Pressure-driven multi-channel droplet quantitative measuring device and measuring method

A multi-channel, droplet technology, applied in the microfluidic field of analytical chemistry, can solve the problem that it cannot be used to quantitatively measure liquids of unknown viscosity, and achieve the effect of easy large-scale parallelization, convenient operation and high-throughput characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

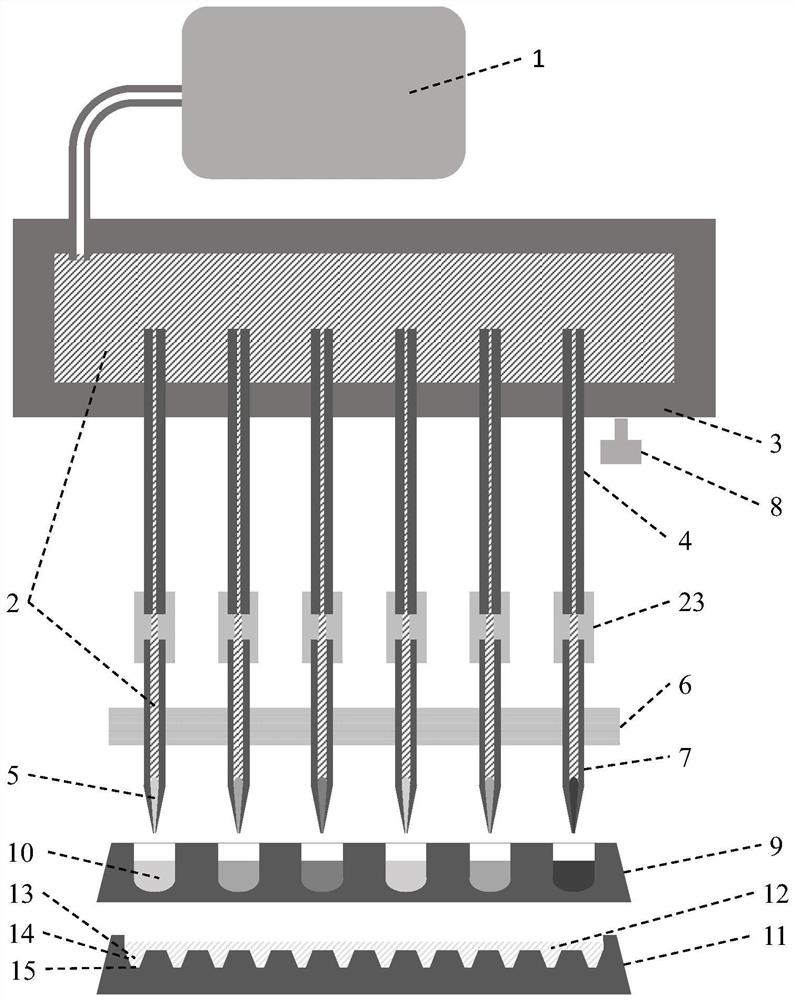

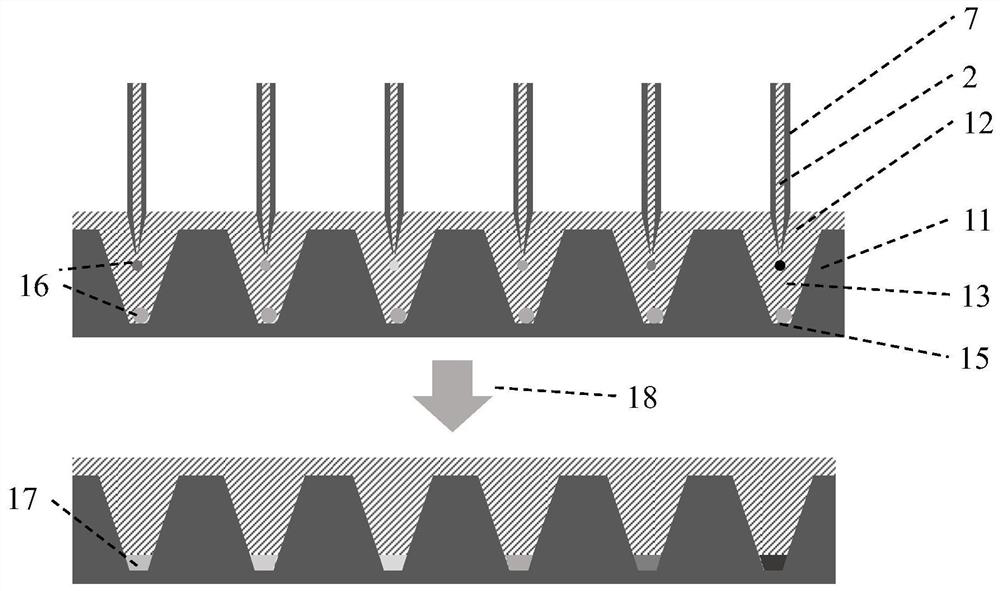

[0082] This example applies the present invention to the screening of protein crystallization conditions. Such as figure 1 and figure 2 As shown, a pressure-driven multi-channel liquid droplet quantitative measuring device includes:

