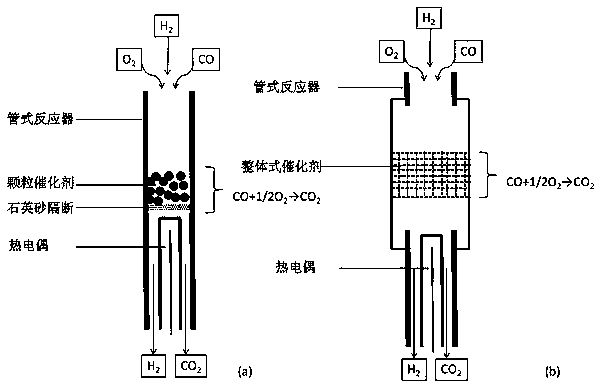

Monolithic catalyst for preferentially oxidizing CO under hydrogen-rich condition, and preparation method thereof

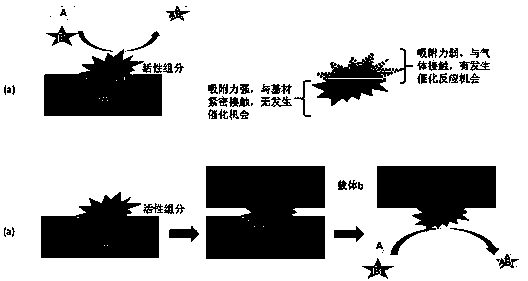

A catalyst and integrated technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems affecting catalyst performance, etc., to avoid catalyst deactivation, Good catalytic performance and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

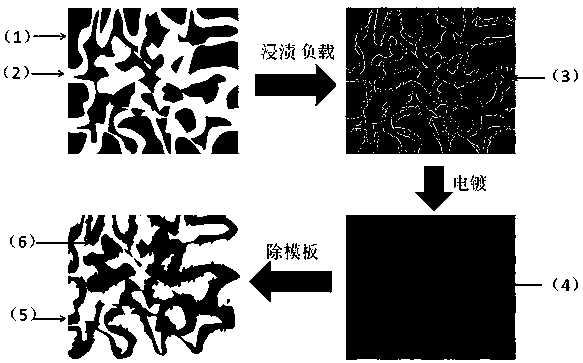

[0041] Regarding the preparation method of porous metal, in the prior art, such as JPH07150270 A, a high-strength porous metal body is proposed, which is obtained by adding oxides, carbides, nitrogen and Coatings of reinforcement particles such as compounds, etc., are coated on the surface of the skeleton of a three-dimensional network resin having continuous pores, and a metal plating layer of Ni alloy or Cu alloy is further formed on the coating film of the coating, and then, heat-treated. Particles are obtained by dispersing the metal coating. WO2013099532 proposes a method for producing a porous body in which, when conducting a conductive treatment on the surface of a resin forming body having a three-dimensional network structure, carbon paint is mixed with metal powder for coating, and then the desired metal is plated , heat-treated to obtain a homogeneous alloy porous body. US2018030607 discloses a method for manufacturing a nickel alloy porous body, including: coating...

Embodiment 1

[0044] The catalyst preparation process is as follows:

[0045] (a) Preparing polystyrene (1) macroporous polymer foam, the pore diameter of the polystyrene channel 2 is 20-40 μm. ;

[0046] (b) Configure an aqueous solution of metal active components, the active component is chloroplatinic acid-nitrosyl ruthenium nitrate-graphene aqueous solution 3, wherein the molar ratio Pt:Ru=1:(1~1.5), the active component 2 ~9wt.%, the content of graphene is 10~30%;

[0047] (c) Use a vacuum pump to carry out vacuum filling until no bubbles emerge on the surface of the polymer foam immersed in the aqueous solution of the metal active component, then dry in an oven, repeat filling and drying, and the number of repetitions is 4 times, and the active component Pt- Ru-graphene is filled to the surface of polystyrene polymer foam channels;

[0048] (d) With the polymer foam filled in the step (c) as the negative electrode, immersed in the nickel electroplating solution 4, carry out electro...

Embodiment 2

[0052] The catalyst preparation process is as follows:

[0053] (a) Preparing polystyrene (1) macroporous polymer foam, the pore diameter of the polystyrene channel 2 is 20-40 μm. ;

[0054] (b) Configure an aqueous solution of metal active components, the active component being chloroplatinic acid-nitrosyl ruthenium nitrate-graphene aqueous solution 3, wherein the molar ratio Pt:Ru=1:1.25, active component 5wt.%, graphite The content of alkenes is 20%;

[0055] (c) Use a vacuum pump to carry out vacuum filling until no bubbles emerge on the surface of the polymer foam immersed in the aqueous solution of the metal active component, then dry in an oven, repeat filling and drying, and the number of repetitions is 4 times, and the active component Pt- Ru-graphene is filled to the surface of polystyrene polymer foam channels;

[0056] (d) With the polymer foam filled in the step (c) as the negative electrode, immersed in the nickel electroplating solution 4, carry out electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com