Synthetic method of In2O3 particles/In2O3 nanobelts and obtained product

A synthesis method and nanobelt technology, applied in gallium/indium/thallium compounds, nanotechnology, nanotechnology, etc., can solve problems such as complex chemical kinetic reactions, achieve good shape uniformity and repeatability, and optimize process parameters , the effect of controllable parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1.1 Mix 0.0058 g of ethyl cellulose, 0.0022 g of dicyandiamide, 0.4514 g of indium chloride (InCl 3 ) and 0.7026 g of PVP were dissolved in a mixed solvent consisting of 4 mL of DMF, 1 mL of ethanol and 20 μL of 1,3,5-trimethylbenzene, and stirred until transparent to obtain a precursor spinning solution;

[0026] 1.2 The precursor fiber was obtained by electrospinning the precursor spinning solution. The spinning parameters were: positive voltage 18 KV, negative voltage 0.5 KV, receiving distance 18 cm, and injector advance speed 0.002 mm / s;

[0027] 1.3 Place the precursor fiber in the muffle furnace, raise the temperature from room temperature to 500 °C at a rate of 2 °C / min in the air atmosphere, and keep it warm for 2 h. After the sample is cooled with the furnace, In 2 o 3 Particles / In 2 o 3 nanobelt.

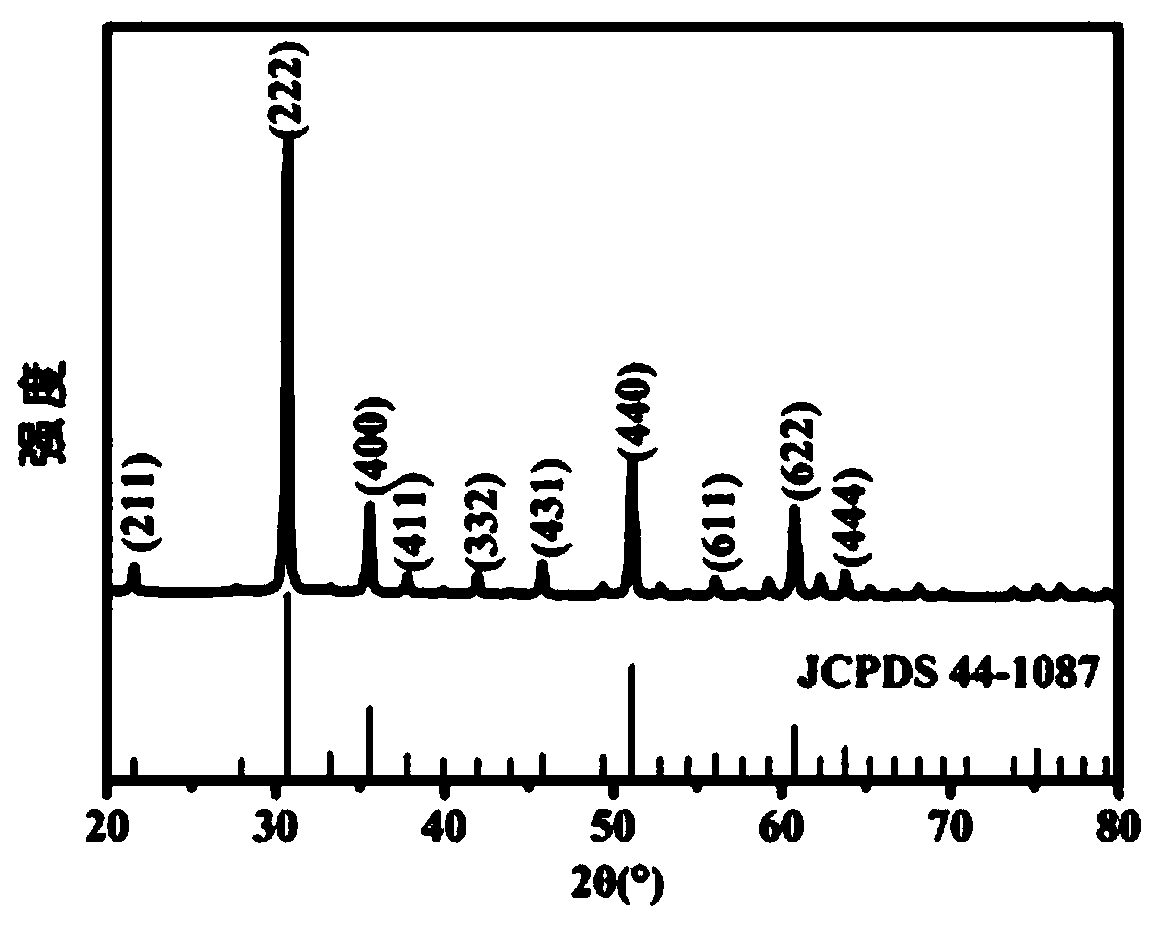

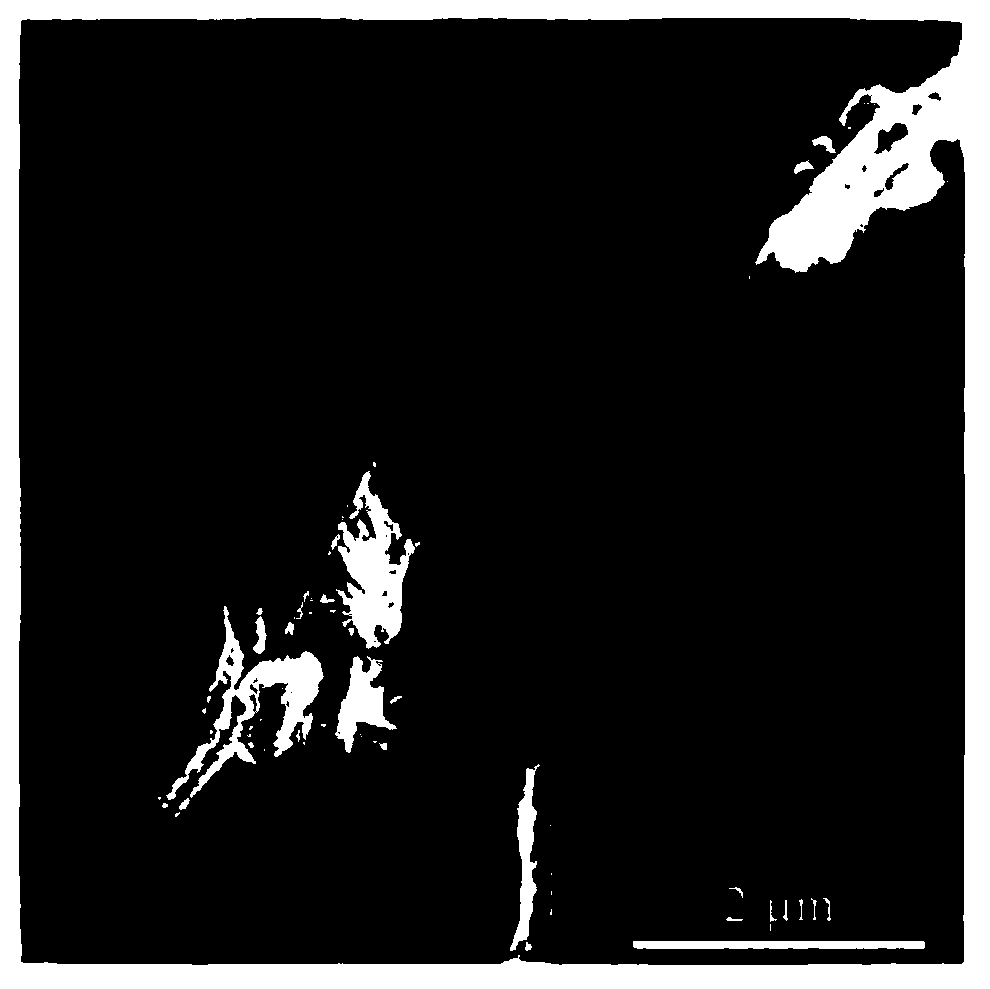

[0028] The XRD result of the product is as follows Figure 1 As shown, it can be seen from the figure that all the diffraction peaks are consistent with the s...

Embodiment 2

[0030] 2.1 Mix 0.0168 g of dicyandiamide, 0.0201 g of ethyl cellulose, and 0.3611 g of InCl 3 and 0.5427 g of PVP were dissolved in a mixed solvent composed of 4 mL of DMF, 1 mL of ethanol and 15 μL of 1,3,5-trimethylbenzene, and stirred until transparent to obtain a precursor spinning solution;