[0083] Pressure source and pressure control system 1, which can provide positive and negative pressure sources and control the magnitude and application time of pressure;

[0084] The working medium reservoir 3 is used to hold the working medium 2 with known viscosity-temperature relationship;

[0085] Temperature sensor 8, capable of measuring the working environment temperature;

[0086] The fluid damper 4, its liquid inlet end is connected with the working medium liquid storage pool 3 and communicated with its medium cavity;

[0087] The sampling probe 7 is hermetically connected with the liquid outlet end of the fluid damper 4 through the connector 23;

[0088] The fixture 6 is used for positioning and fixing the array formed by the spo...

Embodiment 2

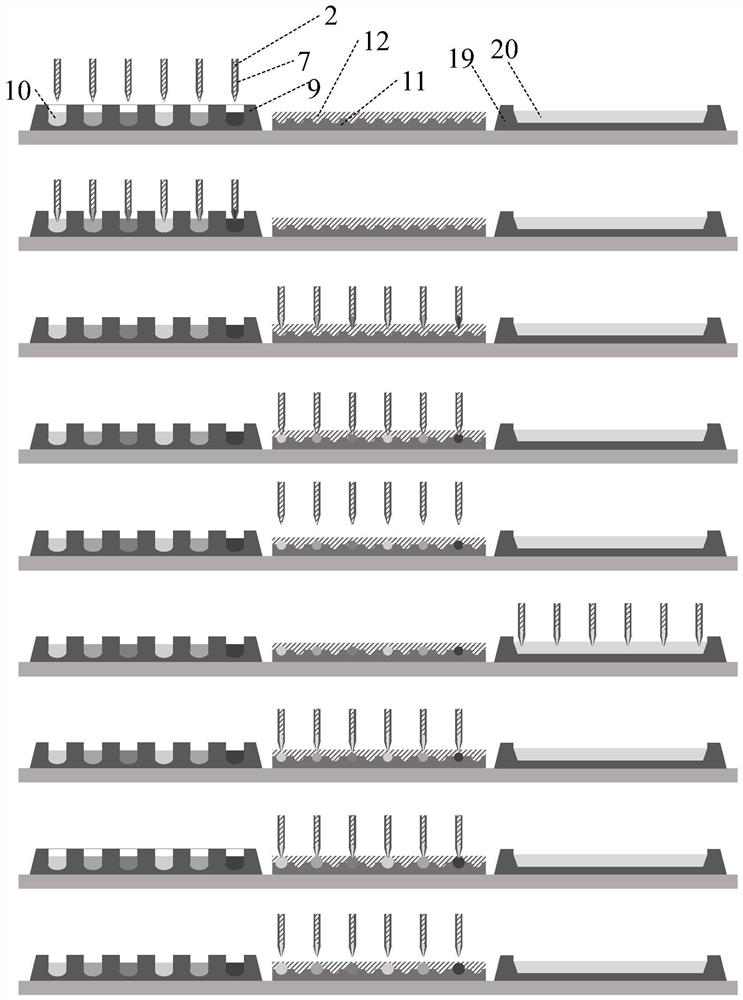

[0102] In this embodiment, a droplet array composed of different drug solutions is firstly generated, and a quantitative dilution operation is performed on the droplets therein.

[0103] Such as image 3 As shown, in this embodiment, the multi-channel droplet quantitative measuring device is similar to that of Embodiment 1, but the number of channels is 6. The multi-channel droplet quantitative measuring device is also installed on the automatic translation platform, and the automatic translation platform is controlled by a computer program.

[0104] In this embodiment, the porous plate 9 is a 24-well plate, the sample solution 10 is an aqueous solution of 24 different drugs, the chip 11 is a glass chip with micropits, and the working medium 12 is mineral oil. Another liquid storage tank 19 contains pure water 20 for dilution.

[0105] In this embodiment, the multi-channel droplet quantitative measuring device first quantitatively draws 10 nL of the drug solution from the po...

Embodiment 3

[0108] This embodiment is a highly integrated and modified version of the present invention.

[0109] Such as Figure 4 As shown, in this embodiment, the pressure source and pressure control system 1 is composed of an air compressor, a vacuum pump and a servo air pressure controller. The compressed air and vacuum required by the servo air pressure controller are provided by the air compressor and the vacuum pump respectively. By adopting the servo air pressure controller, the pressure source and the pressure control system 1 can generate continuously adjustable air pressure of -0.1MPa-0.6MPa. The pressure source and the pressure control system 1 are finally controlled by a computer program.

[0110] In this embodiment, the working medium reservoir 3 , the fluid damper 4 , and the sampling probe 7 are integrated into a microfluidic chip 21 . The working medium liquid reservoir 3 is connected with the pressure source and the pressure control system through the air pressure in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com