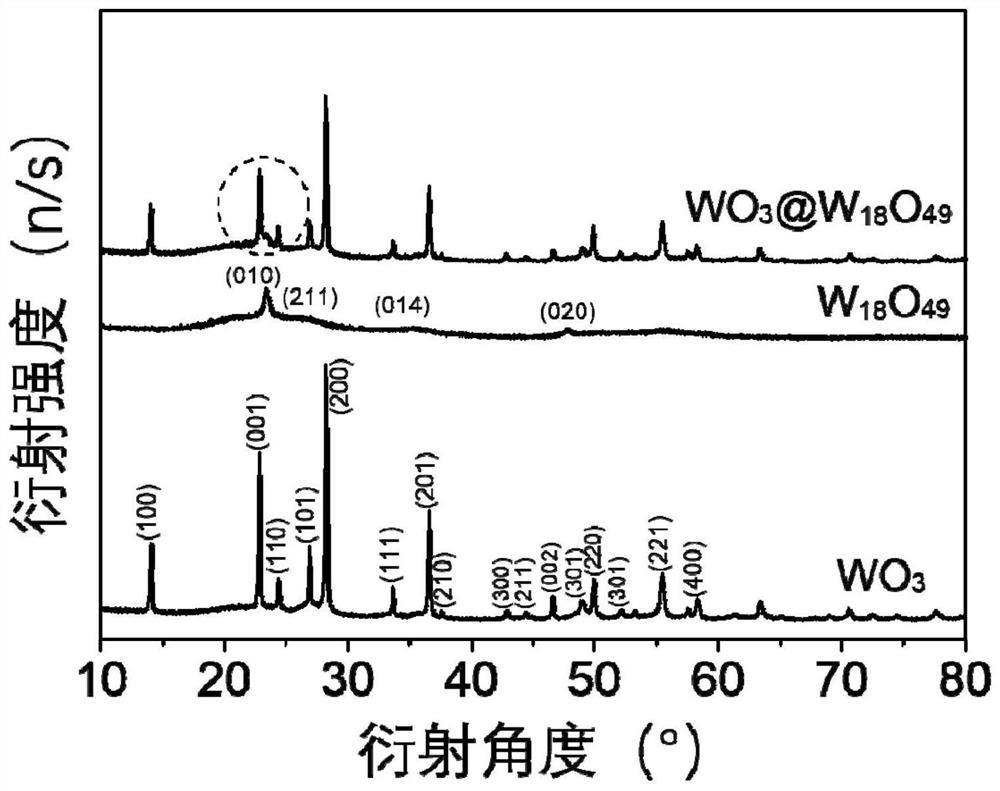

[0036] A kind of tungsten oxide homojunction composite photocatalyst, with tungsten oxide (WO 3 ) nanorods as the carrier, and non-stoichiometric tungsten oxide (W 18 o 49 ) nano branch.

[0037] In this embodiment, the mass ratio of tungsten oxide nanorods to non-stoichiometric tungsten oxide branches is 5:4.

[0038] In this embodiment, the diameter of the tungsten oxide nanorods in the tungsten oxide homojunction composite photocatalyst is 200 nm; the non-stoichiometric tungsten oxide nano-branches are fibrous, and the diameter of the non-stoichiometric tungsten oxide nano-branches is 5 nm.

[0039] In this embodiment, non-stoichiometric tungsten oxide nanobranches are grown on the surface of tungsten oxide nanorods by solvothermal in-situ epitaxial growth to form a tungsten oxide homojunction composite photocatalyst.

[0040] A method for preparing the tungsten oxide homojunction composite photocatalyst in the above-mentioned present embodiment, comprising the following s...

Embodiment 2

[0051] An application of a tungsten oxide homojunction composite photocatalyst in the treatment of organic wastewater, specifically using a tungsten oxide homojunction composite photocatalyst to treat 2,4-dichlorophenol wastewater, comprising the following steps:

[0052] Take respectively the tungsten oxide homojunction composite photocatalyst (WO) that 0.5g embodiment 1 makes 3 @W 18 o 49 ), tungsten oxide nanorods (WO 3 ) 2,4-dichlorophenol wastewater, added to 50mL of 2,4-dichlorophenol wastewater with an initial concentration of 20mg / L under light-shielding conditions, stirred for 30min, and the mixture was placed in a photocatalytic In the reaction device, a 300W xenon lamp was used as the light source to carry out photocatalytic reaction for 60 minutes to complete the treatment of 2,4-dichlorophenol wastewater.

[0053] During the photocatalytic reaction, samples were taken every 10 minutes, the samples were centrifuged, the supernatant was taken, and the concentrati...

Embodiment 3

[0059] Investigate the stability of the tungsten oxide homojunction composite photocatalyst of the present invention, comprise the following steps:

[0060] (1) Centrifuge the remaining reaction solution after the photocatalytic reaction in Example 2, collect the tungsten oxide homojunction composite photocatalyst, wash it three times with deionized water and absolute ethanol, and then place it in a 60°C oven to dry 12h.

[0061] (2) Adopt the same treatment method as in Example 2, repeatedly use the tungsten oxide homojunction composite photocatalyst obtained after drying in step (1) to treat 2,4-dichlorophenol wastewater, and repeat 5 times in total test.

[0062] Figure 6 It is a cyclic degradation effect diagram of 2,4-dichlorophenol by the tungsten oxide homojunction composite photocatalyst in Example 3 of the present invention. Depend on Figure 6 It can be seen that after 5 cycles of use, the removal rate of 2,4-dichlorophenol in the tungsten oxide homojunction com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com