System and method applicable to softening and reuse treatment of reclaimed water in waste incineration power plant

A waste incineration and treatment system technology, applied in the field of wastewater treatment, can solve the problems of poor removal effect of calcium and magnesium hardness and alkalinity, few types of chemicals, single flocculation sedimentation + filtration process, etc., to achieve good water quality and automation The effect of high degree and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

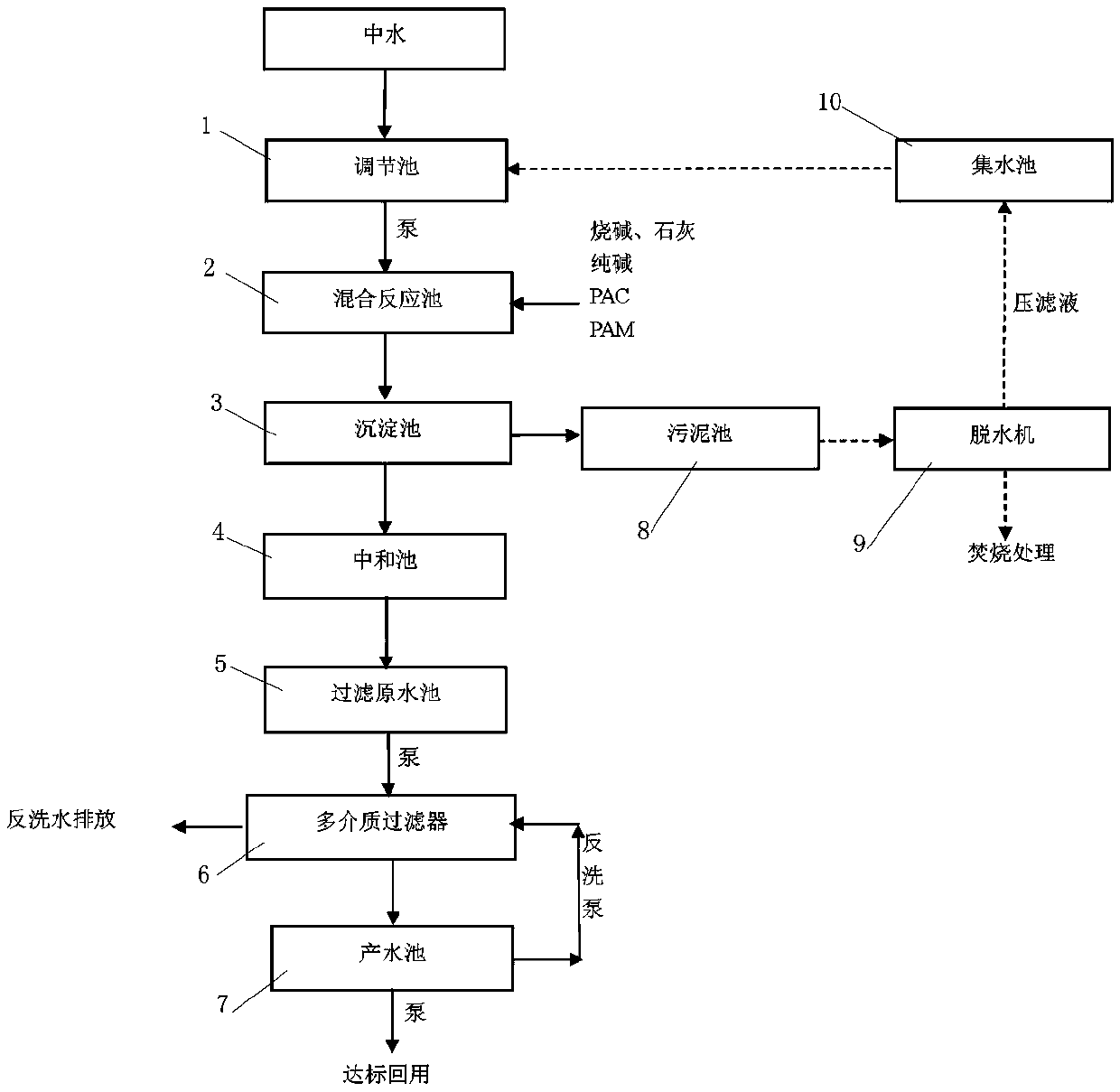

[0014] like figure 1 Shown is the flowchart of the present invention. The present invention is a reclaimed water softening and reuse treatment system suitable for waste incineration power plants, which comprises a regulating tank 1, a mixing reaction tank 2, a sedimentation tank 3, a neutralization tank 4, a filter raw water tank 5, The multi-media filter 6 and the water production tank 7, and the water output from the water production tank 7 is reused; among them, the mixing reaction tank 2 is connected with a dosing device, and the sedimentation tank 3 is connected to the sludge tank 8; the water production tank 7 is also connected to the multi-media through a backwash pump The filter 6, the multi-media filter 6 has a backwash water discharge end to discharge the backwash water.

[0015] Moreover, the sludge pool 8 is connected to the dewatering machine 9 , and the dewatering machine 9 is connected to the sump 10 , and the sump 10 is connected to the regulating tank 1 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com