Lubricating oil for methanol fuel engine, and preparation method thereof

A methanol fuel and engine technology, applied in the direction of lubricating composition, petroleum industry, etc., can solve problems such as inefficiency, emulsification, corrosion, etc., and achieve the effect of eliminating emulsification corrosion and coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

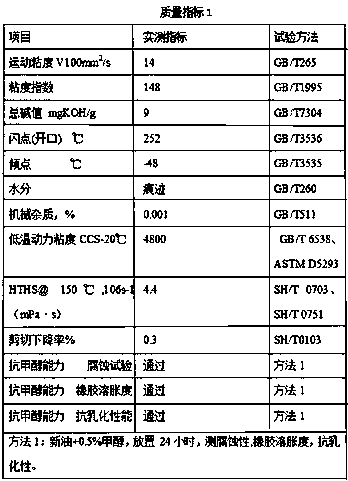

Embodiment 1

[0022] Example 1: A lubricating oil for a methanol fuel engine, prepare SpectraSyn Elite 4: 430kg, SpectraSyn Elite 10: 500kg, SpectraSyn Elite 600: 70kg, metal phenate: 10kg, dialkyldithiophosphoric acid and carboxylic acid Mixed zinc salt: 15kg, acid neutralizer: 30kg, mixed ashless dispersant: 80kg, rust inhibitor AR-CU: 3kg, aminothioester: 10kg, 2# compound antifoaming agent: 0.1kg, anti-emulsifier DL -32:0.5kg

[0023] Production method: (1), put low-viscosity metallocene polyalphaolefin, medium-viscosity metallocene polyalphaolefin, high-viscosity metallocene polyalphaolefin, 2# composite antifoaming agent, DL-32 anti-emulsifier into the reaction kettle, Raise the temperature to 65°C and stir for 45 minutes;

[0024] (2) Add metal phenate, dialkyl dithiophosphoric acid and carboxylic acid mixed zinc salt, acid neutralizer, mixed ashless dispersant, antirust agent AR-CU, aminothioester, add in sequence, and keep the temperature at 65 ℃, stirring for 90 minutes, and aft...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap