A kind of preparation method of aluminum-iron-vanadium-silicon alloy

A silicon alloy, aluminum-iron technology, applied in the field of aluminum-silicon overhaul slag reuse, can solve the problems of expensive raw materials, complex production process of vanadium-aluminum-iron alloy, high production cost, etc., achieve high purity, reduce anode consumption, and protect anodic oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

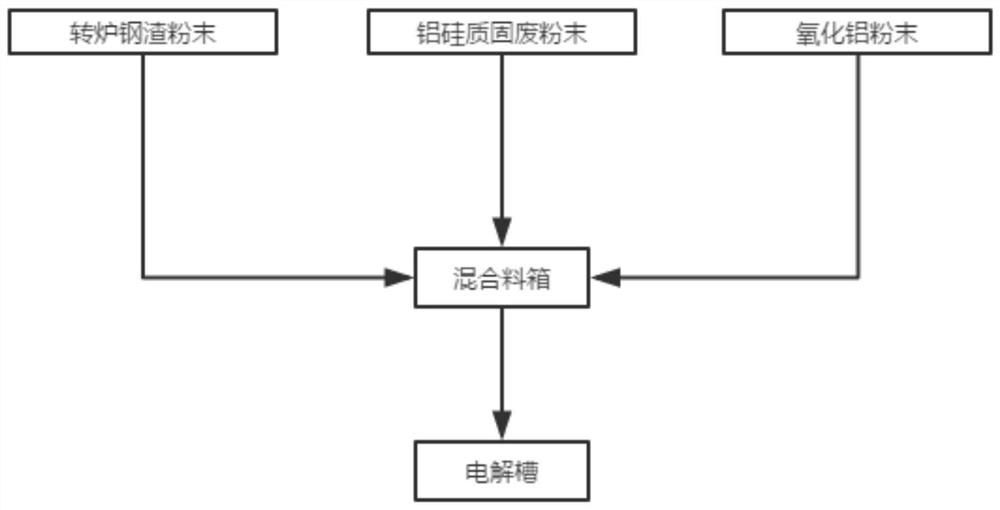

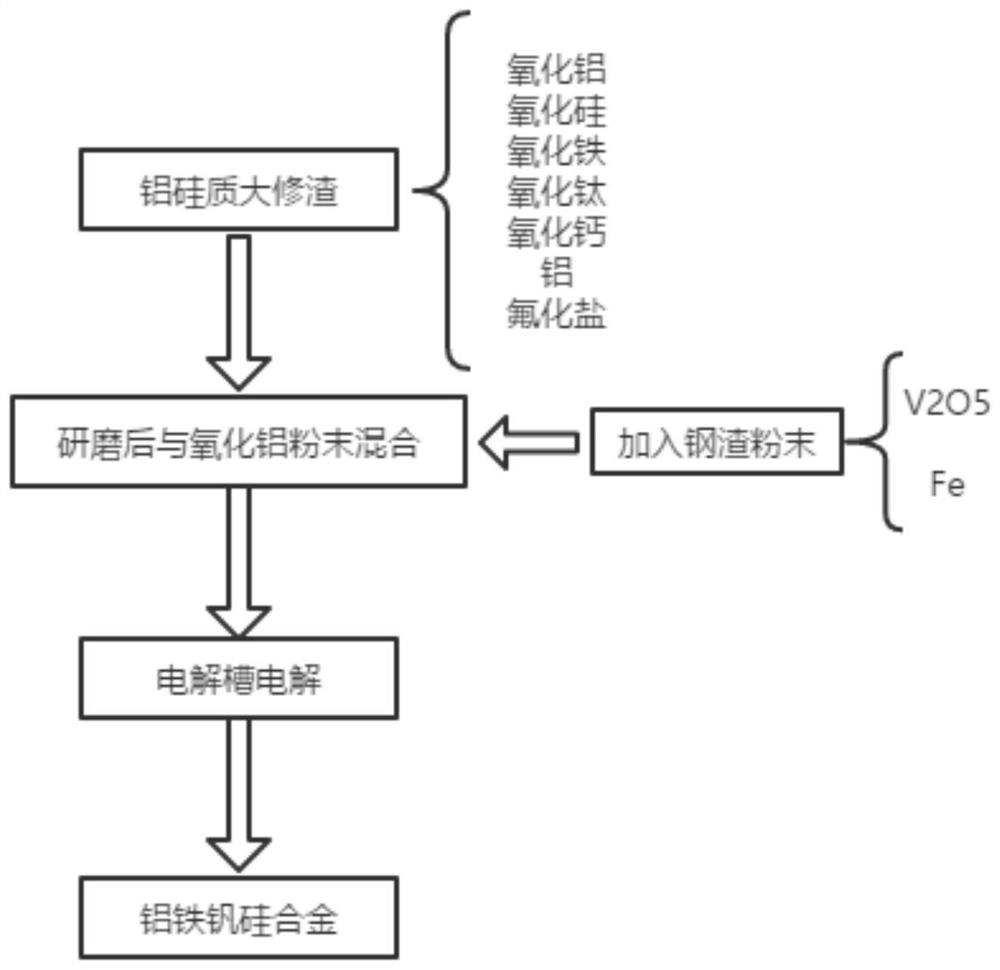

[0023] In view of the reuse of aluminum-silicon overhaul slag in the prior art, this application provides a method for preparing an aluminum-iron-vanadium-silicon alloy. The aluminum-iron-vanadium-silicon alloy prepared by electrolysis has high purity, low impurity content, and chemical High stability. On the other hand, using the electrolytic cell in the aluminum electrolysis plant as the electrolytic reaction cell does not require excessive capital investment in equipment, and the electrolysis technology is mature, which solves the problem of fluoride and cyanide in the solid waste of overhaul slag in the aluminum electrolysis industry To solve the pollution problem of chemical compounds, the harmless treatment, reduction treatment and recycling treatment of the waste lining of the aluminum electrolytic cell have been realized, and the obtained aluminum-iron-vanadium-silicon alloy is a high-value product, which has good feasibility and economy. Specifically, the preparation m...

Embodiment 1

