Cobalt-iron bimetallic nitride composite electrocatalyst and preparation method and application thereof

An electrocatalyst and bimetallic technology, applied in the field of electrocatalysis, can solve the problems of complicated and time-consuming heating process, achieve the effect of increasing the specific surface area, good application prospects, and reducing the internal resistance of the electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

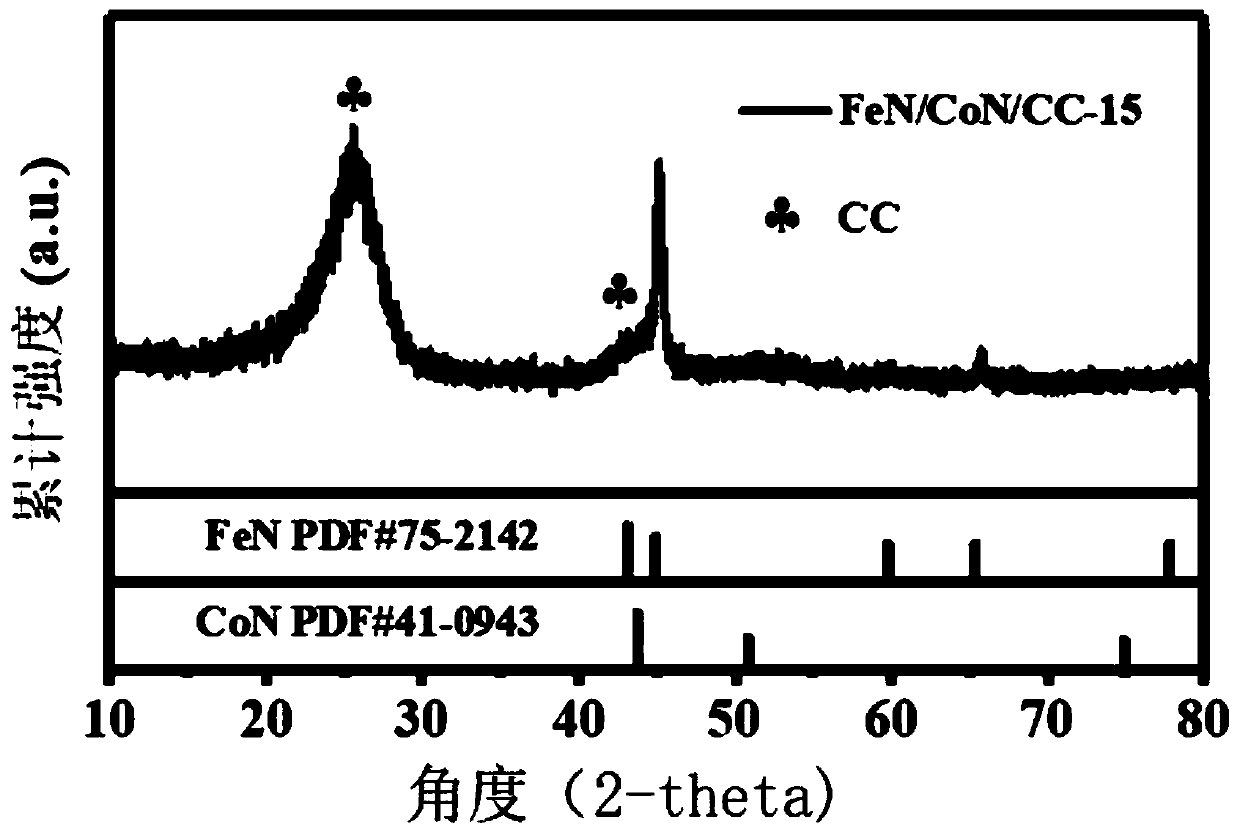

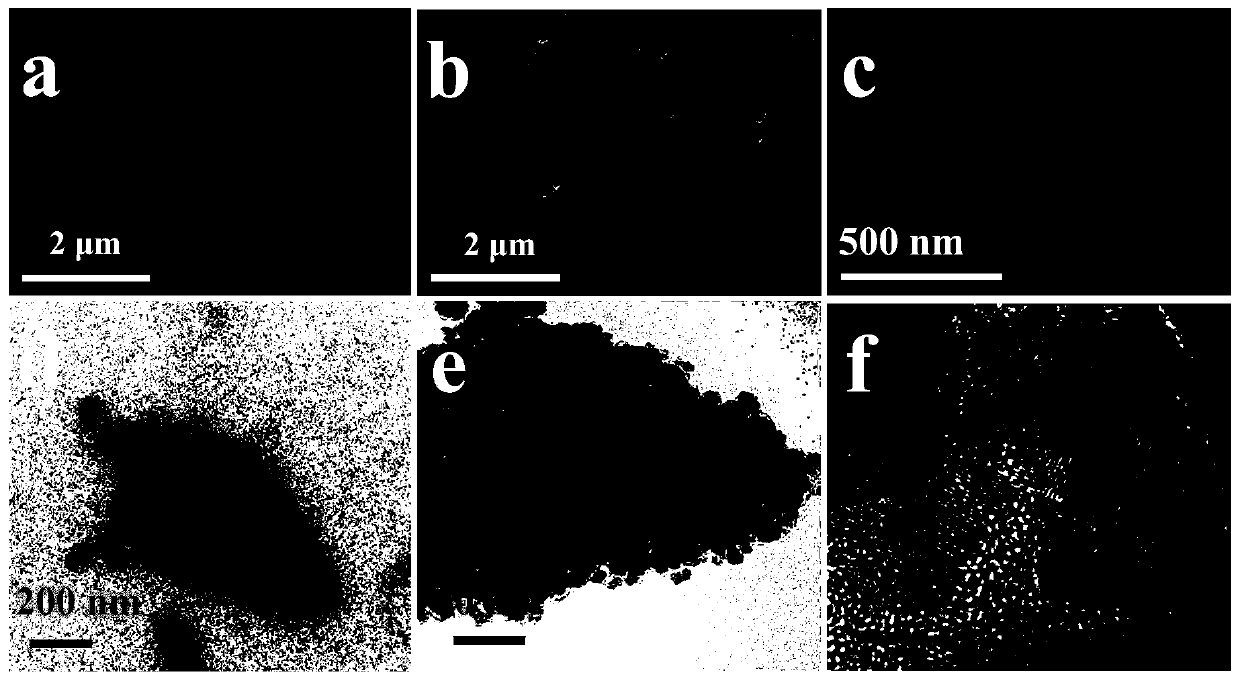

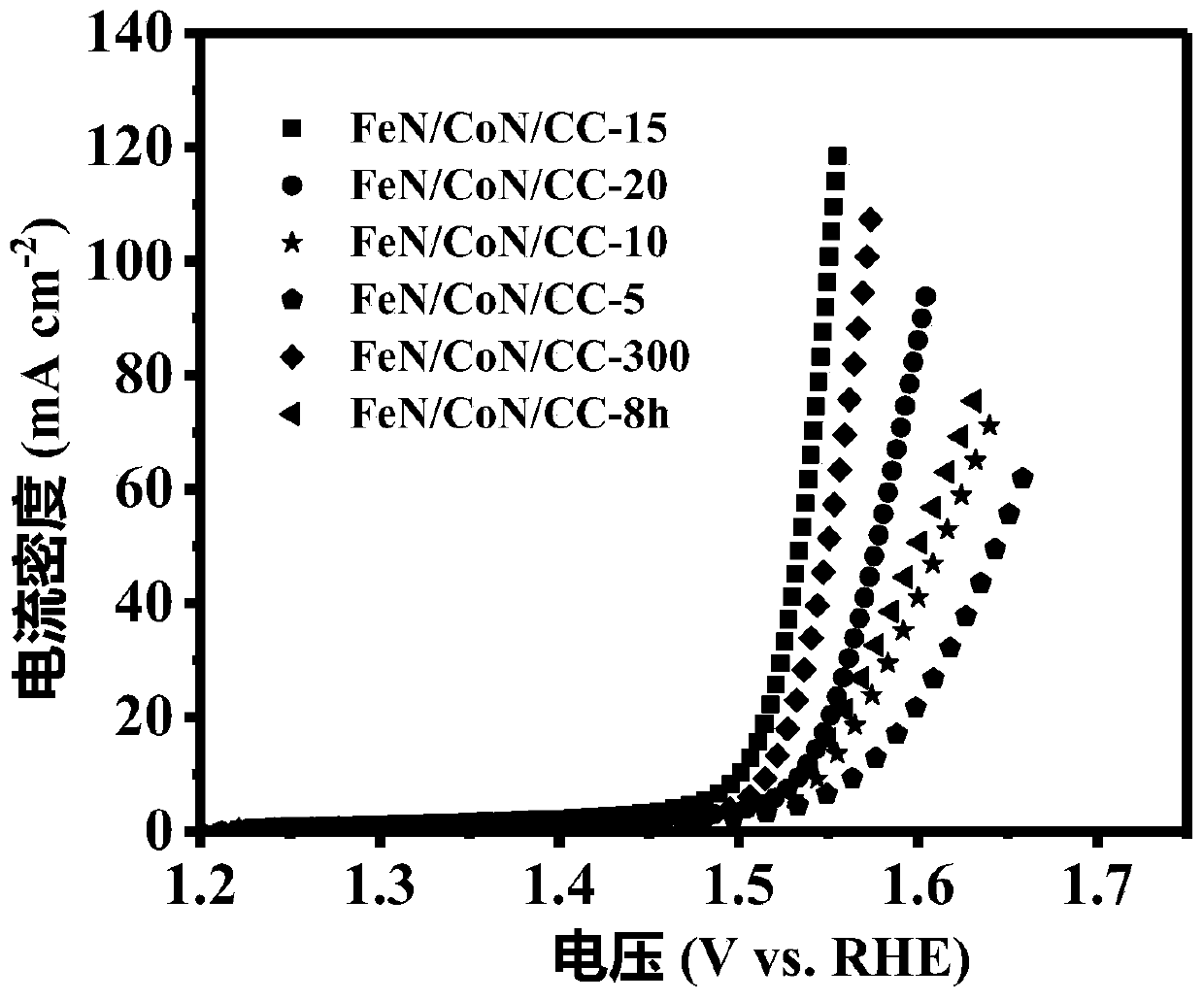

[0029] Embodiment 1, a kind of carbon cloth (CC) is the preparation of the cobalt-iron double metal nitride composite electrocatalyst (FeN / CoN / CC) of substrate, concrete steps are:

[0030] (1) The cut CC (2cm×5cm; thickness: 360μm; density: 120g / m 2 ) first use 16mol / L

[0031] Concentrated nitric acid was refluxed at 120°C for 12h, then ultrasonically cleaned with deionized water, acetone and ethanol in sequence, and then vacuum-dried (60°C, 12h) to obtain clean CC.

