Halogen-free phosphorus-nitrogen additive-type flame retardant and preparation method thereof

A halogen-free phosphorus-nitrogen, additive-type technology, applied in the field of halogen-free flame retardants, can solve the problems of poor thermal stability, difficult processing, easy exudation, etc., and achieves the effects of high synthesis efficiency, low yield and difficult hydrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a preparation method of a halogen-free phosphorus-nitrogen additive flame retardant, the steps comprising:

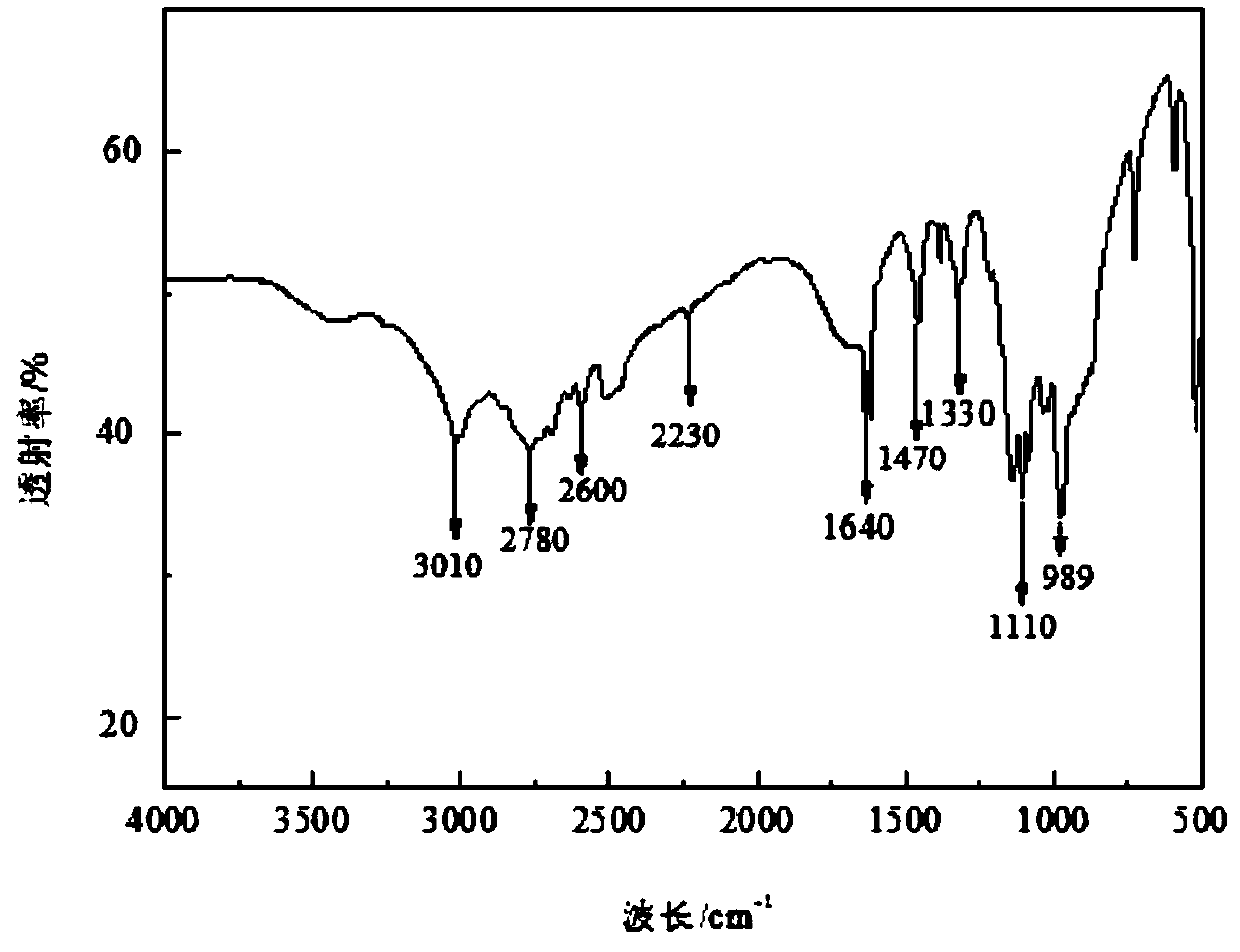

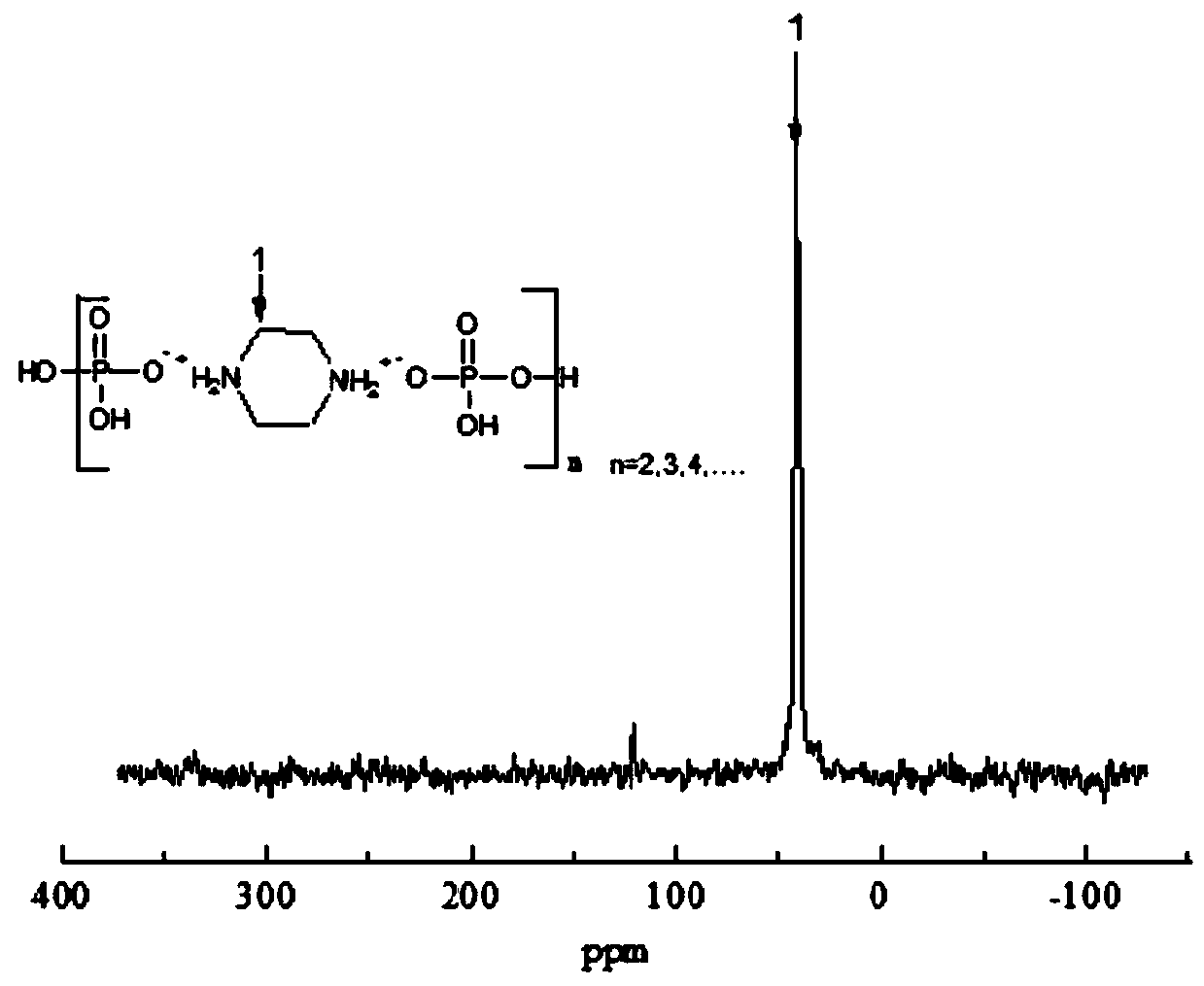

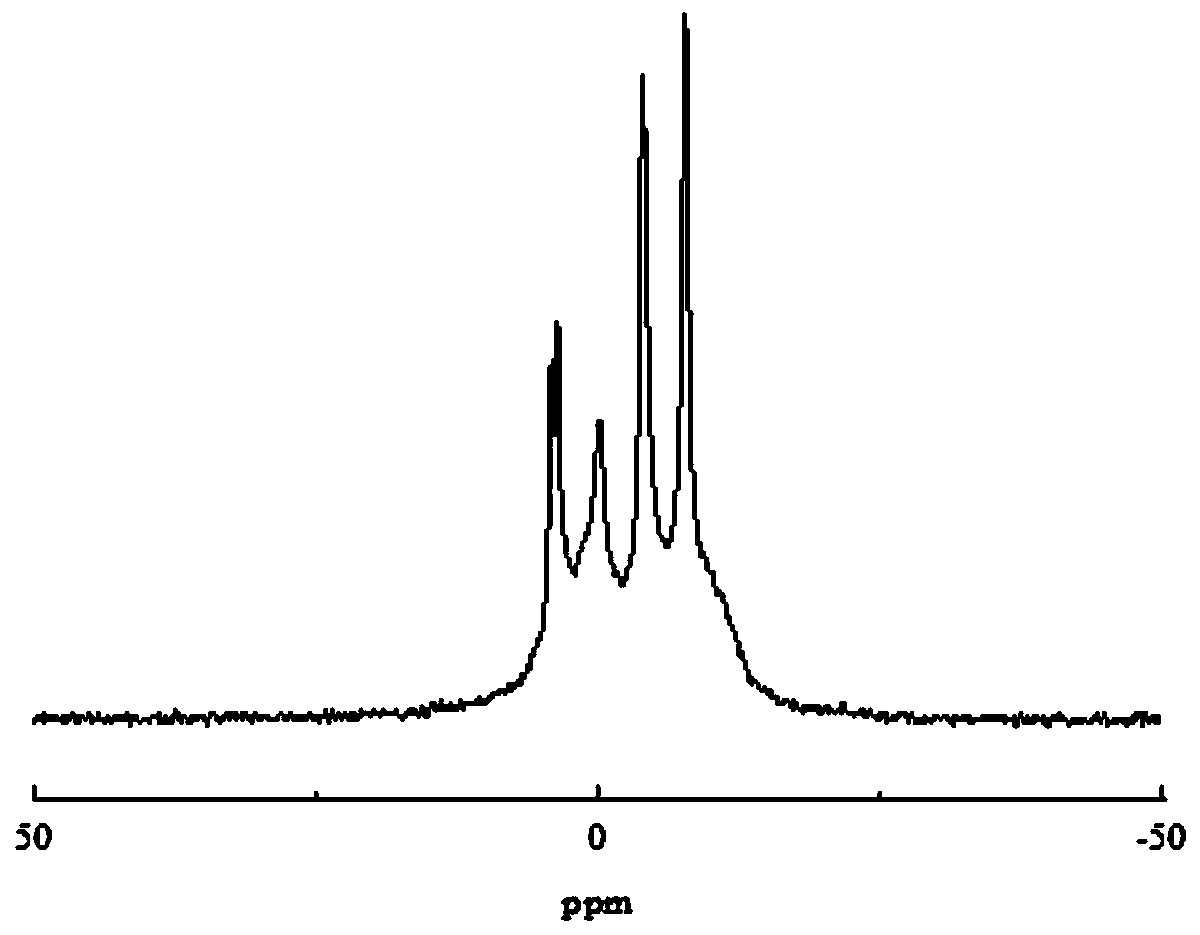

[0032] (1) Preparation of intermediate piperazine diphosphate

[0033] A nitrogen-passing device, a mechanical stirrer, a spherical condenser, a thermometer and a constant-pressure dropping funnel were installed on a 500 mL five-necked round-bottomed flask (all glass instruments were thoroughly washed and dried with deionized water before use). Under the condition of nitrogen, pour 115.3 g of phosphoric acid solution with a concentration of 98% into the reaction device, and then put 43.1 g of anhydrous piperazine