Integrated rapid treatment system for organic sludge

A treatment system and sludge technology, applied in the fields of sludge treatment, oxidation treatment of sludge, water/sludge/sewage treatment, etc. Pollutant reduction and other issues, to achieve the effect of convenient operation and maintenance, significant effect, and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

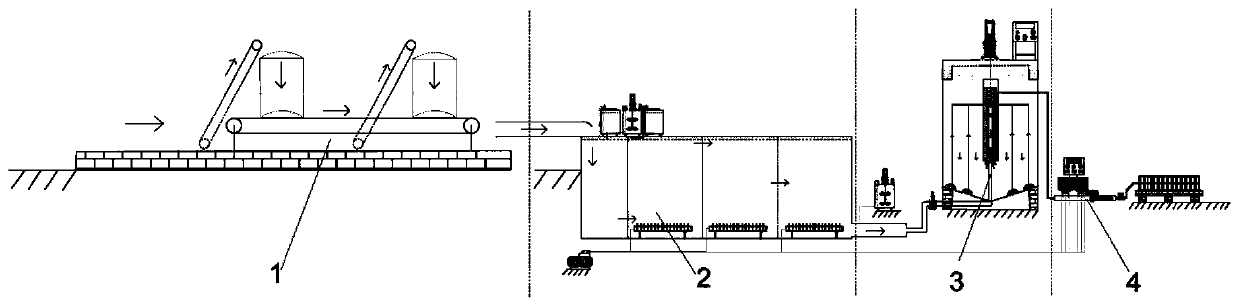

[0026] Example 1, such as figure 1 As shown, an integrated rapid treatment system for organic sludge includes an impurity removal unit 1, a sludge oxidation unit 2, a sludge rapid concentration unit 3 and a sludge rapid dehydration unit 4, an impurity removal unit 1, a sludge oxidation unit 2, and a sludge rapid concentration unit 3 and the sludge rapid dehydration unit 4 are connected in sequence; the impurity removal unit 1 is used to remove the garbage impurities in the mud; the sludge oxidation unit 2 is used to reduce the organic matter content of the sludge and destroy the extracellular polymer in the sludge through strong oxidation; the sludge is quickly concentrated Unit 3 is used to accelerate the sedimentation of particulate matter through flocculants, and then realize rapid separation of mud and water and further reduce the moisture content of sludge; rapid sludge dehydration unit 4 is used to generate gelled substances on the surface of sludge particles through high...

Embodiment 2

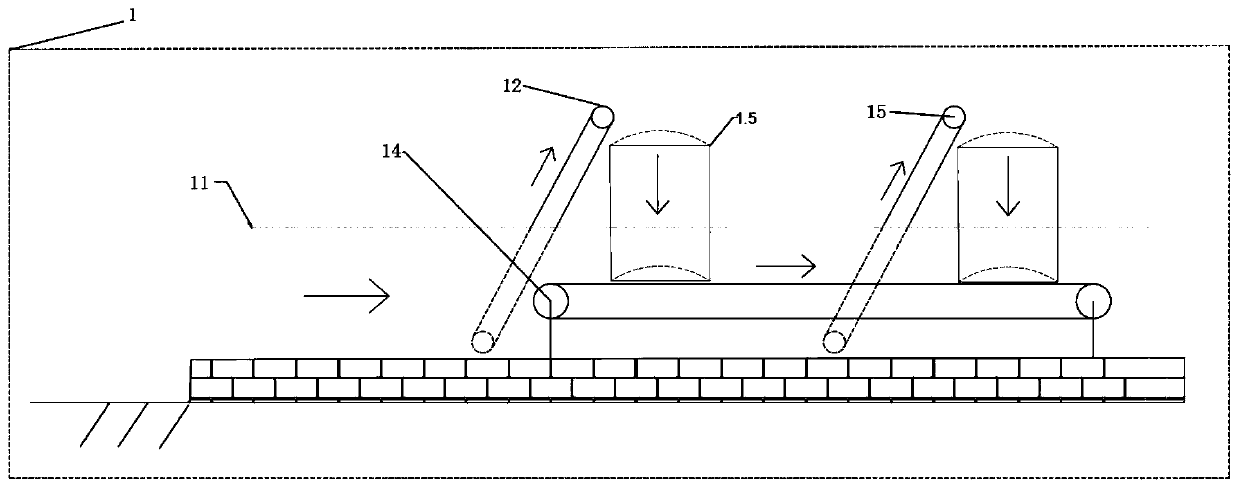

[0027] Example 2, such as Figure 1 ~ Figure 2 As shown, the present embodiment is a further improvement carried out on the basis of embodiment 1, specifically as follows:

