Cobalt oxyhydroxide and preparation method thereof, lithium cobaltate, electrode and lithium ion battery

A technology of cobalt oxyhydroxide and lithium cobalt oxide is applied in the fields of lithium cobalt oxide, cobalt oxyhydroxide and their preparation, electrodes and lithium ion batteries, which can solve the problems of low specificity, unsuitable charging and discharging performance for supercapacitors, etc. Effects of excellent, good ion scattering behavior, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A cobalt chloride aqueous solution with a concentration of 70 g / L was configured as a cobalt salt solution; an aqueous potassium hydroxide solution with a mass concentration of 32% was configured as an alkaline solution, and magnesium chloride was dissolved in pure water to configure a doping solution with a concentration of 0.4 g / L; The aqueous solution of sodium hypochlorite is used as the oxidant, and the disodium EDTA is used as the complexing agent.

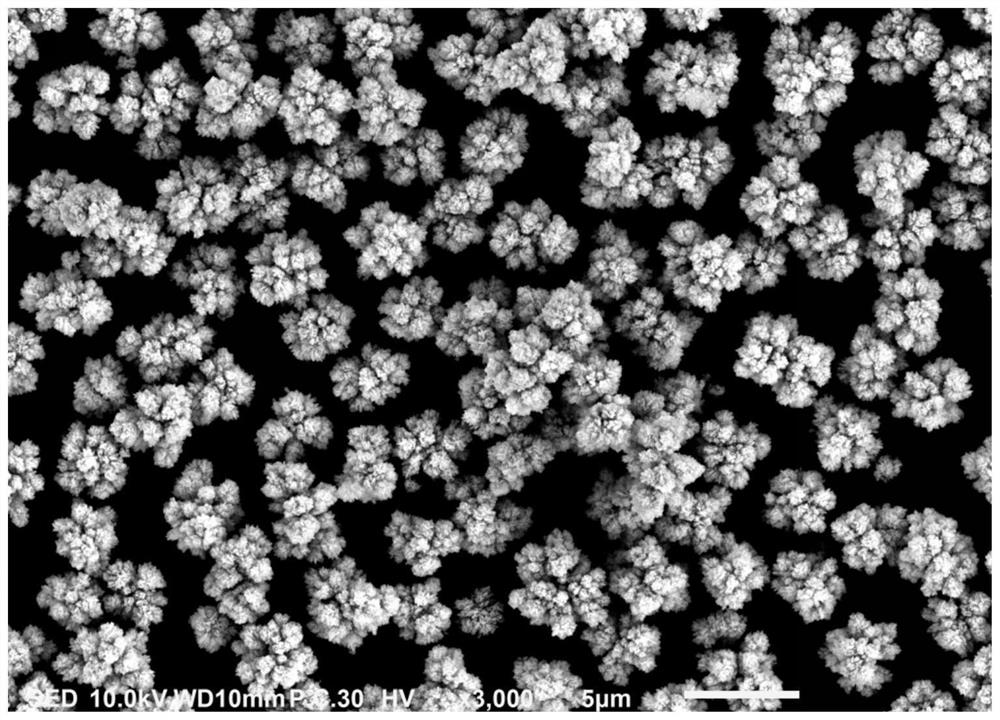

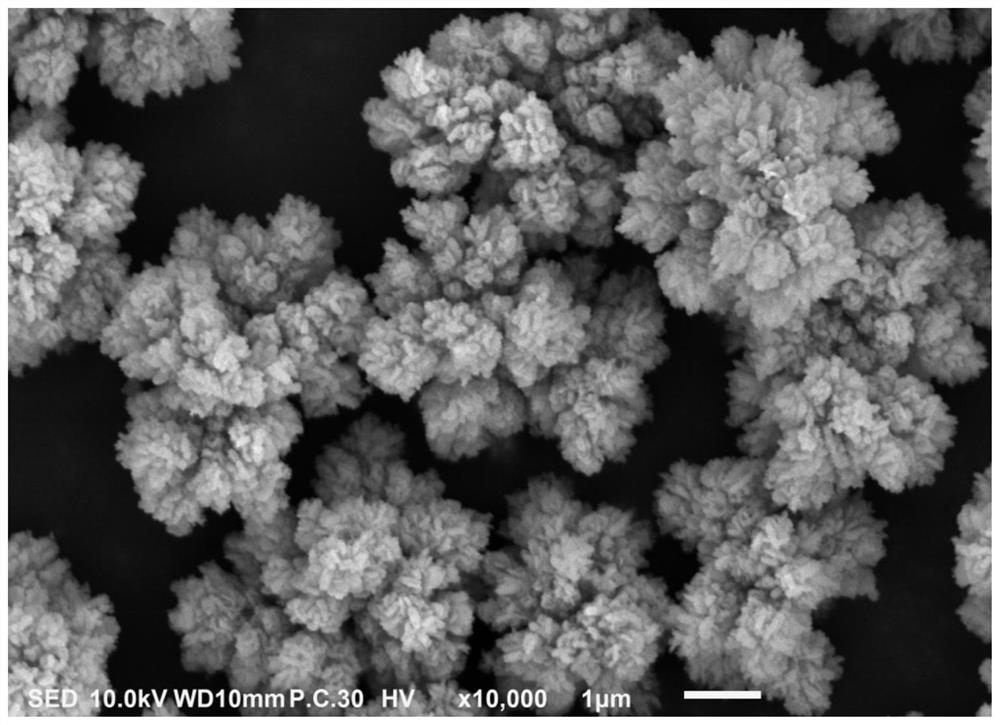

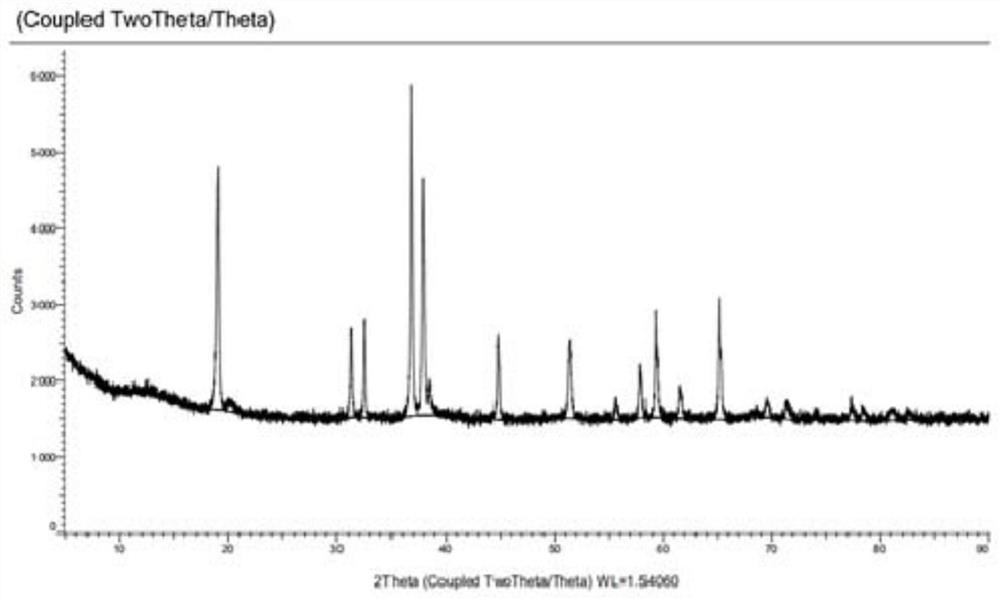

[0070] Control the mass ratio of cobalt salt to oxidant to be 10:1, and the mass ratio of cobalt salt to complexing agent to be 50:1. Add cobalt salt solution, doping solution, alkaline solution, oxidant, complexing agent and pure water to 100L of reaction In the kettle, the stirring speed was controlled to 2000rmp, the reaction temperature was 50°C, and pH=9. After reacting for a period of time, the material is discharged to obtain flower-shaped cobalt oxyhydroxide with a particle size of 3-4 μm.

[0071] The prepar...

Embodiment 2

