Method for preparing ultra-thick hard thin film based on energy regulation principle

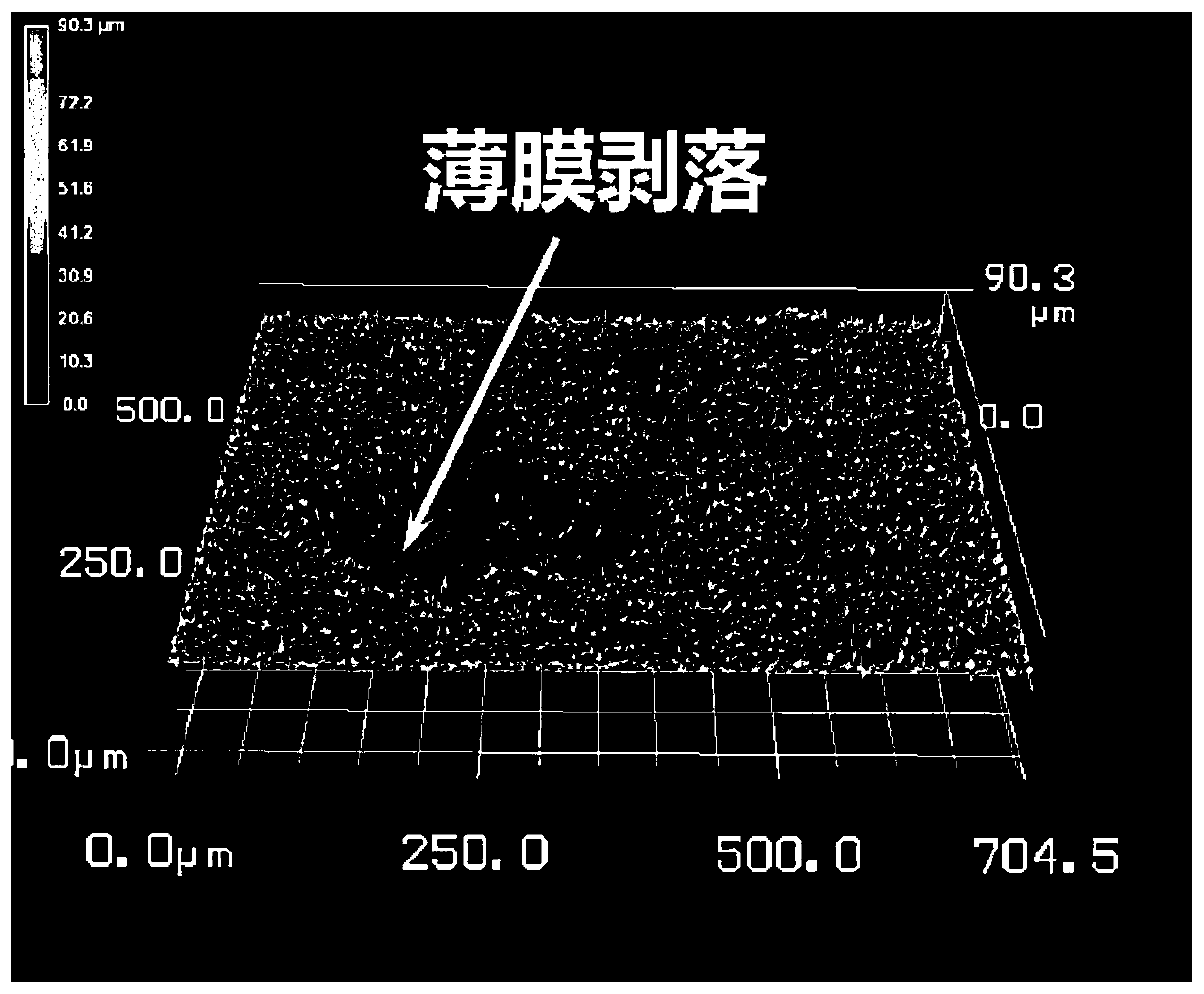

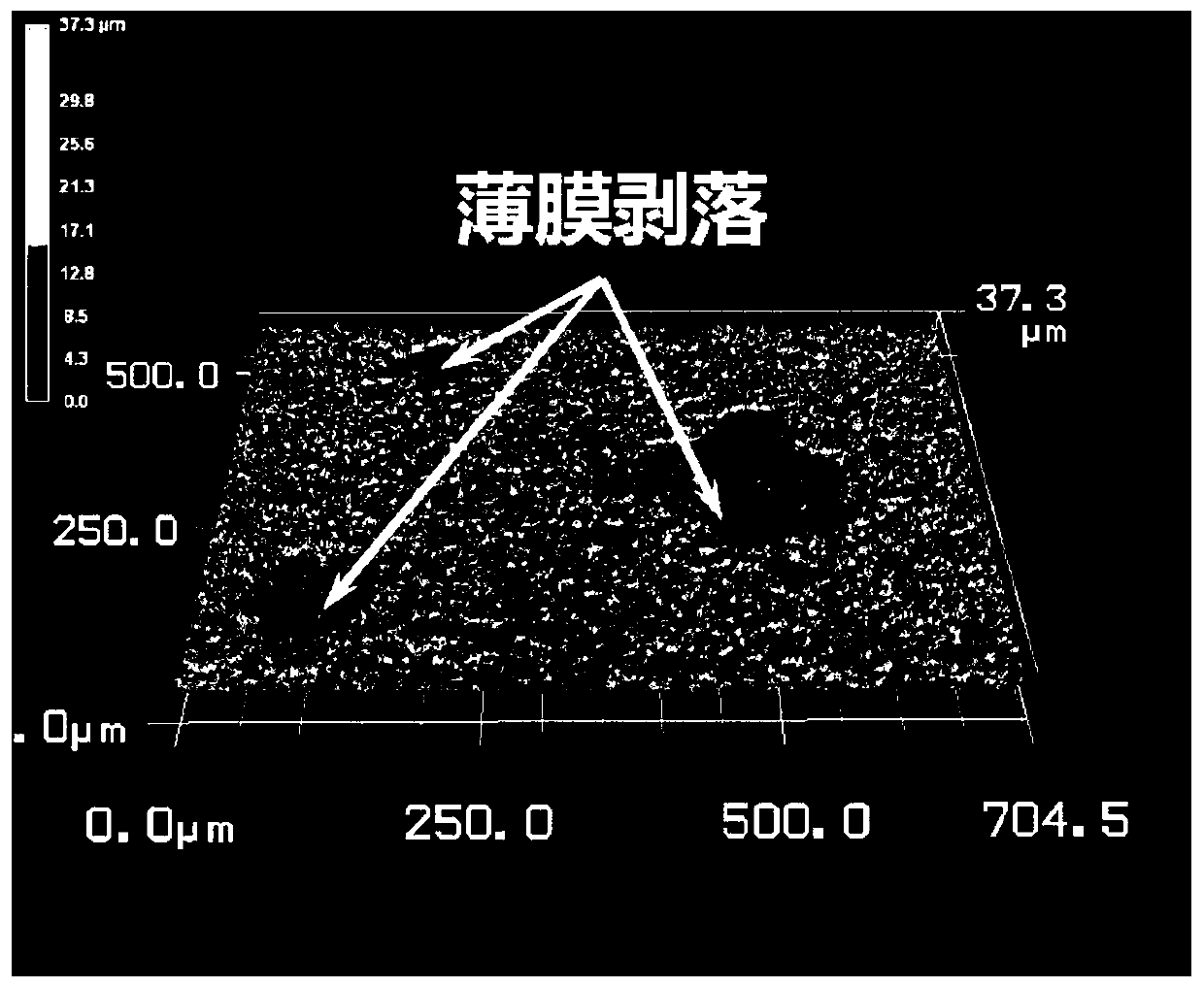

An energy regulation and thin film technology, which is applied in the field of ultra-thick hard thin films based on the principle of energy regulation, can solve the problems of not forming a technical system, film fragmentation, and costing a lot of money, so as to avoid film cracking and peeling problems, optimize the film Layer structure, the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The method of the present embodiment comprises the following steps:

[0037] Step 1. Put the high-speed steel substrate in sequence in analytically pure acetone and analytically pure ethanol for ultrasonic cleaning for 20 minutes, and then dry it with a hot air blower to obtain a clean high-speed steel substrate;

[0038] Step 2, fix the Ti arc target on the target base of the multi-arc ion plating equipment, put the clean high-speed steel substrate obtained in step 1 into the vacuum chamber of the multi-arc ion plating equipment and fix it on the sample holder of the turntable, Then close the door of the vacuum chamber, turn on the mechanical pump and the molecular pump in turn to evacuate the vacuum chamber to a vacuum degree of 5.0×10 -3 At Pa, turn on the switch of the heating device and heat the vacuum chamber to 300°C;

[0039] Step 3. Continue to evacuate the vacuum chamber heated to 300°C in step 2 until the vacuum degree is lower than 5.0×10 -3 Pa, then pass ...

Embodiment 2

[0058] The difference between this embodiment and Embodiment 1 is that the substrate used is a Si substrate.