[0028]The impurity removal unit 1 includes a mud ditch 11, a coarse grid decontamination machine 12, a fine grid decontamination machine 13, a garbage conveying device 14 and an arc plate 15, a coarse grid decontamination machine 12 and a fine grid decontamination machine 13 Place them in the mud ditch 11 at an inclination in turn, and the positions directly below the tops of the coarse grid decontamination machine 12 and the fine grid decontamination machine 13 are provided with inclined arc-shaped plates 15; the arc-shaped plates 15 are connected with the garbage conveying device 14, Shaped plate 15 preferably adopts aluminum plate. The angle between the coarse grid decontamination machine 12 and the horizontal ground is 60°~80°, the angle between the fine grid decontamination machine 13 and the horizon...

Embodiment 3

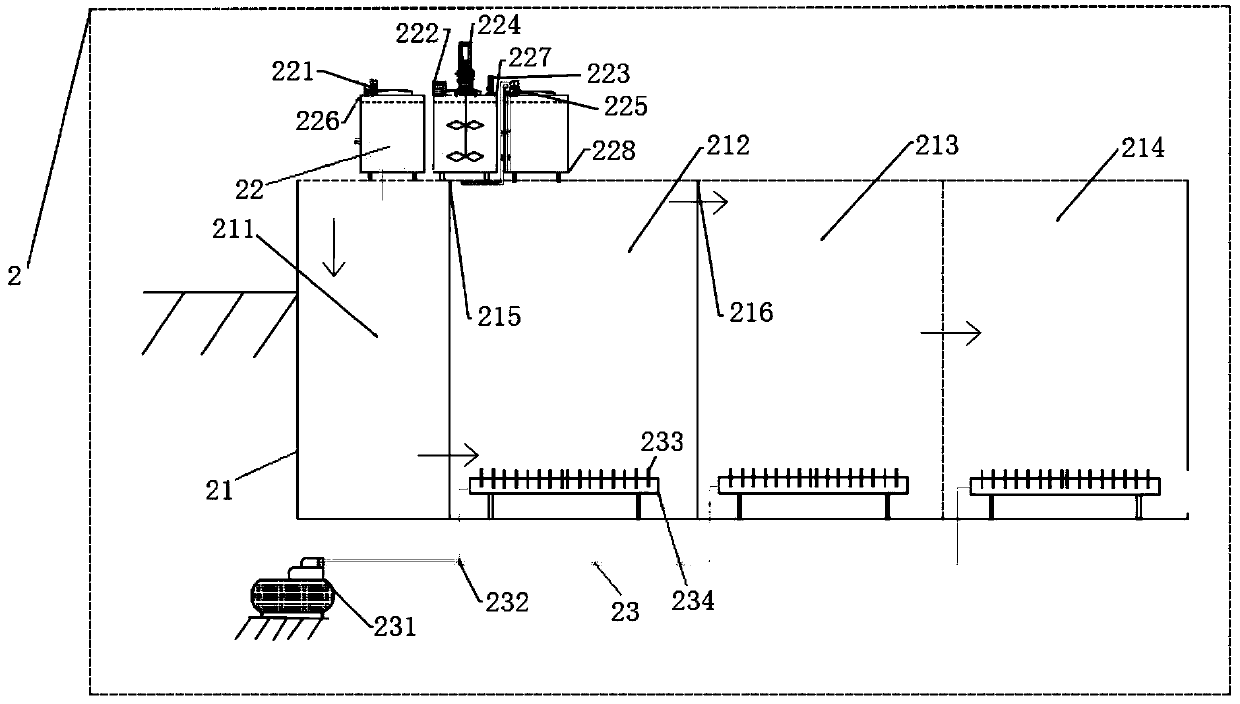

[0029] Example 3, such as Figure 1 ~ Figure 3 As shown, the present embodiment is a further improvement carried out on the basis of embodiment 1 or 2, specifically as follows:

[0030] The sludge oxidation unit 2 includes a mud tank 21, a dosing device a22 and an aeration system 23. The dosing device a22 is located at the side of the front end of the mud tank 21, and the aeration system 23 is located at the rear end of the mud tank 21; Add pH adjusting agent, metal salt and oxidizing agent in the mud pool 21, in addition, the top of the mud pool 21 is sealed with iron grid support plate, can support certain weight goods and observe the reaction situation in the pool.

[0031] The inner cavity of the mud pool 21 is composed of a continuous first compartment 211, a second compartment 212, a third compartment 213 and a fourth compartment 214. Between the first compartment 211 and the second compartment 212, there is a The first baffle 215, the convection of the mud in the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com