Method and device for continuously preparing chloropivaloyl chloride by using micro-channel

A technology of chloropivaloyl chloride and pivaloyl chloride, applied in separation methods, carboxylate preparation, chemical instruments and methods, etc., can solve the problem of poor separation effect of impurities in the rectifying section, poor product quality stability, and poor control of reaction conditions. and other problems, to achieve the effect of enhancing the photochlorination reaction efficiency, less impurities, and short reaction time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

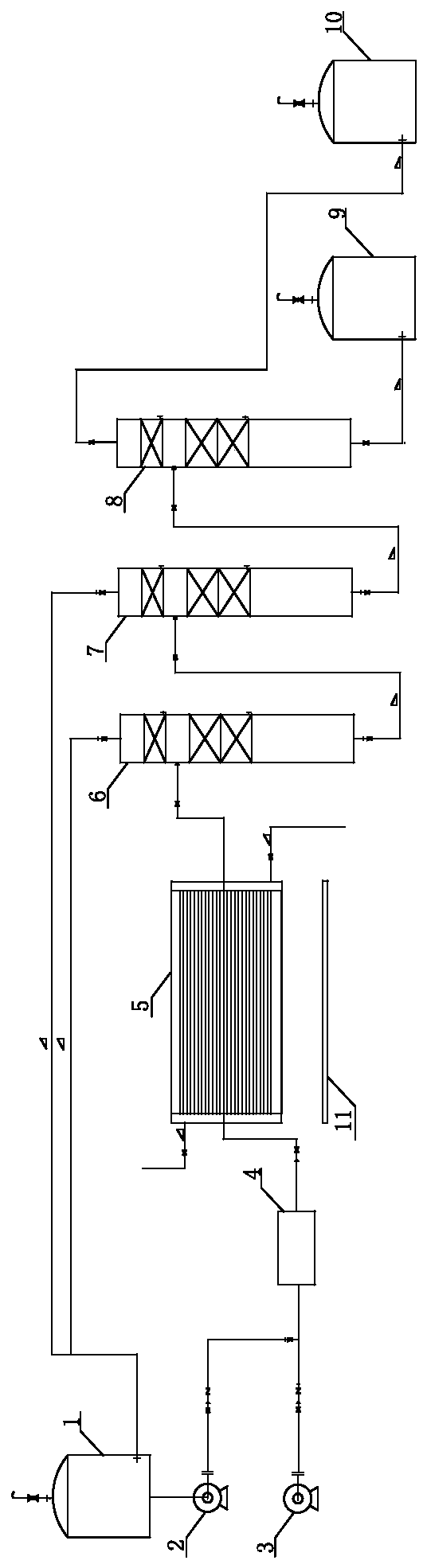

Image

Examples

Embodiment 1

[0033] The pivaloyl chloride in the pivaloyl chloride storage tank is mixed with the pivaloyl chloride delivery pump at a flow rate of 500kg / h and the chlorine gas is mixed with the chlorine gas delivery pump at a flow rate of 278kg / h at the same time into the pipeline before the preprocessor, and enters the inner wall with MnS- The pretreatment of the ZnS composite catalyst pretreatment, the preprocessor controls the normal pressure, the temperature is 60 ℃, and the reaction residence time is 10s; the thickness of the MnS-ZnS composite catalyst on the inner wall of the preconditioner is 4.5mm; after that, it enters the microchannel photochlorination In the reactor, under the condition of ultraviolet light irradiation with a wavelength of 350nm, the reaction temperature is controlled at 75°C and the reaction residence time is 30s to obtain the chloropivaloyl chloride reaction liquid, and then the chloropivaloyl chloride reaction liquid enters the front distillation tower in a va...

Embodiment 2

[0035] The pivaloyl chloride in the pivaloyl chloride storage tank is mixed with the pivaloyl chloride delivery pump at a flow rate of 500kg / h and the chlorine gas is mixed with the chlorine gas delivery pump at a flow rate of 294kg / h at the same time into the pipeline before the preprocessor, and enters the inner wall with MnS- The pretreatment of the ZnS composite catalyst pretreatment, the preprocessor controls the normal pressure, the temperature is 50 ℃, and the reaction residence time is 15s; the thickness of the MnS-ZnS composite catalyst on the inner wall of the preconditioner is 5.0mm; after that, it enters the microchannel photochlorination In the reactor, under the condition of ultraviolet light irradiation with a wavelength of 340nm, the reaction temperature is controlled at 60°C and the reaction residence time is 30s to obtain the chloropivaloyl chloride reaction liquid, and then the chloropivaloyl chloride reaction liquid enters the front distillation tower in a va...

Embodiment 3

[0037] The pivaloyl chloride in the pivaloyl chloride storage tank is mixed with the pivaloyl chloride delivery pump at a flow rate of 500kg / h and the chlorine gas is mixed with the chlorine gas delivery pump at a flow rate of 250kg / h into the pipeline before the preprocessor, and enters the inner wall with MnS- The pretreatment of the ZnS composite catalyst pretreatment, the preconditioner controls the normal pressure, the temperature is 35 ℃, and the reaction residence time is 10s; the thickness of the MnS-ZnS composite catalyst on the inner wall of the preconditioner is 2.5mm; after that, it enters the microchannel photochlorination In the reactor, under the condition of ultraviolet light irradiation with a wavelength of 360nm, the reaction temperature is controlled at 80°C and the reaction residence time is 30s to obtain the chloropivaloyl chloride reaction liquid, and then the chloropivaloyl chloride reaction liquid enters the front distillation tower in a vacuum Control t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com