[0073] A cobalt sulfate aqueous solution with a concentration of 160 g / L was configured as a cobalt salt solution; a sodium hydroxide aqueous solution with a mass concentration of 32% was configured as an alkaline solution, and aluminum sulfate was dissolved in part of the alkaline solution, and pure water was added to configure a concentration of 0.6 g / L. Doping solution; Sodium peroxide solution is used as oxidant and EDTA is used as complexing agent.

[0074] The mass ratio of cobalt salt to oxidant is controlled to be 15:1, and the mass ratio of cobalt salt to complexing agent is 100:1. The cobalt salt solution, doping solution, remaining alkaline solution and oxidant are added to the device at a flow rate of 1L / h. In a 100L reaction kettle with a complexing agent and pure water, the stirring speed was controlled to 4000rmp, the reaction temperature was 70°C, and the pH was 10. After reacting for a period of time, the material is discharged to obtain cobalt oxyhydroxide. ...

Embodiment 3

[0079] A cobalt nitrate aqueous solution with a concentration of 150 g / L was configured as a cobalt salt solution; a lithium hydroxide aqueous solution with a mass concentration of 32% was configured as an alkaline solution, and nickel sulfate was dissolved in pure water to configure a doping solution with a concentration of 0.5 g / L; Sodium perchlorate is used as oxidant and amino acid is used as complexing agent.

[0080] The mass ratio of cobalt salt and oxidant is controlled to be 12:1, and the mass ratio of cobalt salt to complexing agent is 60:1. The cobalt salt solution, doping solution, alkali solution and oxidant are added to the complex with a flow rate of 3L / h. In the 100L reaction kettle of the mixture and pure water, the stirring speed was controlled to 3000rmp, the reaction temperature was 55°C, and the pH was 11. After reacting for a period of time, the material is discharged to obtain cobalt oxyhydroxide.

[0081] The cobalt oxyhydroxide is passed into the cent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com