Novel RO membrane

A new type of membrane-supporting technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as high cost and easy clogging, and achieve low cleaning frequency, easy cleaning, anti-pollution performance and self-cleaning powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: the preparation of novel RO membrane

[0019] Source of test material: Hydrophobic methyltrichlorosilane (MeSiCl 3 , MTS, >99%, purchased from Sigma-Aldrich) as precursors, L-(+)-camphorsulfonic acid (CSA, >99%), m-phenylenediamine (MPD, ≥99%, purchased from Sigma-Aldrich) , isoparaffin solvent Isopar G (purchased from ExxonMobil), triethylamine (TEA, ≥99%, purchased from Sigma-Aldrich), m-phenylenediamine (MPD, >99%, purchased from Sigma-Aldrich) , Chloroform (CHCl 3 , ≥99%, purchased from Sigma-Aldrich), 1,3,5-trichlorotricarbonylbenzene (TMC, ≥98%, purchased from Sigma-Aldrich), purchased from Sigma-Aldrich), bovine serum albumin (BSA , ≥96%, purchased from Sigma-Aldrich), sodium alginate (SA, >99%, purchased from Sigma-Aldrich), humic acid (HA, >90%, purchased from Sigma-Aldrich), polysulfone support membrane (PSF support membrane, purchased from Sigma-Aldrich).

[0020] The preparation process of the new RO membrane is as follows: 135mM CSA is com...

Embodiment 2

[0021] Embodiment 2: parameter determination

[0022] During the preparation of the new RO membrane, MTS reacts with amino groups and hydroxyl groups, and an ammonolysis reaction occurs between MTS and amines. Due to the above reactions, MTS is covalently attached to the PA polymer, and MTS is converted into methylsilane through water-mediated Alcohol, the HCl released by MTS during the reaction changes the interfacial polymerization state, which in turn changes the morphology and transport properties of the film. The organic group methyl group can be extended from the PA matrix and introduce the required functions. The methyl group makes the polyamide The surface energy of the membrane is reduced, resulting in greater hydrophobicity. The non-selective voids at the interface of MTS and PA polymers are reduced, and the affinity between water and pore walls is lower, which accelerates the penetration of water.

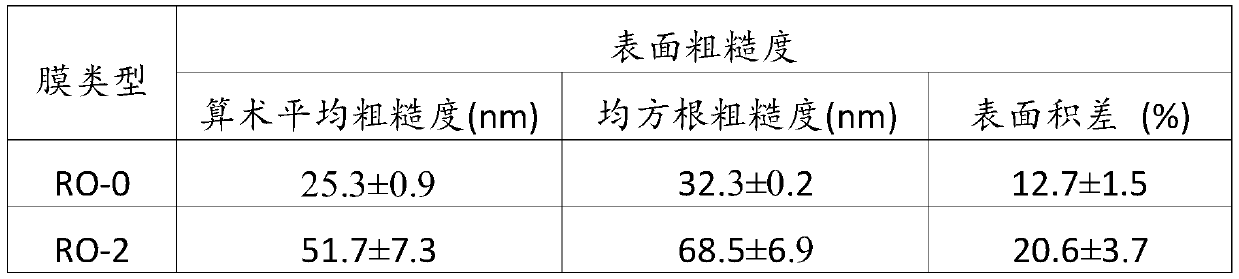

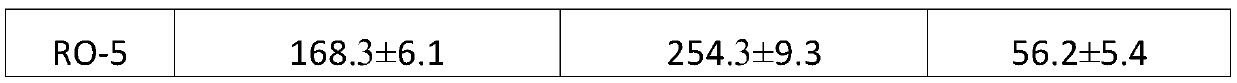

[0023] The surface roughness of the new RO membrane was measured u...

Embodiment 3

[0027] Example 3: New RO membrane pure water desalination test flux measurement

[0028] The pure water flux and desalination test of the membrane was tested by a cross-flow filtration system at a cross-flow rate of 68L / h at 25°C and different pressures of 5, 10, 15 and 20bar. Before the test, the membrane was placed in Stable for at least 1 h under different pressures. Desalination tests were evaluated with an aqueous feed solution containing 2000 ppm NaCl. The pure water flux J (L·m-2·h-1, LMH) is calculated by J=V / (A×Δt), where V is the permeation volume of the solution, A is the membrane area, and Δt is the permeation time. The pure water permeability coefficient A(LMH / bar) is modeled by linear fx, A=J / ΔP, where ΔP represents different pressures. The test results show that RO-5 membrane permeability increases by about 214% compared to RO-0, and does not affect water / salt selectivity. The RO-2 membrane permeability increased by about 132.5% compared to RO-0 without affec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com