Prime coating liquid suitable for aqueous pigment ink printed non-absorptive printing medium, and preparation method and applications thereof

A printing medium and water-based pigment technology, which is applied in the direction of protein coating, primer, coating, etc., can solve the problems of unsatisfactory printing effect, water-based pigment ink cannot be spread and dried, and poor friction resistance of the finished product, so as to improve the resolution High efficiency, improved drying speed and color fixing ability, good ink absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

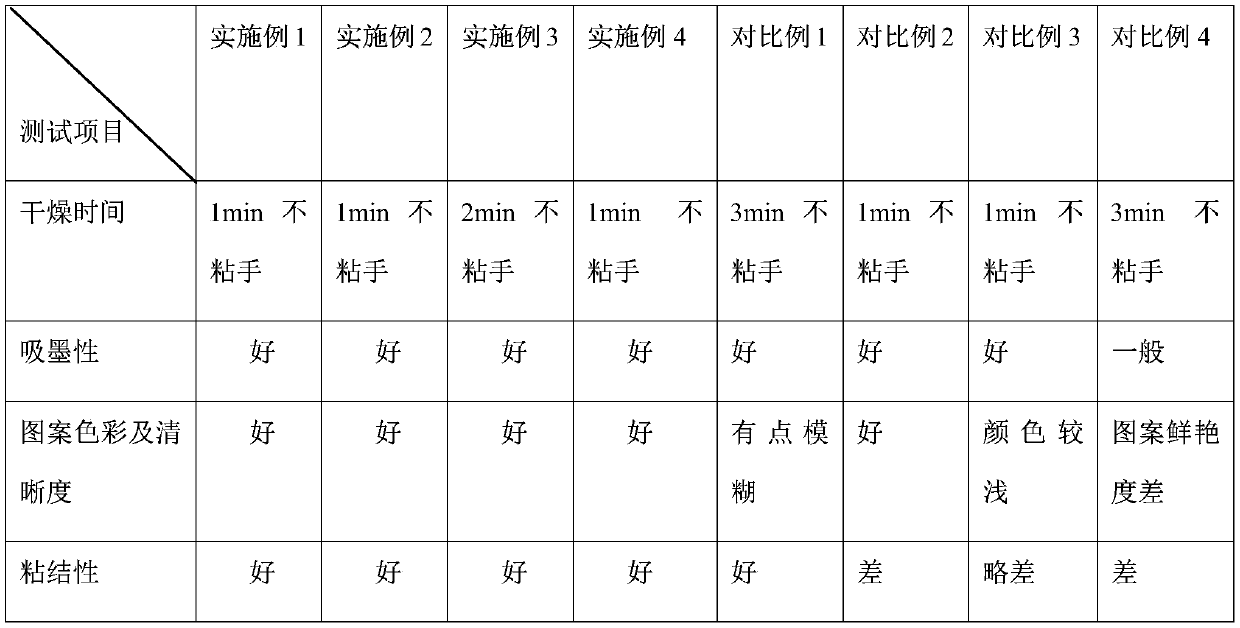

Examples

Embodiment 1

[0021] A primer liquid suitable for printing non-absorbent printing media with water-based pigment inkjet ink, which is made of the following components by weight percentage: nano-silica emulsion: 20%, polyvinyl alcohol: 5%, cationic polyurethane Emulsion: 15%, cationic ethylene-vinyl acetate copolymer emulsion: 15%, triethylbenzyl ammonium chloride: 8%, Tego 270: 0.5%, Surfynol DF-104E: 1%, F-046: 1%, Deionized water: the remaining amount. The preparation process of the primer solution includes: after deionized water is heated to 70°C, polyvinyl alcohol is added to the water in 4 times at a stirring speed of 800r / min; after the polyvinyl alcohol is completely dissolved, it is cooled to room temperature , and add Digo 270, Surfynol DF-104E, F-046, nano-silica emulsion to it at a stirring speed of 1200r / min and stir evenly, then add cationic polyurethane emulsion, cationic ethylene-vinyl acetate copolymer The emulsion and triethylbenzyl ammonium chloride were continuously stir...

Embodiment 2

[0024] A primer liquid suitable for printing non-absorbent printing media with water-based pigment inkjet ink, which is made of the following components by weight percentage: nano-alumina: 15%, gelatin: 10%, cationic acrylic resin emulsion: 10% %, cationic ethylene-vinyl acetate copolymer emulsion: 15%, dodecyl dimethyl benzyl ammonium bromide: 12%, Tego 280: 0.5%, Surfynol DF-420: 1%, BIT: 1%, Deionized water: the remaining amount. The preparation process of the primer solution includes: heating deionized water to 80°C, and adding gelatin to the water in batches for 3 times at a stirring speed of 800r / min; Add Tego 280, Surfynol DF-420, BIT and nano-alumina in turn at a stirring speed of / min and stir evenly, then add cationic acrylic resin emulsion, cationic ethylene-vinyl acetate copolymer emulsion and dodecane Base dimethyl benzyl ammonium bromide and continue to stir until completely uniform to obtain the water-based primer.

[0025]After the primer liquid prepared in t...

Embodiment 3

[0027] A primer liquid suitable for printing non-absorbent printing media with water-based pigment inkjet ink, which is made of the following components by weight percentage: nano-titanium dioxide: 50%, polyvinylpyrrolidone: 10%, cationic polyurethane resin emulsion: 15%, trimethylcetylammonium hydroxide: 6%, Dow X-405: 0.1%, Surfynol DF-110L: 0.1%, ProxelGXL: 0.3%, deionized water: the balance. The preparation process of the primer solution is similar to that of Example 1, and will not be repeated here.

[0028] After the primer solution prepared in this example is evenly applied to the polyurethane substrate by wiping, it is dried under microwave for 3 minutes, and then any water-based pigment ink commonly used in the art can be used to coat the primer solution on the polyurethane substrate. The finished product is obtained after inkjet printing on a layer of polyurethane substrate and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com