[0032] (2) Weigh 1.3136g of 2-methylimidazole, add 40mL of deionized water and stir until a clear solution is obtained to obtain 2-methylimidazole aqueous solution A; then weigh 0.5821g of cobalt nitrate, add 40mL of deionized water and stir until completely Dissolve to obtain the cobalt nitrate aqueous solution B, quickly add the B solution to the A solution, stir until the mixture is uniform, and obtain the mixed solution C. Add cleaned carbon cloth to the mixed solution C, and precipitate at room temperatu...

Embodiment 2

[0034] Embodiment 2, a kind of carbon cloth (CC) is the preparation of the cobalt-iron double metal nitride composite electrocatalyst (FeN / CoN / CC) of substrate, concrete steps are:

[0035] (1) The cut CC (2cm×5cm; thickness: 360μm; density: 120g / m 2) first refluxed with 16mol / L concentrated nitric acid at 120°C for 12h, then ultrasonically cleaned with deionized water, acetone and ethanol in sequence, and vacuum dried (60°C, 12h) to obtain clean CC.

[0036] (2) Weigh 1.3136g of 2-methylimidazole, add 40mL of deionized water and stir until a clear solution is obtained to obtain 2-methylimidazole aqueous solution A; then weigh 0.5821g of cobalt nitrate, add 40mL of deionized water and stir until completely Dissolve to obtain the cobalt nitrate aqueous solution B, quickly add the B solution to the A solution, stir until the mixture is uniform, and obtain the mixed solution C. Add cleaned carbon cloth to the mixed solution C, and precipitate at room temperature for 2 hours. Aft...

Embodiment 3

[0038] Embodiment 3, a kind of carbon cloth (CC) is the preparation of the cobalt-iron bimetallic nitride composite electrocatalyst (FeN / CoN / CC) of substrate, concrete steps are:

[0039] (1) The cut CC (2cm×5cm; thickness: 360μm; density: 120g / m 2 ) first refluxed with 16mol / L concentrated nitric acid at 120°C for 12h, then ultrasonically cleaned with deionized water, acetone and ethanol in sequence, and vacuum dried (60°C, 12h) to obtain clean CC.

[0040] (2) Weigh 1.3136g of 2-methylimidazole, add 40mL of deionized water and stir until a clear solution is obtained to obtain 2-methylimidazole aqueous solution A; then weigh 0.5821g of cobalt nitrate, add 40mL of deionized water and stir until completely Dissolve to obtain the cobalt nitrate aqueous solution B, quickly add the B solution to the A solution, stir until the mixture is uniform, and obtain the mixed solution C. Add cleaned carbon cloth to the mixed solution C, and precipitate at room temperature for 2 hours. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com