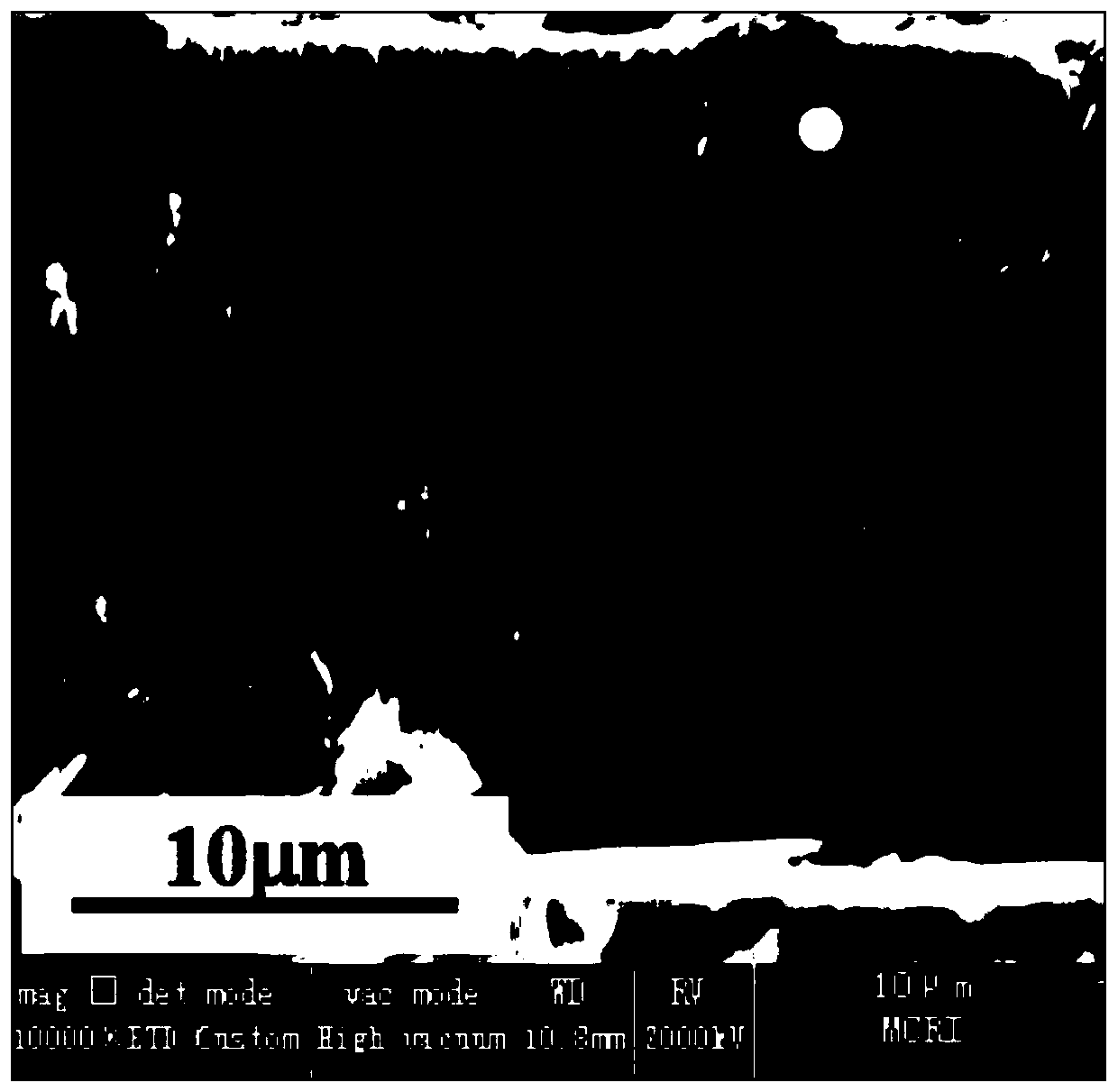

[0059] Figure 4 It is the cross-sectional electron micrograph of the ultra-thick TiN film obtained on the surface of the Si substrate in this embodiment, from Figure 4 It can be seen that the thickness of the ultra-thick TiN thin film prepared in this example is 22.5 μm, and the structure of the film layer is dense.

Embodiment 3

[0061] Step 1. Put the high-speed steel substrate in sequence in analytically pure acetone and analytically pure ethanol for ultrasonic cleaning for 20 minutes, and then dry it with a hot air blower to obtain a clean high-speed steel substrate;

[0062] Step 2, fix the Ti arc target on the target base of the multi-arc ion plating equipment, put the clean high-speed steel substrate obtained in step 1 into the vacuum chamber of the multi-arc ion plating equipment and fix it on the sample holder of the turntable, Then close the door of the vacuum chamber, turn on the mechanical pump and the molecular pump in turn to evacuate the vacuum chamber to a vacuum degree of 3.0×10 -3 At Pa, turn on the switch of the heating device and heat the vacuum chamber to 350°C;

[0063] Step 3. Continue to evacuate the vacuum chamber heated to 350°C in step 2 until the vacuum degree is lower than 3.0×10 -3 Pa, then pass argon into the vacuum chamber and maintain a vacuum of 3.0Pa, and turn on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com