Neodymium-iron-boron magnet surface composite corrosion-resistant coating and preparation method thereof

A surface compounding, NdFeB technology, applied in the manufacture of permanent magnets, magnets, magnetic objects, etc., can solve the problems of reduced performance and life, complicated process, high cost, etc., to achieve extended service life, simple preparation process, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

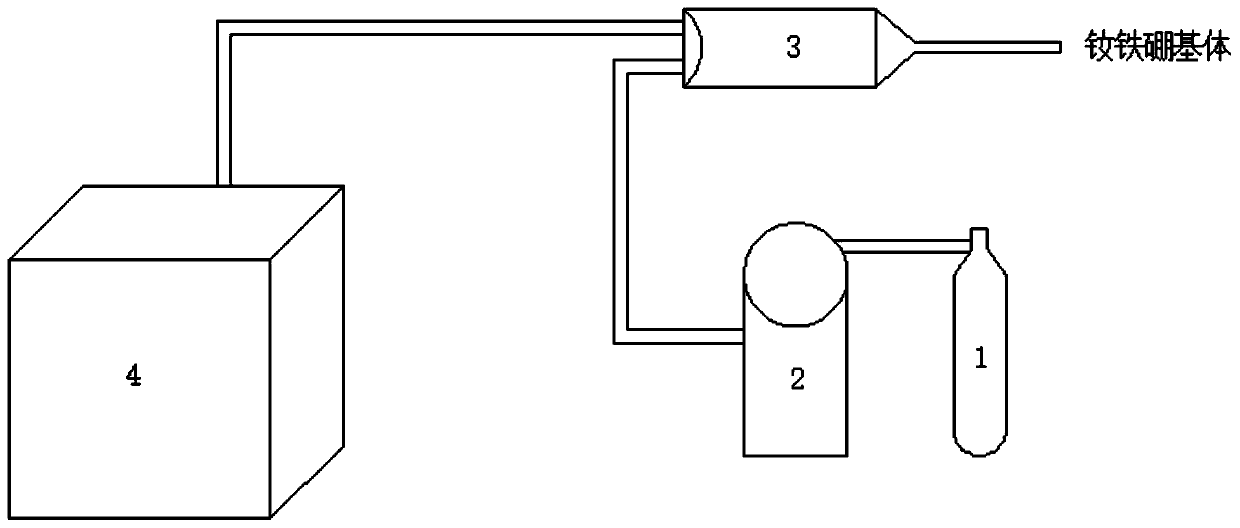

Method used

Image

Examples

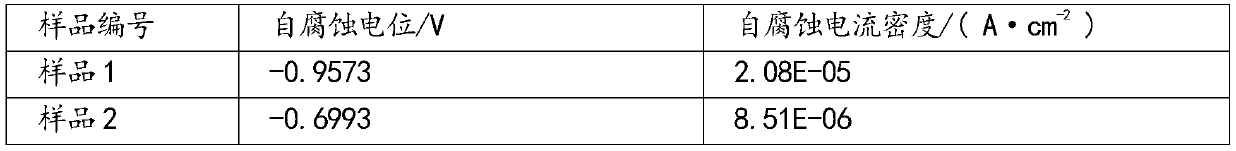

Embodiment 1

[0045] This embodiment prepares cold-sprayed aluminum-based corrosion-resistant coatings, that is, cold-sprays aluminum coatings on the surface of NdFeB magnets without passivation and sealing treatment; the specific preparation method includes the following steps:

[0046] (1) Surface treatment of NdFeB substrate: select N42 NdFeB substrate with a thickness of 5mm and a diameter of 25mm, perform sandblasting and degreasing treatment on the surface, and then perform ultrasonic cleaning with absolute ethanol, clean and dry Finally, seal it with a sample bag to avoid surface oxidation.

[0047] (2) Preparation and processing of aluminum powder: ①The aluminum ingot is melted into molten aluminum in the melting furnace; ②The molten aluminum is introduced into the atomization furnace, and when the temperature reaches 900-950°C, it is sprayed in the atomization chamber under the action of airflow and pressure Atomized into small droplets, the small droplets are cooled under the protec...

