Nickel ion adsorbent and preparation method thereof

An adsorbent, nickel ion technology, applied in chemical instruments and methods, adsorbed water/sewage treatment, other chemical processes, etc., can solve the problems of poor adsorption effect, high price, low adsorption capacity, etc. O element content, effect of increased ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

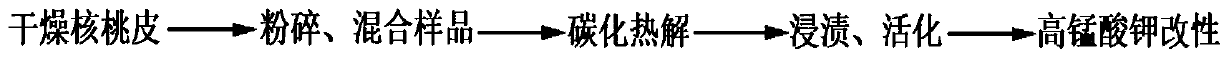

[0042] Such as figure 1 Shown, the preparation method of the nickel ion adsorbent of the present embodiment comprises the following steps:

[0043] (1) Dry walnut green skin with a blast drying box, wherein the temperature of the blast drying box is 65° C. to obtain dry walnut skin.

[0044] (2) Grind and mix dry walnut skin and ammonium oxalate at a mass ratio of 3:7 to obtain a mixed sample, wherein the particle size of the mixed sample is less than 180 mesh.

[0045] (3) Carbonize and pyrolyze the mixed sample: put the mixed sample into a corundum boat, put the corundum boat into a tube furnace, and pass in an inert gas. The heating procedure for pyrolysis and carbonization is as follows: the initial temperature is 25°C, The heating rate is 4°C / min, the final temperature is 530°C, the holding time is 360min, and then the temperature is naturally lowered to obtain the initial adsorbent. (

[0046] (4) Initial adsorbent impregnation and activation: The specific process of ...

Embodiment 2

[0050] In this example, step (4) of initial adsorbent impregnation and activation in Example 1 is removed, and other implementations are the same as in Example 1.

[0051] The nickel ion adsorbent obtained in this example is named sample2.

Embodiment 3

[0053] In this embodiment, step (5) potassium permanganate modification in embodiment 1 is removed, and other embodiments are the same as embodiment 1.

[0054] The nickel ion adsorbent obtained in this example is named sample3.

[0055] analyse and compare:

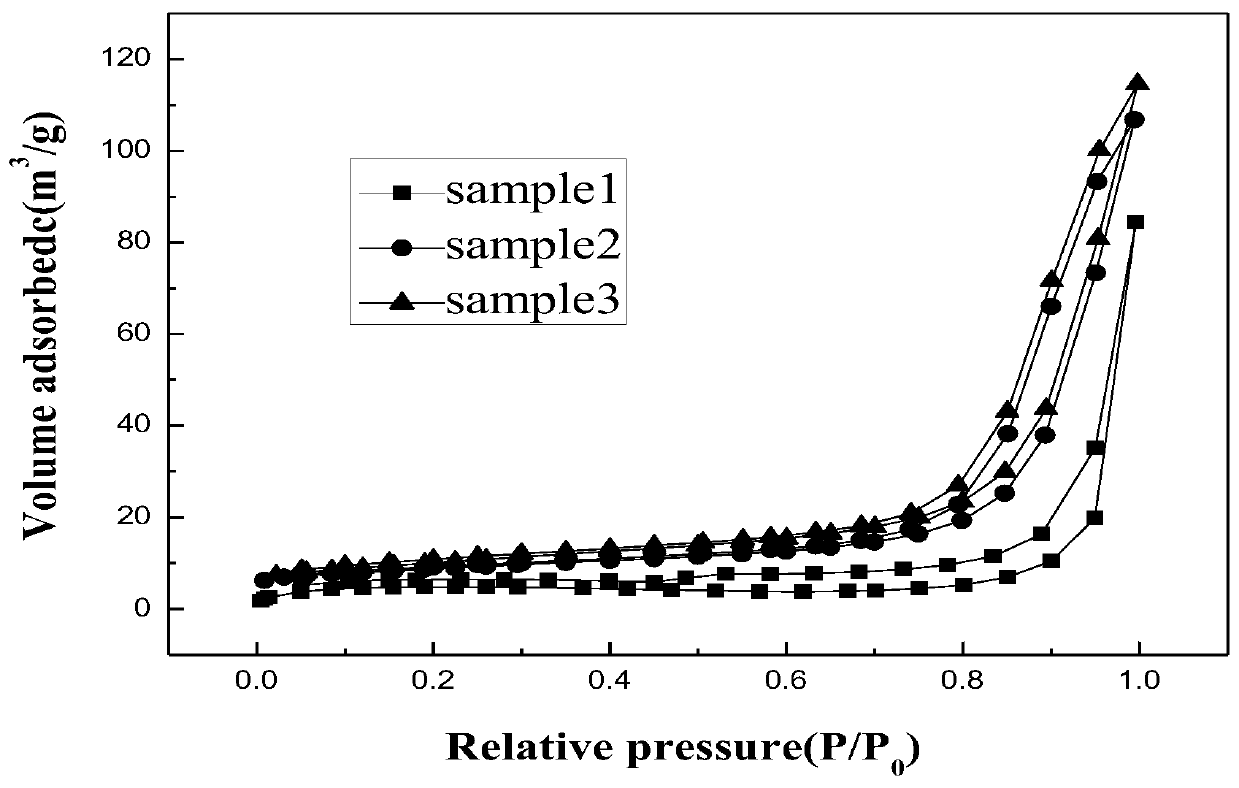

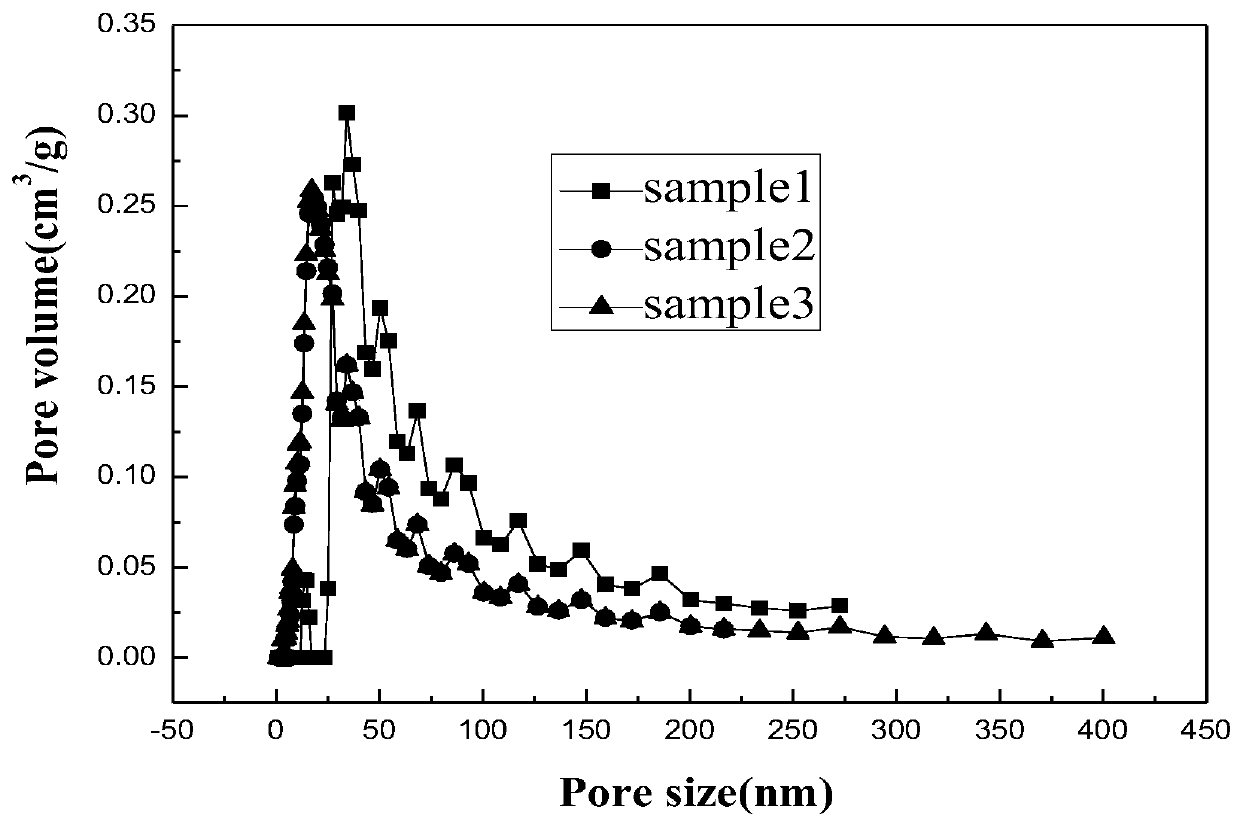

[0056] 1. Nitrogen adsorption and desorption test

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com