[0031] 2.2 The precursor fiber was obtained by electrospinning the precursor spinning solution. The spinning parameters were: positive voltage 17 KV, negative voltage 0.5 KV, receiving distance 17 cm, and injector advance speed 0.001 mm / s.

[0032] 2.3 Place the precursor fiber in the muffle furnace, raise the temperature from room temperature to 550 °C at a rate of 3 °C / min in the air atmosphere, and keep it for 3 h. After the sample is cooled with the furnace, In 2 o 3 Particles / In 2 o 3 nanobelt. Among them, In 2 o 3 The average diameter of the nanoribbons is 450-480 nm, the average thickness is 45-50 nm, In 2 o 3 The average size of the particles is 0.8-0.9 μm.

Embodiment 3

[0034] 3.1 Mix 0.0140 g of ethyl cellulose, 0.0038 g of dicyandiamide, and 0.6432 g of InCl 3 and 1.1098 g of PVP were dissolved in a mixed solvent composed of 4 mL of DMF, 1 mL of ethanol and 20 μL of 1,3,5-trimethylbenzene, and stirred until transparent to obtain a precursor spinning solution;

[0035] 3.2 The precursor fiber was obtained by electrospinning the precursor spinning solution. The spinning parameters were: positive voltage 17 KV, negative voltage 0.5 KV, receiving distance 17 cm, and advancing speed 0.003 mm / s;

[0036] 3.3 Place the obtained precursor fiber in a muffle furnace, raise the temperature from room temperature to 550 °C at a rate of 2 °C / min in an air atmosphere, and keep it for 4 h. After the sample is cooled with the furnace, In 2 o 3 Particles / In 2 o 3 nanobelt. Among them, In 2 o 3 The average diameter of the nanoribbons is 410-440 nm, the average thickness is 38-43 nm, In 2 o 3 The average size of the particles is 0.6-0.8 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com