Preparation method of vanadium pentoxide

A technology of vanadium pentoxide and vanadium slag, which is applied in the field of metallurgical vanadium extraction, can solve the problem of low impurity content in products, and achieve the effect of less chemical consumption, low content of impurity elements, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

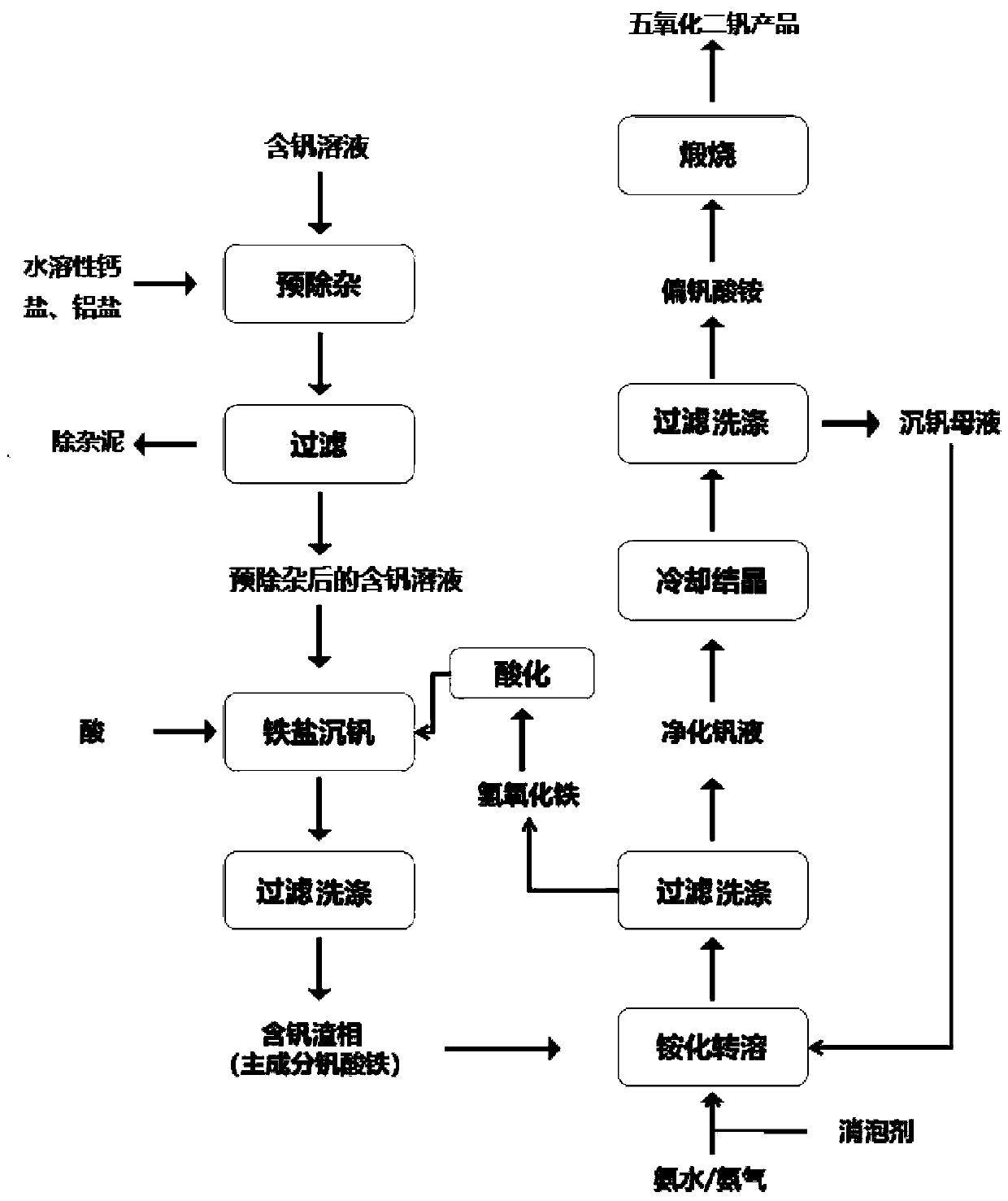

[0065] The specific embodiment part of the present invention provides a kind of preparation method of vanadium pentoxide, described method comprises the following steps:

[0066] (1) Precipitating vanadium under acidic conditions after mixing the vanadium-containing solution with iron salt to obtain a vanadium-containing slag phase;

[0067] (2) Mix the vanadium-containing slag phase obtained in step (1) with an ammonizing agent after forming a dispersion liquid, and transfer to dissolve under heating conditions to obtain a purified vanadium liquid;

[0068] (3) cooling and crystallizing the purified vanadium liquid obtained in step (2) and then calcining to obtain a vanadium pentoxide product.

Embodiment 1

[0071] This embodiment provides a method for preparing vanadium pentoxide, using the vanadium-containing solution obtained by extracting vanadium from vanadium slag as the raw material solution, wherein the vanadium content is 24.8g / L, and the content of other elements is respectively iron 92ppm, chromium 351ppm, manganese 25ppm, phosphorus 264ppm, silicon 650ppm calcium 59ppm, magnesium 33ppm, aluminum 21ppm, sodium 19.8g / L, potassium 1.5g / L;

[0072] The process flow diagram of the method is as figure 1 shown, including the following steps:

[0073] (1) Add calcium chloride and aluminum chloride to the vanadium-containing solution, the mol ratio of the calcium in the calcium chloride to the phosphorus in the vanadium-containing solution is 1.1:1, the aluminum in the aluminum chloride and the silicon in the vanadium-containing solution The molar ratio is 1.2:1, stirred and reacted at 70°C for 30 minutes, and filtered to obtain the vanadium-containing solution and the impurit...

Embodiment 2

[0079] The present embodiment provides a kind of preparation method of vanadium pentoxide, the composition of vanadium-containing solution used is identical with embodiment 1; Described method comprises the following steps:

[0080] (1) Add calcium nitrate and aluminum nitrate to the vanadium-containing solution, the molar ratio of calcium in calcium nitrate to phosphorus in the vanadium-containing solution is 1.2:1, and the molar ratio of aluminum in aluminum nitrate to silicon in the vanadium-containing solution is 1.4 : 1, stirred and reacted for 20min at 85°C, filtered to obtain the vanadium-containing solution and the impurity-removed mud after pre-removal;

[0081] (2) Add ferric nitrate to the vanadium-containing solution after the pre-removal of impurities in step (1), the add-on of ferric nitrate is 1.3:1 by the mol ratio of iron element and vanadium in the vanadium-containing solution, adding nitric acid to adjust the pH value is 4. Precipitate vanadium at 60°C under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com