Iron-doped porous indium oxide gas sensitive material and preparation method and application thereof

A gas-sensing material and iron-doped technology, which are applied in the field of iron-doped porous indium oxide gas-sensing materials and their preparation, can solve the problems of high working temperature, poor selectivity, low sensitivity and the like, and achieve high sensitivity, uniform size, and good effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

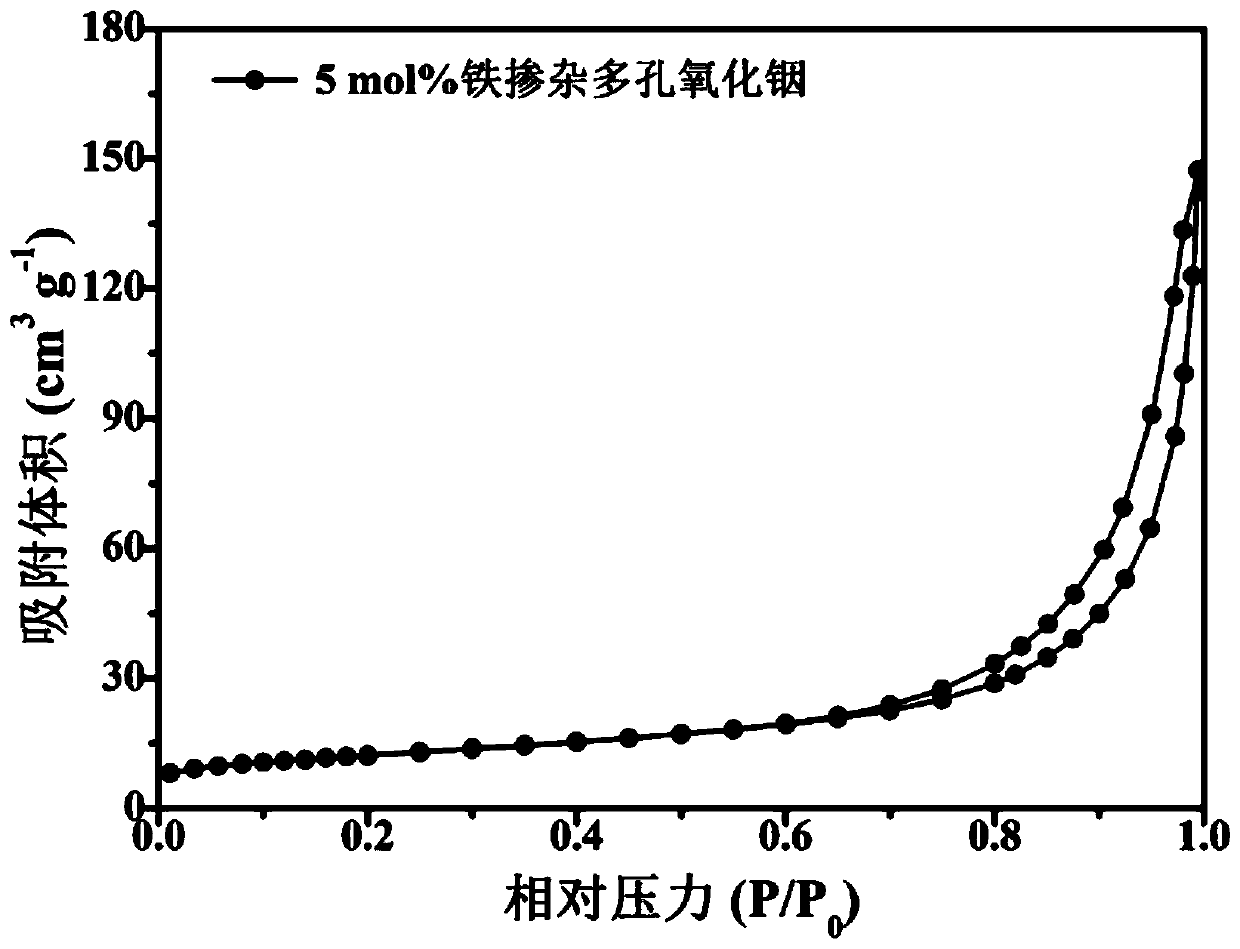

[0058] first embodiment , a preparation method of iron-doped porous indium oxide gas sensing material, comprising the following steps:

[0059] (1) 0.39g of the base material In (NO 3 ) 3 ·4.5H 2 O, 0.0175g doped phase raw material Fe(C 15 H 21 O 6 ), 0.18g organic ligand H 2 BDC was added to 75ml of organic solvent N,N-dimethylacetamide and stirred until dissolved;

[0060] (2) The clear liquid stirred in step (1) is placed in an oil bath at 100° C. for 10 min to react, so that the raw materials undergo a coordination polymerization reaction to obtain a coordination polymer of indium iron, and then the polymer is centrifuged to separate out , washed with methanol for 5 times, and dried in an oven at 80 °C.

[0061] (3) The dried coordination polymer of indium iron is calcined in a muffle furnace at 500° C. for 2 hours to obtain a powdery iron-doped porous indium oxide gas sensing material.

no. 2 example

[0062] Second Embodiment , a preparation method of iron-doped porous indium oxide gas sensing material, the same as Example 1, the difference is: in step (1), the molar ratio of the doping phase to the matrix material is 3mol%, 10mol%, and 20mol%.

no. 3 example

[0063] Third Embodiment , a preparation method of iron-doped porous indium oxide gas sensing material, comprising the following steps:

[0064] (1) 0.39g base material indium chloride, 0.0175g doped phase raw material Fe(NO 3 ) 3 , 0.09g organic ligand H 2 BDC was added to 75ml of organic solvent N,N-dimethylacetamide and stirred until dissolved;

[0065] (2) The clear liquid stirred in step (1) is placed in an oil bath at 80° C. for 20 min to react, so that the raw material undergoes a coordination polymerization reaction to obtain a coordination polymer of indium iron, and then the polymer is centrifuged to separate out , washed with methanol for 5 times, and dried in an oven at 80 °C.

[0066] (3) calcining the dried indium-iron coordination polymer at 450° C. for 2.5 hours in a muffle furnace to obtain a powdered iron-doped porous indium oxide gas sensing material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com