Process and system for desulfurizing fume by two-stage liquid column spray

A desulfurization system and flue gas technology, applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of large changes in flue gas volume, poor adaptability to flue gas load regulation, and difficulty in flue gas adaptation. Small footprint, compact structure, obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

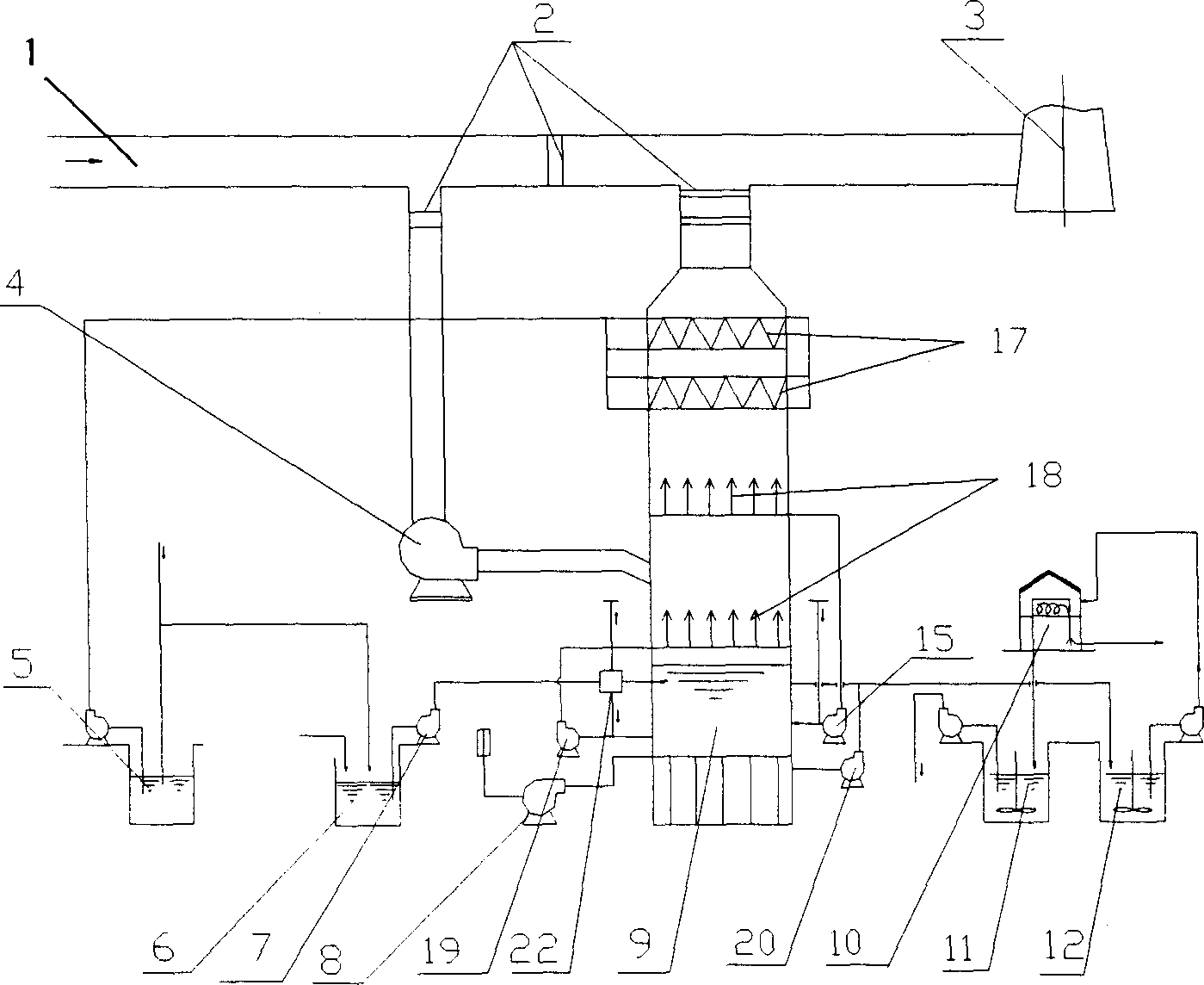

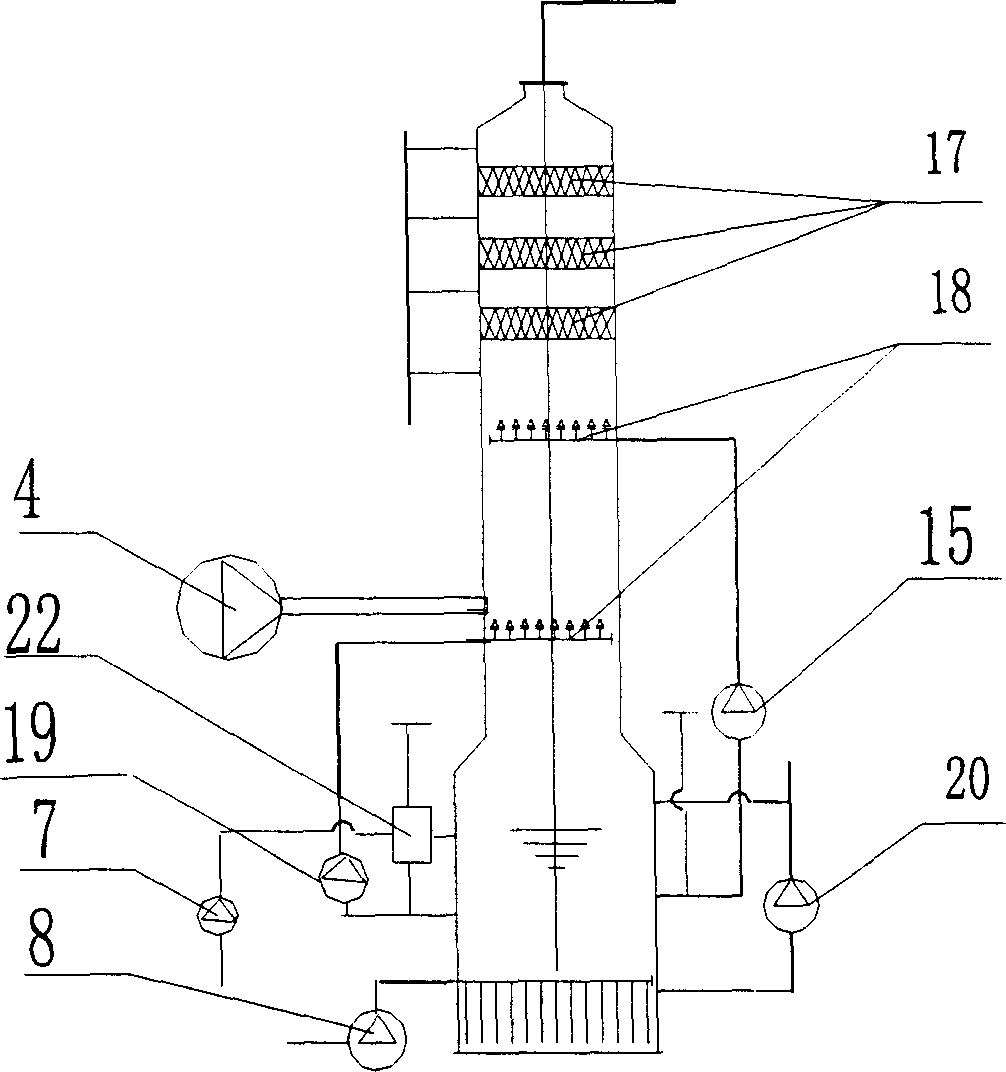

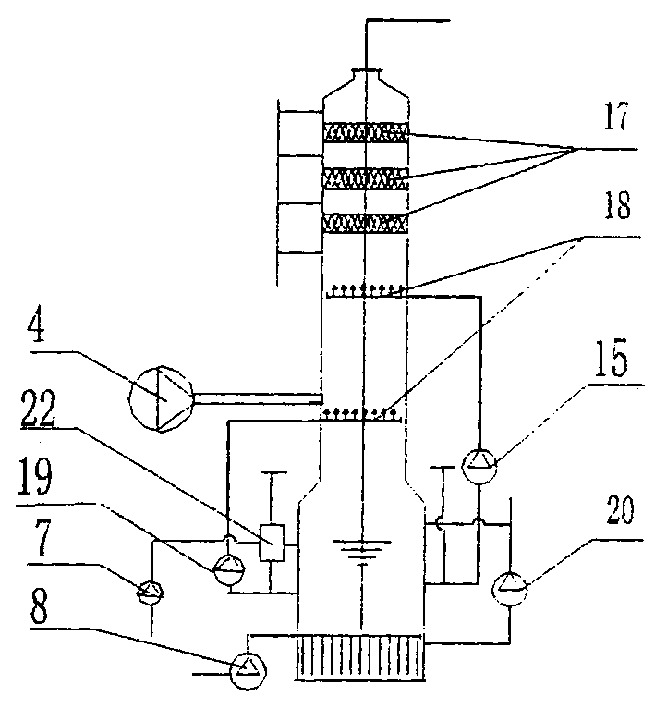

[0015] The system is mainly composed of a flue gas delivery system, a desulfurizer slurry supply system, a reaction tower, an industrial water supply and demister system, and a gypsum treatment system. The flue gas delivery system includes a flue 1, a flue gas valve 2 and a blower 4; The desulfurizing agent slurry supply system is composed of a lye pool 6, a slurry pump 7 and a circulating pump. The reaction tower includes a desulfurization reaction zone and a desulfurization by-product oxidation reaction zone, which includes a water pipe, a mist eliminator 17, a flue gas inlet, Flue gas outlet, liquid column injection system 18 and blast system 8, etc., liquid column injection system 18 is composed of upper and lower two-stage desulfurizer slurry injection devices and two slurry circulation pumps 15 and 19 arranged in the desulfurization reaction zone . Simultaneously, this system has also installed a pH adjustment device 22 additionally at the outlet of the slurry delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com