Self-suction type X-ray generating device and application thereof

A generation device and X-ray technology, applied in the field of X-rays, can solve the problems of increasing the volume and design complexity of the X-ray tube, increasing the manufacturing cost of the X-ray tube, and affecting the imaging effect of the X-ray tube, so as to avoid occasional outgassing and eliminate mechanical damage. Vibration, to avoid the effect of falling powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

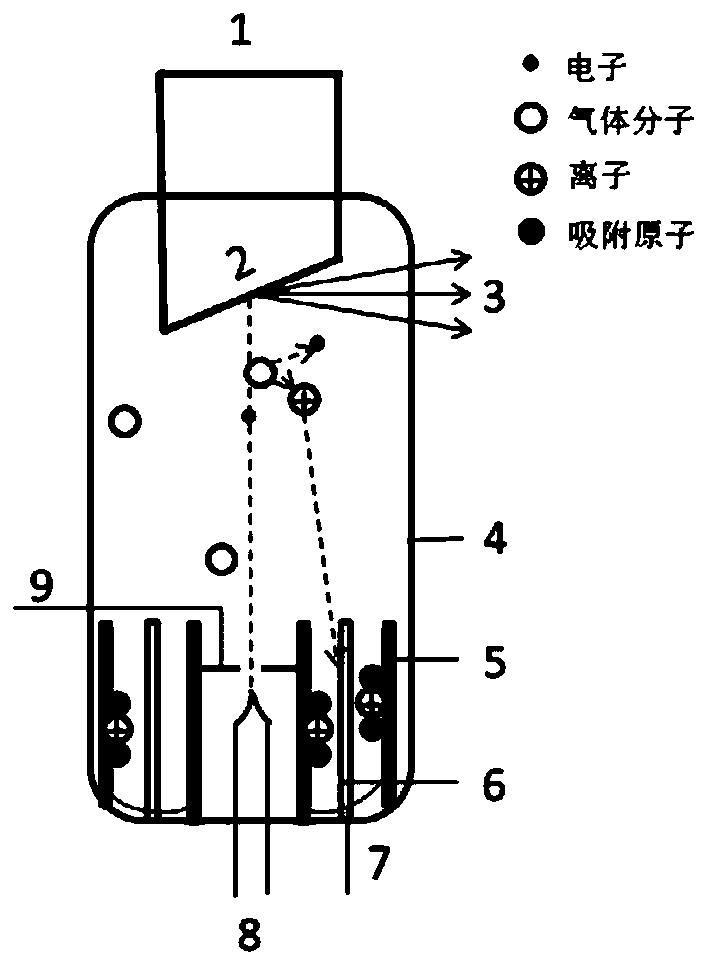

[0055] This embodiment provides a self-breathing sealed X-ray tube structure for hot cathodes, and its structural schematic diagram is as follows figure 2 As shown, it mainly includes: anode 1, target surface 2, X-ray window 3, insulating case 4, adsorption metal plate 5, sputtering metal plate 6, lead wire 7 shared by grid and adsorption metal plate, cathode 8, grid 9 .

[0056] Wherein, the cathode 8 is a filament, encapsulated in the insulating shell 4, and used for releasing electrons;

[0057] The anode 1 is packaged in the insulating case 4, the anode 1 includes a target body and a target surface 2, and the anode 1 releases X-rays by colliding with electrons released from the cathode 8;

[0058] The number of the adsorption metal plates 5 is four, the number of the sputtering metal plates 6 is two, and there are two groups of ion sputtering structures on both sides of the cathode 8, specifically, two groups of ion sputtering structures The sputtering structure is form...