Embodiment 2

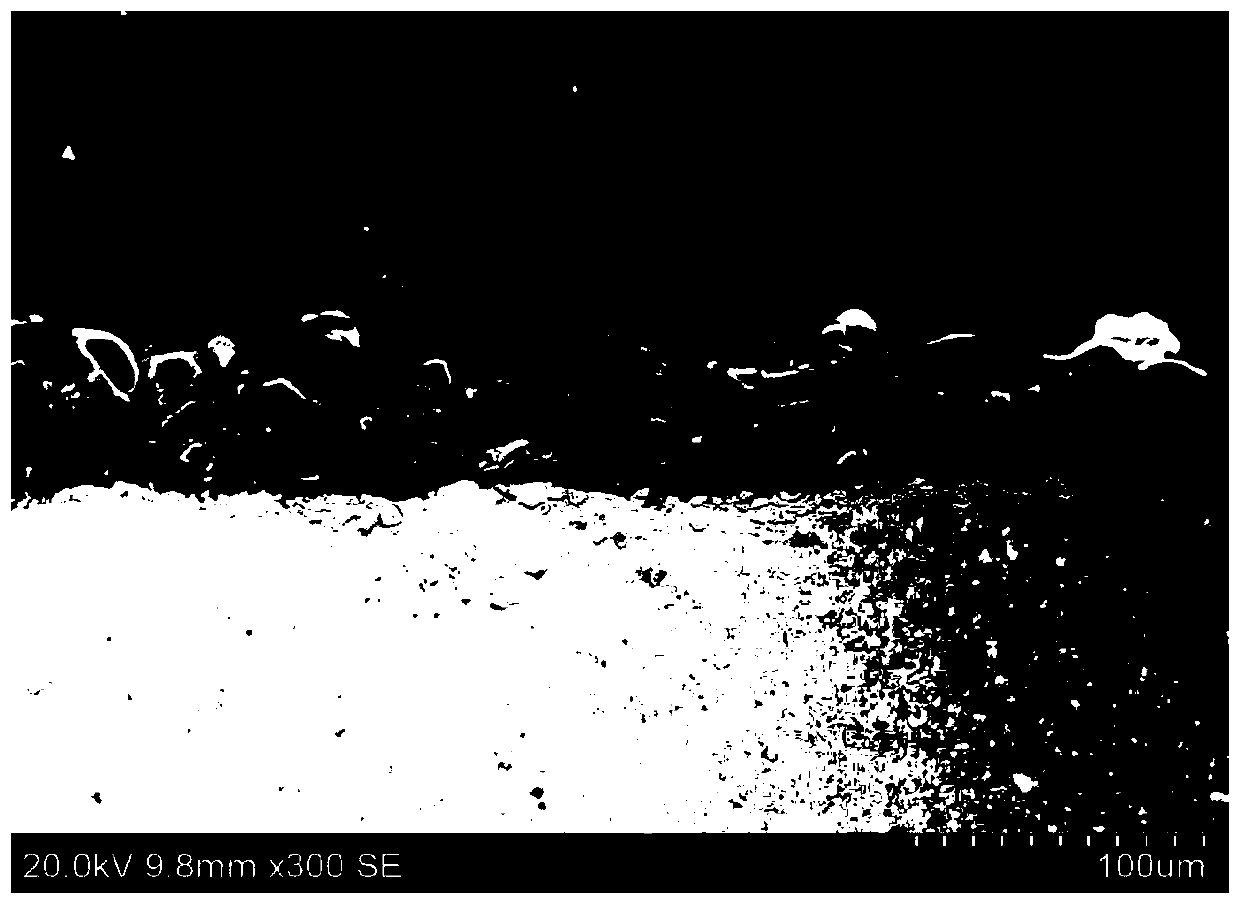

[0050] In this embodiment, cold sprayed aluminum-based composite anti-corrosion coatings are prepared, that is, from the surface of the NdFeB magnet to the outside, the cold sprayed aluminum coating, the aluminum oxide passivation layer obtained by surface passivation treatment, and the sealing ceramic paint layer are sequentially included.

[0051] In this embodiment, the preparation method of cold-sprayed aluminum-based composite corrosion-resistant coating specifically includes the following steps:

[0052] (1) Surface treatment of NdFeB substrate; select N42 NdFeB substrate with a thickness of 5mm, and use acid corrosion method to roughen its surface, which specifically includes the following steps: first degreasing the surface, and then Ultrasonic cleaning in water and ethanol for 5 minutes; then soaking in 2.5% nitric acid solution for 1 min for nitric acid acid corrosion, and then soaking in 2% citric acid solution for 2 min for citric acid activation; finally Ultrasoni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com