into a 250 mL beaker, stir with an appropriate amount of deionized water until completely dissolved, pour into constant In the dropping funnel, slowly dropwise into the phosphoric acid solution in the reaction vessel. After the dropwise addition of the anhydrous piperazine solution, the reaction temperature of the system was rais...

Embodiment 2

[0039] This embodiment provides a preparation method of a halogen-free phosphorus-nitrogen additive flame retardant, the steps comprising:

[0040] (1) Preparation of intermediate piperazine diphosphate

[0041] A nitrogen-passing device, a mechanical stirrer, a spherical condenser, a thermometer and a constant-pressure dropping funnel were installed on a 500 mL five-necked round-bottomed flask (all glass instruments were thoroughly washed and dried with deionized water before use). Under the condition of nitrogen, pour 98 g of phosphoric acid solution with a concentration of 85% into the reaction device, and then put 34.4 g of anhydrous piperazine into a 250 mL beaker, stir with an appropriate amount of deionized water until it is completely dissolved, pour it into a constant pressure In the dropping funnel, slowly added dropwise to the phosphoric acid solution in the reaction vessel. After the dropwise addition of the anhydrous piperazine solution, the reaction temperature o...

Embodiment 3

[0045] This embodiment provides a preparation method of a halogen-free phosphorus-nitrogen additive flame retardant, the steps comprising:

[0046] (1) Preparation of intermediate piperazine diphosphate

[0047] A nitrogen-passing device, a mechanical stirrer, a spherical condenser, a thermometer and a constant-pressure dropping funnel were installed on a 500 mL five-necked round-bottomed flask (all glass instruments were thoroughly washed and dried with deionized water before use). Under the condition of nitrogen, 98g phosphoric acid solution with a concentration of 98% was poured into the reaction device, and then 43.5g anhydrous piperazine was put into a 250mL beaker, stirred with an appropriate amount of deionized water until completely dissolved, poured into a constant pressure In the dropping funnel, slowly added dropwise to the phosphoric acid solution in the reaction vessel. After the dropwise addition of the anhydrous piperazine solution, the reaction temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com