Filtering element chemical cleaner for prefilter of condensate polishing system and application

A technology for fine treatment of condensate and pre-filter, which is applied in the fields of filtration and separation, detergent composition, detergent compounding agent, etc., can solve the problem that the cleaning effect of filter element is not good, and the silicate scale cannot be removed more effectively. , It is impossible to fundamentally restore the fouling interception capacity of the filter element, so as to achieve the effects of easy flushing, lower operating pressure difference, and faster system commissioning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

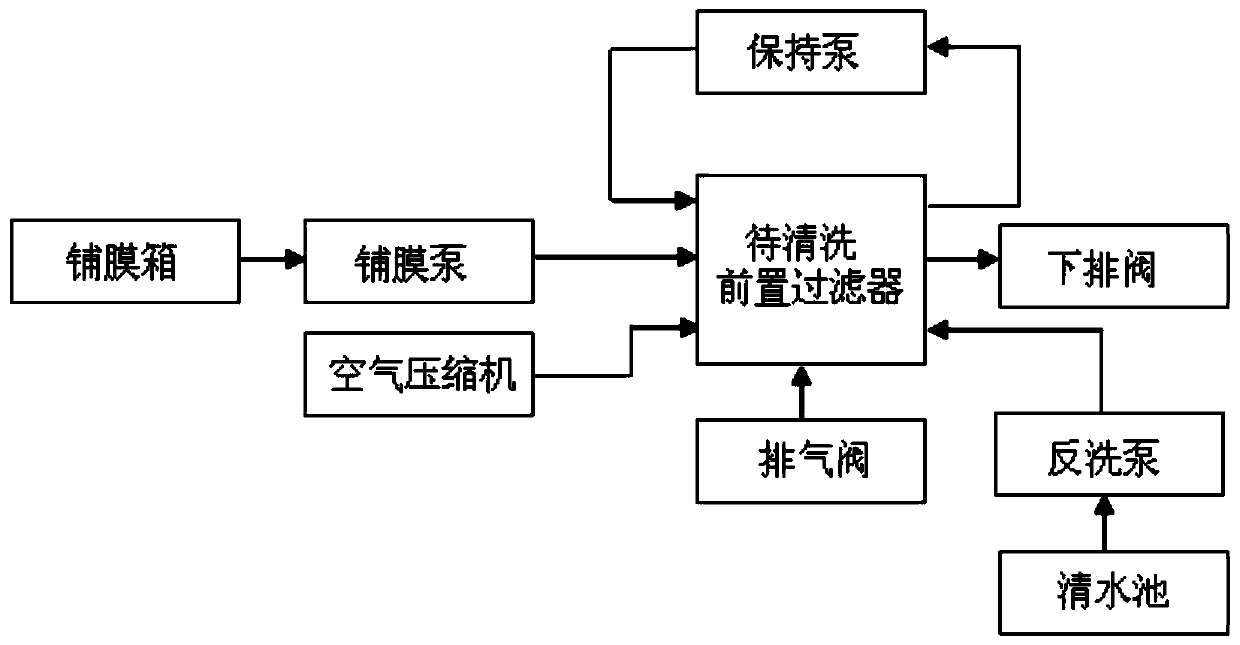

[0021] The present invention will be further described in detail below with reference to the drawings and specific embodiments.

[0022] A filter element chemical cleaning agent for the pre-filter of a condensate polishing system, comprising an alkaline cleaning agent A and an acid stripping agent B. The alkaline cleaning agent A is used to remove the oil from the filter element and includes the following components in weight ratio: Analyzed pure sodium bicarbonate 45.0~55.0%, hydrogen peroxide 35.0~45.0%, sodium dodecylbenzene sulfonate 10.0~20.0%, and its raw materials are 100.0%; acidic stripper B is used to remove silicate in the filter element , Iron oxide and copper oxide, and peeled off the surface of the filter element, including the following components by weight: analytically pure glycolic acid 45.0-50.0%, formic acid 25.0-30.0%, sodium fluoride 20.0-25.0%, and its raw materials The combined is 100.0%. The chemicals used in alkaline cleaning agent A and acid stripping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com