Fe2O3/TiO2 composite photocatalytic film layer with three-dimensional nano sheet structure and preparation method and application thereof

A technology of composite photocatalysis and sheet structure, which is applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., to achieve good industrial application prospects, wide range of photoresponse, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

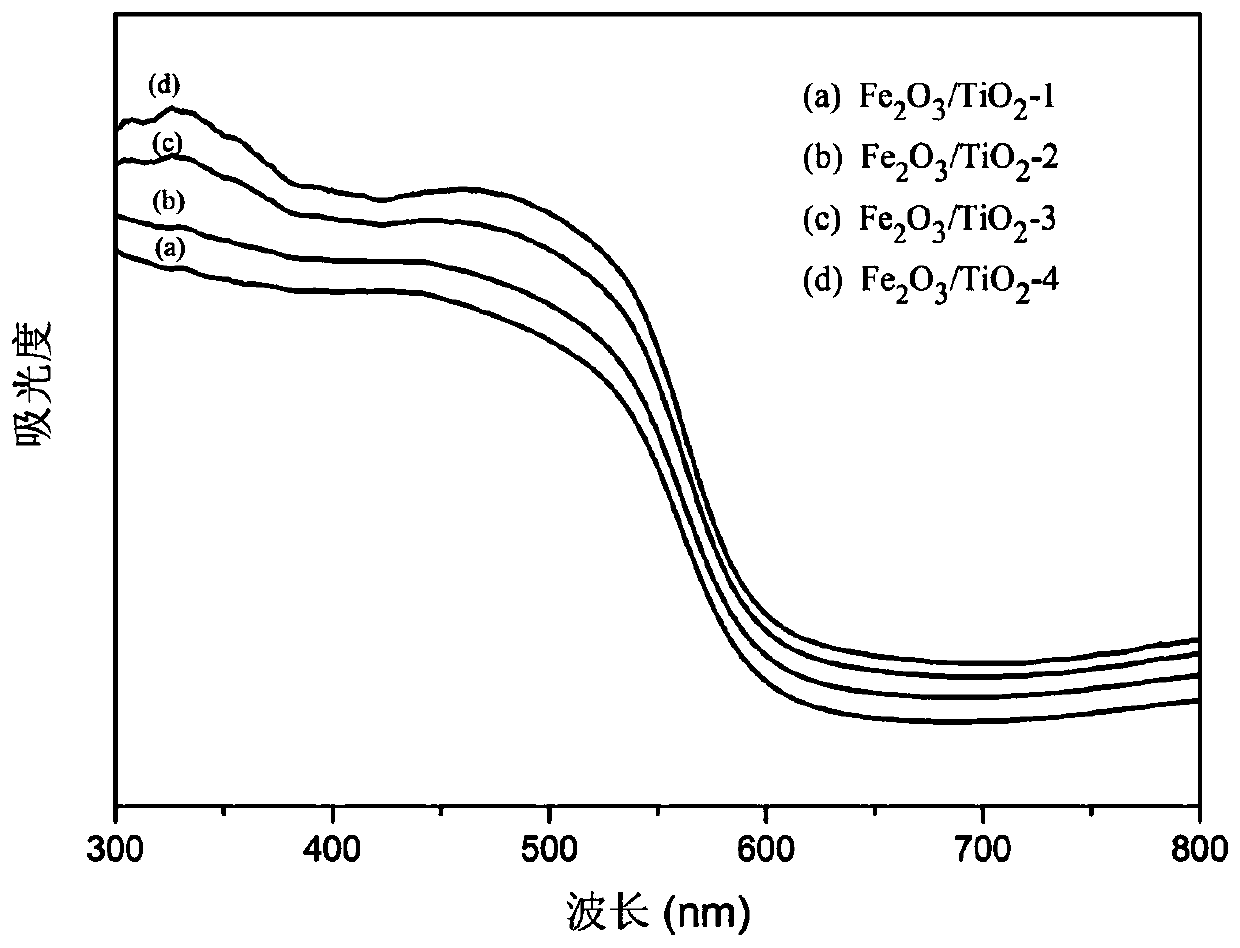

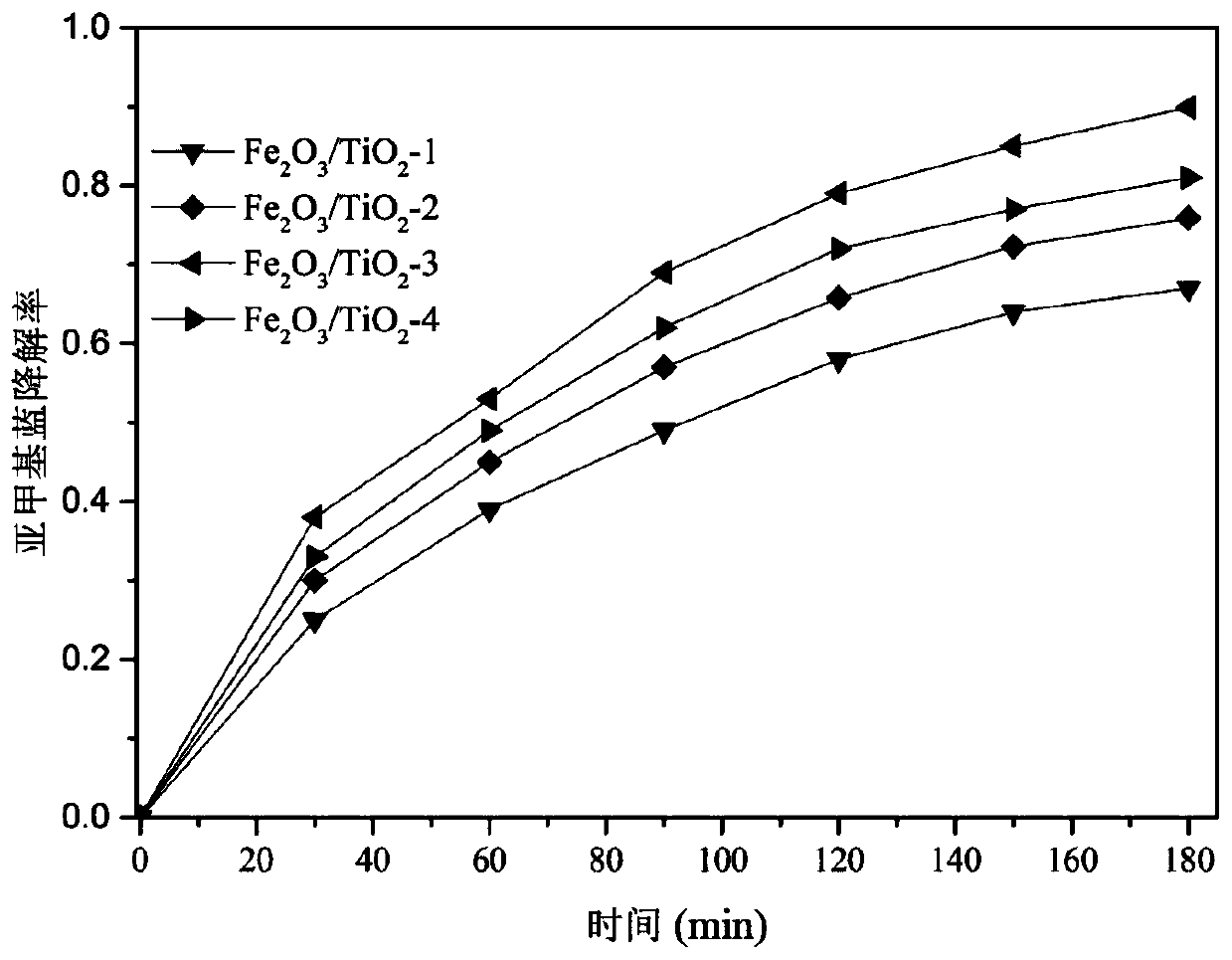

Embodiment 1

[0026] (1) Titanium substrate pretreatment: the titanium substrate is sequentially water-milled with 220#, 400#, 1000#, 2000#, 5000# sandpaper to a smooth surface, and then ultrasonically cleaned with absolute ethanol and distilled water;

[0027] (2) Preparation of plasma electrolytic oxidation carrier film: prepare electrolyte solution A containing 14 g / L sodium phosphate, 2 g / L sodium tungstate, 8 g / L potassium ferrocyanide and solvent distilled water; ) The pretreated substrate is connected to the anode of the DC power supply, and the stainless steel sheet is used as the cathode. Plasma electrolytic oxidation is performed in the reaction solution A. The reaction voltage is 360V and the reaction time is 15 minutes to obtain porous Fe 2 O 3 / TiO 2 Composite photocatalytic film;

[0028] (3) Hydrothermal treatment: prepare reaction solution B containing 0.5 M sodium hydroxide and deionized water; combine the porous Fe obtained in step (2) 2 O 3 / TiO 2 The film layer and the reactio...

Embodiment 2

[0031] (1) Titanium substrate pretreatment: the titanium substrate is sequentially water-milled with 220#, 400#, 1000#, 2000#, 5000# sandpaper to a smooth surface, and then ultrasonically cleaned with absolute ethanol and distilled water;

