Refining method for removing trace aldehyde group in 1,3-propylene glycol

A purification method and technology of propylene glycol, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of slow reaction rate, poor effect, and high resin cost, and achieve easy separation, obvious cost advantages, and operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

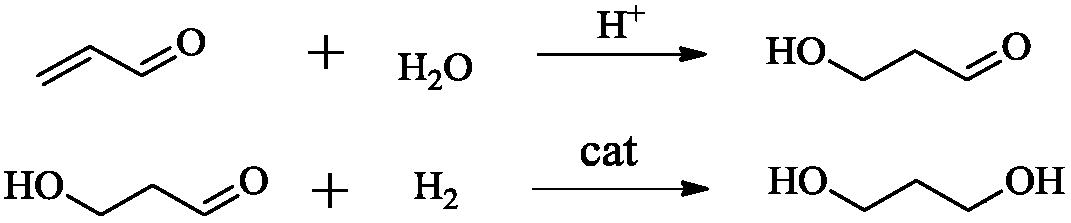

Problems solved by technology

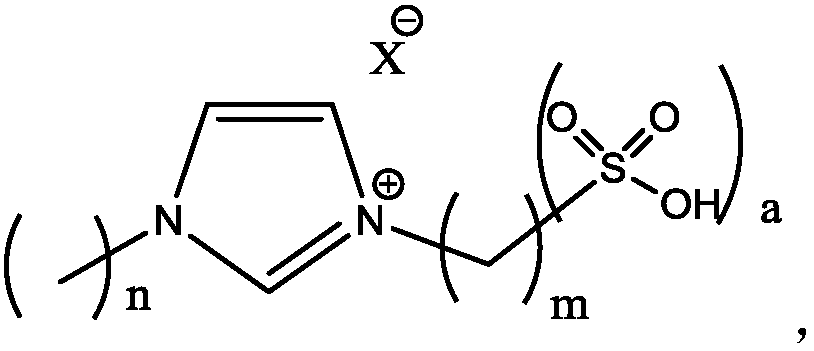

Method used

Image

Examples

Embodiment 1-16

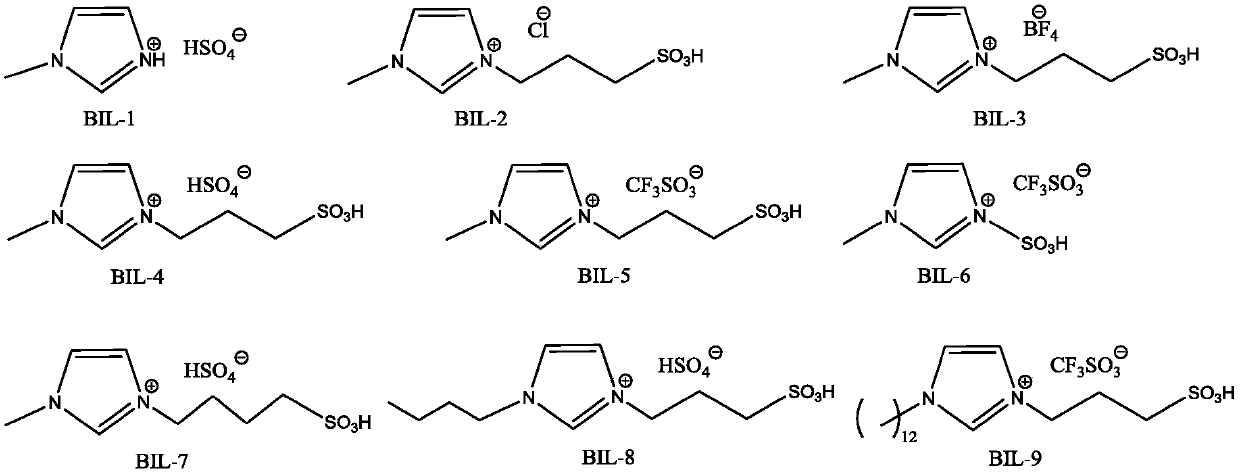

[0059] Preheat the 1,3-propanediol solution containing aldehyde-based impurities to 60-140°C, inject 250mL into the stirred tank reactor with a pump, add sulfonic acid ionic liquid to a concentration of 0.1-10wt%, and perform dealdehyde reaction , Reaction time 0.5-6h. The treated 1,3-propanediol is distilled, the number of plates is 16-40, the temperature of the tower bottom is 138-155°C, the reflux ratio is 2:1-15:1, and the pressure at the top of the tower is 1-10kPa. The specific operating conditions and treatment effects are shown in the table below. The aldehyde group content in the raw material before the dealdehyde treatment is 792ppm.

[0060] Table 1 The dealdehyde process and effect of different sulfonic acid ionic liquids

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com