[0042] Take the aluminum-silicon solid waste in the lining of the waste tank for crushing to obtain solid waste crushed material with a particle size of ≤0.15mm, and take converter steel slag for crushing and grinding to make powder, with a particle size of ≤02mm; the ground aluminum-silicon crushed material , alumina powder and steel slag powder are mixed in a mixing box according to a certain ratio to obtain a mixture; the Al content in the aluminosilicate overhaul slag is 16.2wt%, the Si content is 12.41wt%, and the Fe content is 3.56wt% The Fe content of the steel slag powder is 20wt%, the vanadium content is 3wt%, the weight percent content of aluminum and silicon solid waste in the mixture is 5%, the quality of the steel slag powder is 17% of the mixture quality, and alumina is the balance ;

[0043] Add the above mixture into the electrolytic cell for electrolysis. The working voltage of the electrolytic cell is 4.028V, the electrolysis temperature is 903°C, and the cur...

Embodiment 2

[0045] Take the aluminum-silicon solid waste in the lining of the waste tank for crushing to obtain solid waste crushed material with a particle size of ≤0.15mm, and take converter steel slag for crushing and grinding to make powder, with a particle size of ≤02mm; the ground aluminum-silicon crushed material , alumina powder and steel slag powder are mixed in a mixing box according to a certain ratio to obtain a mixture; the Al content in the aluminosilicate overhaul slag is 16.2wt%, the Si content is 12.41wt%, and the Fe content is 3.56wt% ; The Fe content in the steel slag powder is 20wt%, the vanadium content is 3wt%, and the weight percent content of aluminum and silicon solid waste in the mixture is 17%; the quality of the steel slag powder is 17% of the mixture quality, and the alumina quantity;

[0046] Add the above mixture into the electrolytic cell for electrolysis. The working voltage of the electrolytic cell is 4.069V, the electrolysis temperature is 924°C, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com