[0032] (2) Preparation of plasma electrolytic oxidation carrier film: prepare electrolyte solution A containing 14 g / L sodium phosphate, 2 g / L sodium tungstate, 8 g / L potassium ferrocyanide and solvent distilled water; ) The pretreated substrate is connected to the anode of the DC power supply, and the stainless steel sheet is used as the cathode. Plasma electrolytic oxidation is performed in the reaction solution A, the reaction voltage is 360V, and the reaction time is 15 minutes to obtain porous Fe 2 O 3 / TiO 2 Composite photocatalytic film;

[0033] (3) Hydrothermal treatment: prepare reaction solution B containing 0.5 M sodium hydroxide and deionized water; combine the porous Fe obtained in step (2) 2 O 3 / TiO 2 The film layer and reaction s...

Embodiment 3

[0036] (1) Titanium substrate pretreatment: the titanium substrate is sequentially water-milled with 220#, 400#, 1000#, 2000#, 5000# sandpaper to a smooth surface, and then ultrasonically cleaned with absolute ethanol and distilled water;

[0037] (2) Preparation of plasma electrolytic oxidation carrier film: prepare electrolyte solution A containing 14 g / L sodium phosphate, 2 g / L sodium tungstate, 8 g / L potassium ferrocyanide and solvent distilled water; ) The pretreated substrate is connected to the anode of the DC power supply, and the stainless steel sheet is used as the cathode. Plasma electrolytic oxidation is performed in the reaction solution A, the reaction voltage is 360V, and the reaction time is 15 minutes to obtain porous Fe 2 O 3 / TiO 2 Composite photocatalytic film;

[0038] (3) Hydrothermal treatment: prepare reaction solution B containing 0.5 M sodium hydroxide and deionized water; combine the porous Fe obtained in step (2) 2 O 3 / TiO 2 The film layer and reaction s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com