Polypyrrole-based photo-thermal conversion film and preparation method and application thereof

A polypyrrole-based light, photothermal conversion technology, applied in textiles and papermaking, coatings, paper coatings, etc., can solve the problem of polypyrrole difficulty and other problems, and achieve energy loss reduction, strong universality, and strong light absorption ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

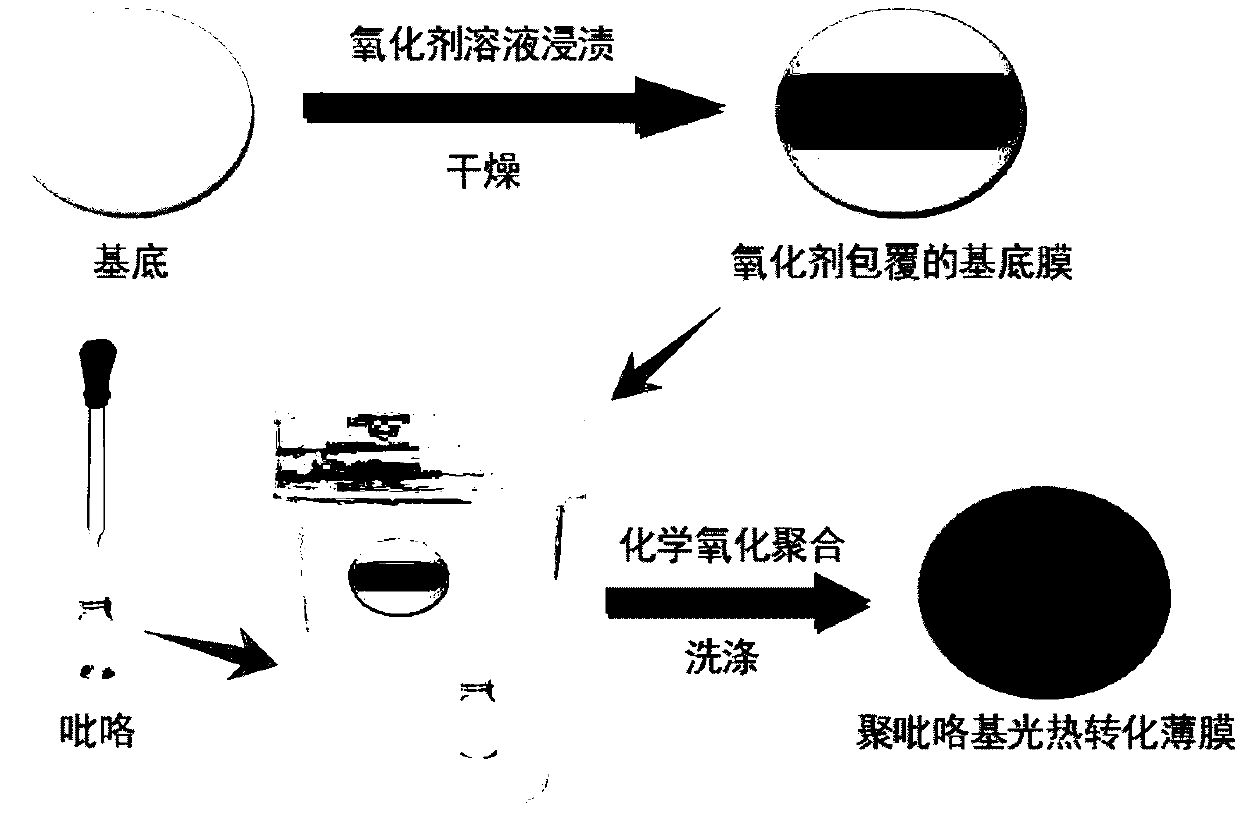

[0046] (1) Preparation of air-laid paper (AP) film coated with ferric chloride: Soak the air-laid paper with a diameter of 30mm in 0.1mol / L ferric chloride aqueous solution at room temperature for 6h , taken out and dried in an oven at 60°C to obtain a dust-free paper film coated with ferric chloride.

[0047](2) Preparation of polypyrrole (Polypyrrole, be called for short PPy) coated dust-free paper film: measure the pyrrole monomer of 10 μ l, drop in the open glass bottle, mix it with the ferric chloride that step (1) obtains The coated dust-free paper film was put into a closed polypropylene plastic bottle, and then the plastic bottle was moved into an oven at 80°C for polymerization reaction, and it was taken out after 0.5h to obtain a polypyrrole-coated dust-free paper film.

[0048] (3) Preparation of polypyrrole-based dust-free paper film: the polypyrrole-coated dust-free paper film obtained in step (2) was washed with ethanol several times, and dried in an oven at 60°C...

Embodiment 2

[0063] The difference from Example 1 is that according to the preparation method of Example 1, the polymerization reaction temperature in step 2) in the preparation of the polypyrrole (PPy)-coated dust-free paper film was adjusted to room temperature (25° C.).

[0064] Figure 9 It is the color change of the sample over a period of time during the preparation of PPy-AP by the CVD method at room temperature (25°C); Figure 9 It can be seen that the dust-free paper film coated with ferric chloride turns from yellow to black within a few minutes, indicating that the growth process of polypyrrole can be completed in a short time, and can be grown at a relatively low temperature. conduct. It can be seen that the method of the present invention is simple and efficient.

Embodiment 3

[0066] The difference from Example 1 is: according to the preparation method of Example 1, the size of the air-laid paper in the preparation of the air-laid paper (Air-laid paper, referred to as AP) film coated with ferric chloride in step 1) is adjusted It is 16cm long and 14cm wide.

[0067] Depend on Figure 10 It can be seen that by using the CVDP method, only 10 μl of pyrrole monomer is used to obtain a surface area of more than 200 cm without using any other valuable medicines or articles. 2 light-to-heat conversion film. It can be seen that the method of the present invention has the characteristics of low price and easy large-scale preparation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com