Manufacturing method for silica aerogel blanket and manufacturing apparatus therefor

A technology of silica and airgel felt, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve problems such as damage, uneven impregnation, and degraded insulation performance, and achieve uniform airgel pore structure, Reduced production costs and excellent thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0095] In one embodiment of the present invention, the present invention uses a gel casting method for a continuous or semi-continuous gel preparation process wherein the formed gel is cooled. At lower temperatures, the vapor pressure of the solvent in the wet gel (silica gel felt) decreases significantly, thereby enabling a more economical process and a safer working environment. This economic benefit may be even more pronounced when solvent recovery is required when considering additional steps to recover solvent vapor. Especially at low temperatures, ie, below the flash point of the solvent, the likelihood of combustion is greatly reduced and safety for process operators is improved. Therefore, in one embodiment of the present invention, the step of distributing the gel precursor mixture at a predetermined rate so that the gel precursor mixture gels to form a silica wet gel mat; and cooling the prepared gel to reduce Steps in solvent evaporation rate.

[0096] In order to...

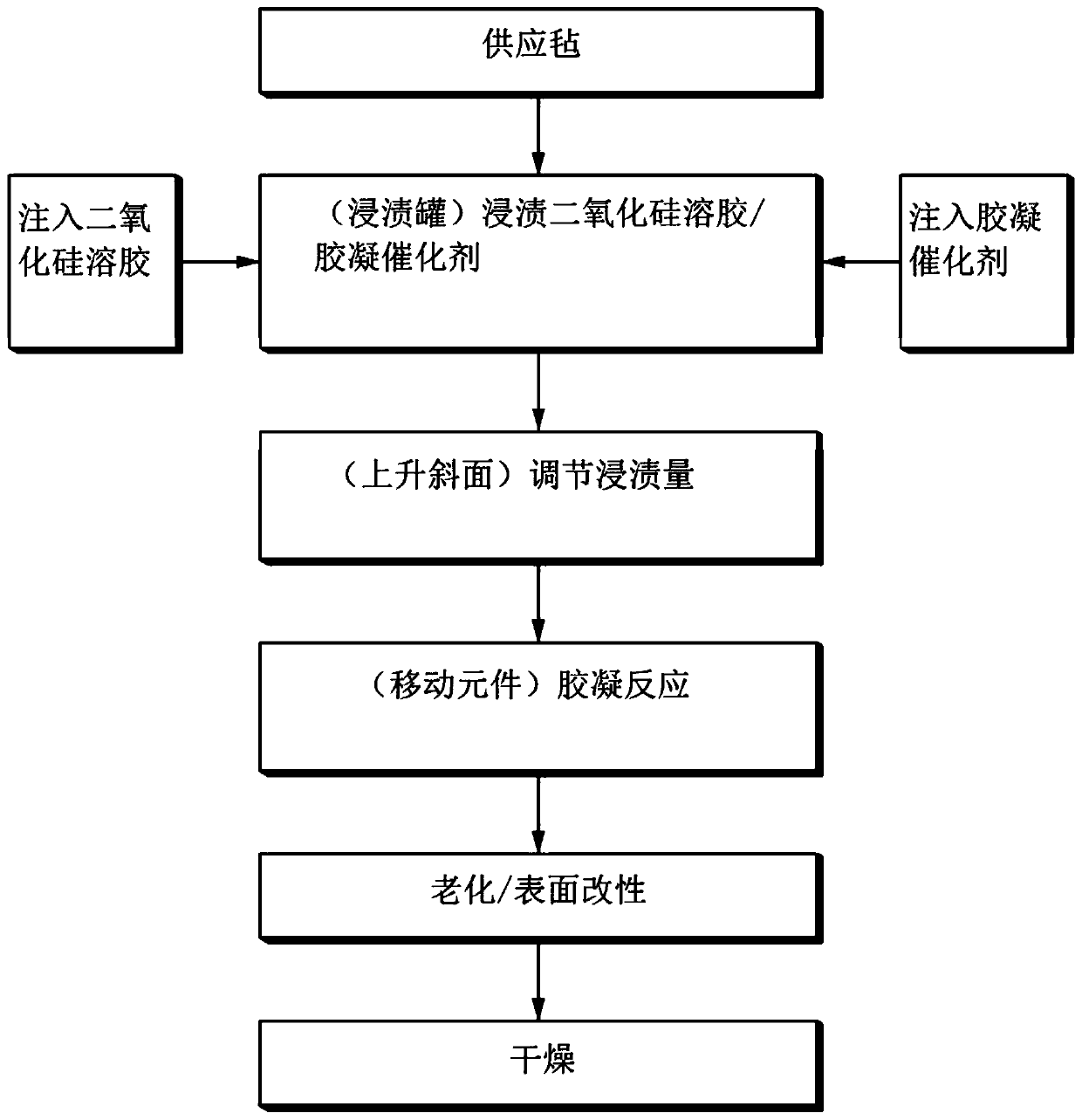

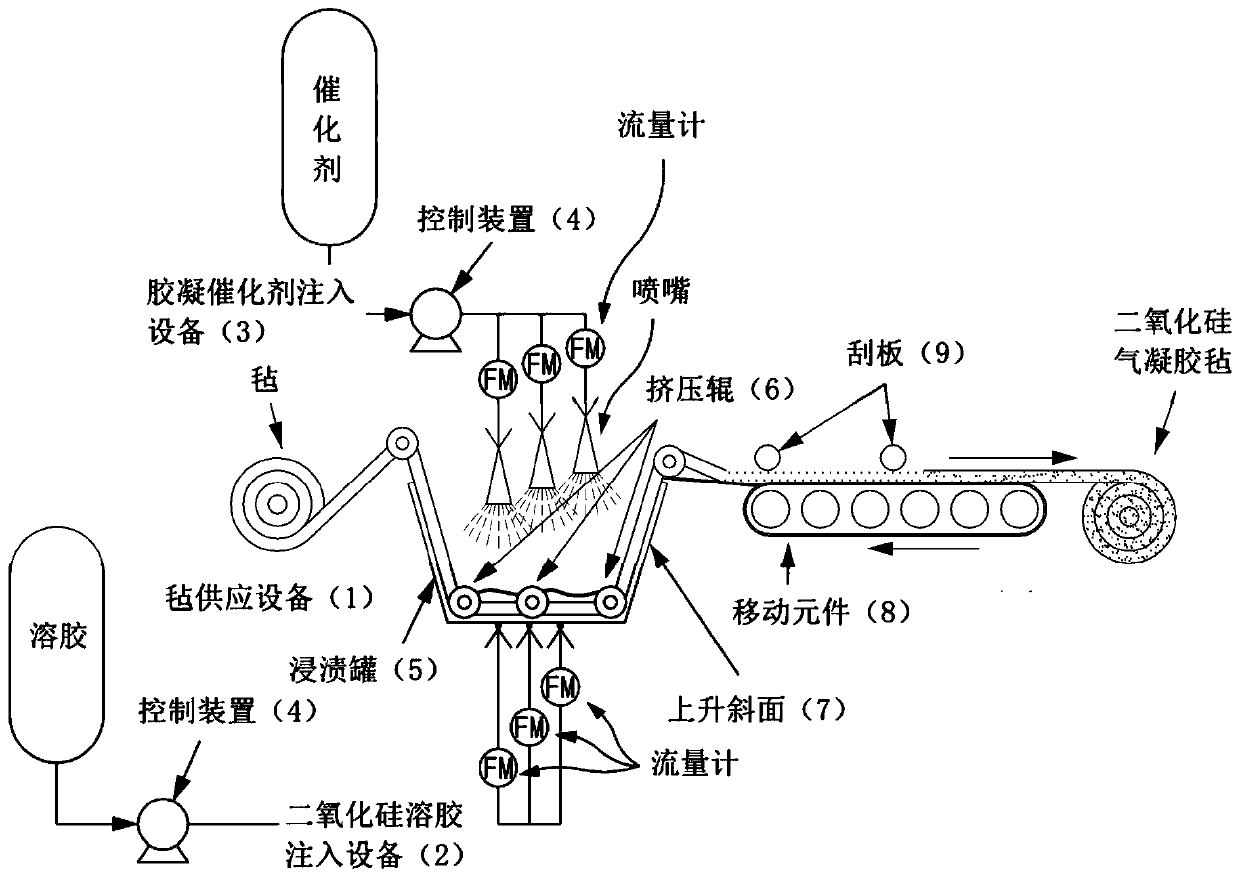

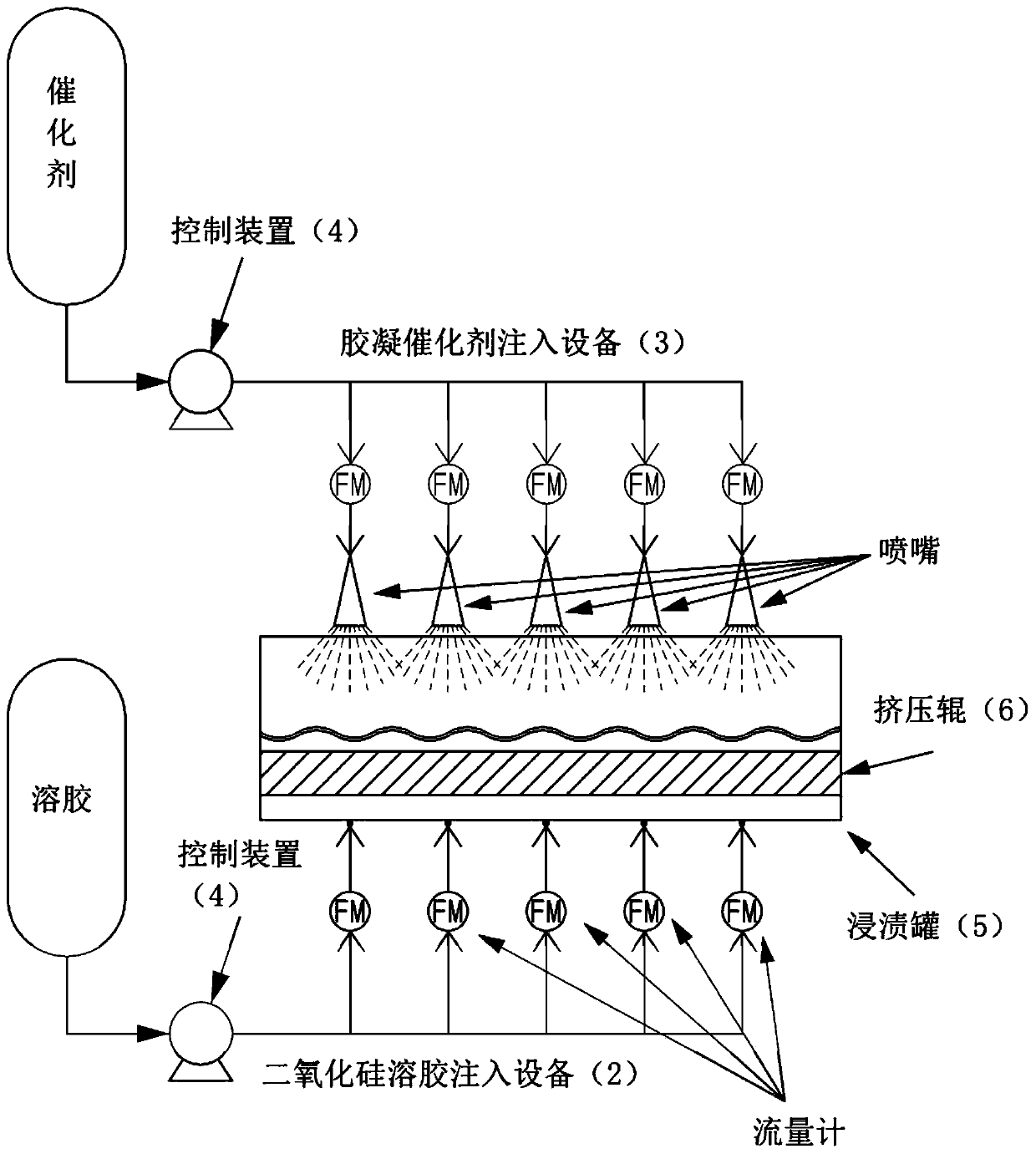

Embodiment 1

[0135] As a silica precursor, 9 kg of hydrolyzed TEOS was mixed with 27 kg of ethanol to prepare 32.5 liters of silica sol (target density (TD) 40 kg / m 3 ). Separately, mix 40.2 kg ethanol with 0.35 kg NH 4 OH (30% in water) was mixed to prepare a gelling catalyst solution. The silica sol was introduced into the impregnation tank at a constant flow rate of 1.2 L / min before the gel casting apparatus, and polyester fibers (glass fiber mat) conveyed at a constant speed were impregnated into the impregnation tank. The gelling catalyst solution was injected at 0.12 L / min onto the sol-impregnated fibers and dip tank. The fibrous mat impregnated with silica sol and gelation catalyst in the impregnation tank is then raised upwards along an incline while being conveyed at a constant speed on a conveyor belt, on which gelation takes place. The gelation was carried out for 10 minutes, and after gelation was complete, the gelled fiber mat was stabilized at room temperature (25° C.) for...

Embodiment 2 to 4

[0137] Silica airgel felt was manufactured in the same manner as in Example 1, except that 32.5 liters of silica sol (TD=60kg / m 3 、80kg / m 3 、100kg / m 3 ) and the gelling catalyst solution was added at 0.06L / min, 0.048L / min, 0.041L / min, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com