Method of utilizing waste and old cathode material to prepare demercuration catalyst and application of demercuration catalyst

A cathode material and catalyst technology, applied in the field of preparation of mercury removal catalysts, can solve the problems of limited wide application and high production cost, and achieve the effects of improving economic benefits, low raw material costs, and realizing resource recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this example, the method for preparing a mercury removal catalyst using waste positive electrode materials, the waste and old positive electrode materials in this example are nickel-cobalt-manganese ternary positive electrode materials, and the molar ratio of the three is 1:1:1, including the following steps :

[0031] (1) Prepare 100mL of NaOH solution with a pH of 11, add 30g of waste cathode materials into the prepared solution, stir at 500r / min and react at 50°C for 1h. After the reaction, the slurry is filtered and washed, and dried at 60°C More than 10h, the dealuminated positive electrode material is obtained;

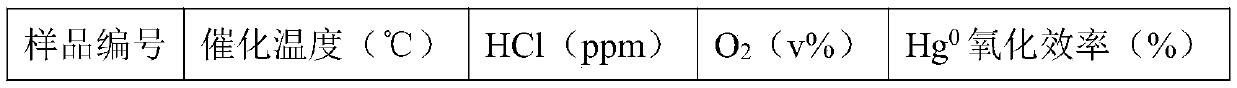

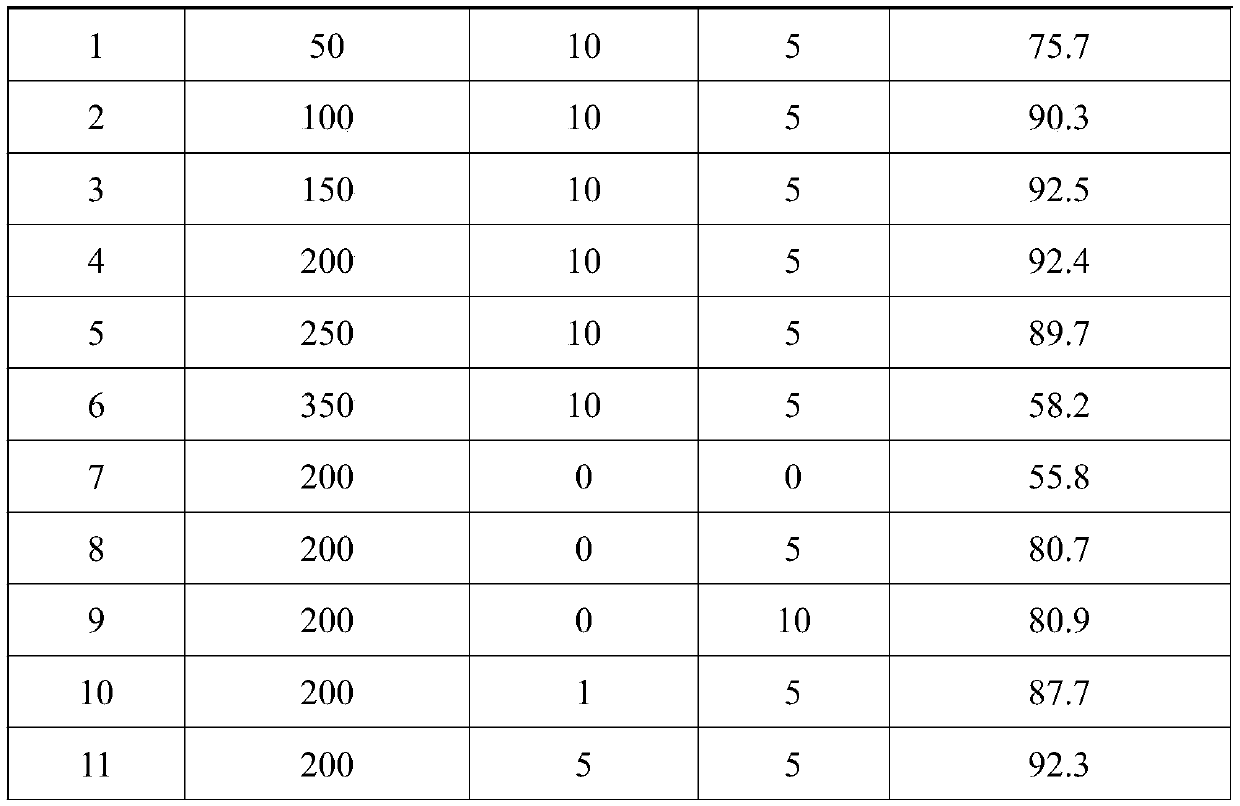

[0032] (2) Place the dealuminated cathode material in a tube furnace and feed high-purity N at a flow rate of 1L / min 2 As a protective gas, then heated to different temperatures at a heating rate of 5°C / min (see Table 1 below for specific temperatures), and after holding for 30 minutes, composite carbon catalysts of different metal oxides were obtaine...

Embodiment 2

[0039] In this example, the method for preparing a mercury removal catalyst using waste positive electrode materials, the waste and old positive electrode materials in this example are nickel-cobalt-manganese ternary positive electrode materials, and the molar ratio of the three is 1:1:1, including the following steps :

[0040] (1) Prepare 100mL of NaOH solution with a pH of 11, add 30g of waste cathode materials into the prepared solution, stir at 500r / min and react at 50°C for 1h. After the reaction, the slurry is filtered and washed, and dried at 60°C More than 10h, the dealuminated positive electrode material is obtained;

[0041] (2) Place the obtained dealuminated cathode material in a tube furnace and feed high-purity N at a flow rate of 1L / min 2 As a protective gas, then heated to 700°C at a heating rate of 5°C / min, and after holding for 30 minutes, a metal oxide composite carbon catalyst was obtained;

[0042] (3) Place the above-mentioned prepared metal oxide comp...

Embodiment 3

[0048] In this example, the method for preparing a mercury removal catalyst using waste positive electrode materials, the waste and old positive electrode materials in this example are nickel-cobalt-manganese ternary positive electrode materials, and the molar ratio of the three is 1:1:1, including the following steps :

[0049] (1) Prepare 100mL of NaOH solution with a pH of 11, add 30g of waste cathode materials into the prepared solution, stir at 500r / min and react at 50°C for 1h. After the reaction, the slurry is filtered and washed, and dried at 60°C More than 10h, the dealuminated positive electrode material is obtained;

[0050] (2) Place the obtained dealuminated cathode material in a tube furnace and feed high-purity N at a flow rate of 1L / min 2 As a protective gas, then heated to 700°C at a heating rate of 5°C / min, and after holding for 30 minutes, a metal oxide composite carbon catalyst was obtained;

[0051] (3) Place the above-mentioned prepared metal oxide comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com