Embodiment 2

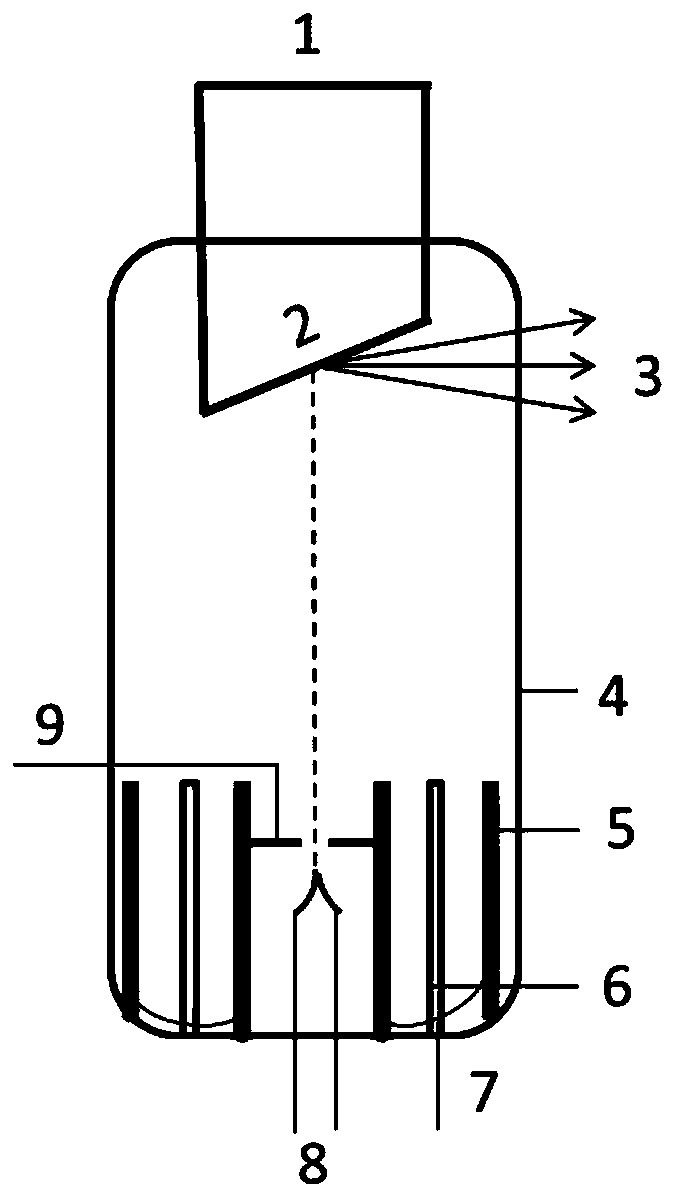

[0065] This embodiment provides a self-breathing sealed X-ray tube structure for a cold cathode, and its structural schematic diagram is as follows image 3 As shown, it mainly includes: anode 1, target surface 2, X-ray window 3, insulating case 4, adsorption metal plate 5, sputtering metal plate 6, lead wire 7 shared by grid and adsorption metal plate, cathode 8, grid 9 .

[0066] Wherein, the cathode 8 is a cold cathode, which is packaged in the insulating case 4 for releasing electrons;

[0067] The anode 1 is packaged in the insulating case 4, the anode 1 includes a target body and a target surface 2, and the anode 1 releases X-rays by colliding with electrons released from the cathode 8;

[0068] The number of the adsorption metal plates 5 is four, the number of the sputtering metal plates 6 is two, and there are two groups of ion sputtering structures on both sides of the cathode 8, specifically, two groups of ion sputtering structures The sputtering structure is forme...

Embodiment 3

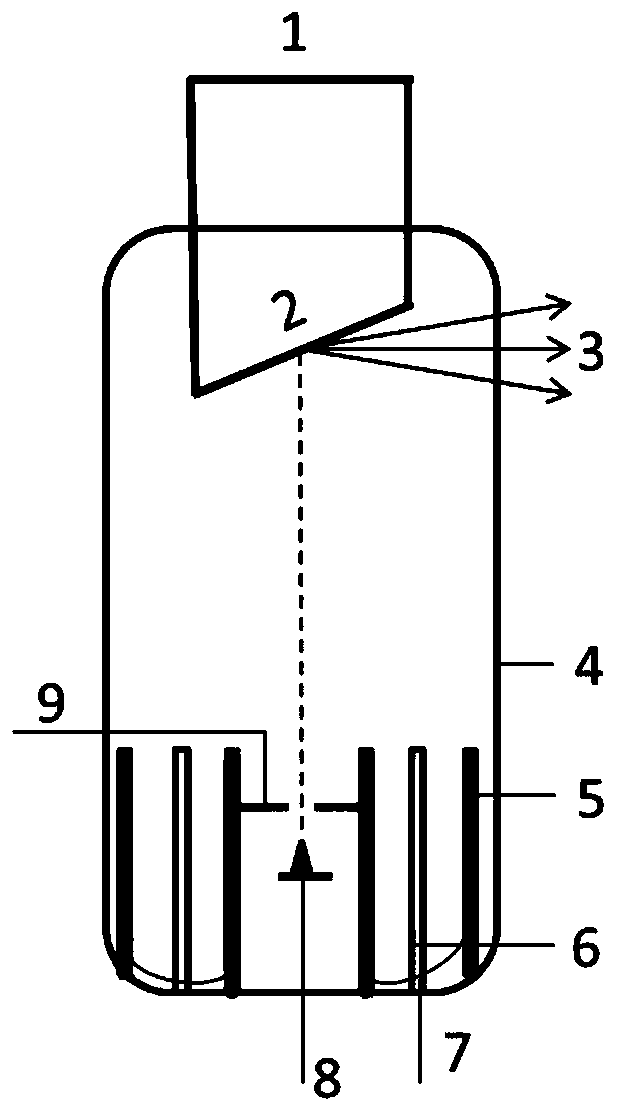

[0075] This embodiment provides a micro-focus X-ray tube for self-adsorption type cold cathode transmission target, and its structural schematic diagram is as follows Figure 4 As shown, it mainly includes: anode 1, target surface 2, X-ray window 3, insulating shell 4, adsorption metal plate 5, sputtering metal plate 6, lead wire 7 shared by grid and adsorption metal plate, cold cathode and lead wire 8, Grid 9, focusing pole 10.

[0076] The anode described in this embodiment is a transmission anode target.

[0077] The structural difference between this embodiment and Embodiment 2 is that: the X-ray tube of this embodiment further includes two focusing electrodes 10 , and these two focusing electrodes 10 are located on the electron transmission path to converge the electron beams.

[0078] By adjusting different converging electrode structures and parameters, micro-focus spot electron beams (less than 100 microns) can be realized on the target surface, and the electron beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com