A method for preparing furoic acid by oxidation of furfural on a microchannel reactor

A microchannel reactor, furfural technology, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, organic chemistry, etc., can solve the problems of low mixing efficiency of materials, difficult control of thermal energy, low yield, etc. The effect of improving yield, reducing side reactions, and large heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The specific preparation process of the capillary in the microchannel reactor is as follows:

[0025] (1) Al 2 o 3 Heat the superfine powder at 300°C for 2 hours, add 1,3-propanediol to make a suspension, ultrasonicate the suspension for 1 hour to make the dispersion uniform, and remove the dissolved air, and inject the suspension into the quartz capillary;

[0026] (2) Turn on nitrogen, flow through the whole capillary with low-speed nitrogen, pass the liquid plug formed by the suspension in the capillary through the whole capillary, and then pass low-speed nitrogen for 4 hours to remove the suspension, and then heat to 200°C to remove the solvent;

[0027] (3) Repeat the above steps 3 times;

[0028] (4) Dissolve 5.0 g of copper nitrate in 8-10 mL of distilled water, stir to dissolve, and immerse the capillary loaded with alumina particles in the copper nitrate solution for 10 h;

[0029] (5) Take out the capillary, dry it in an oven at 110 °C for 10 h, and finally...

Embodiment 2

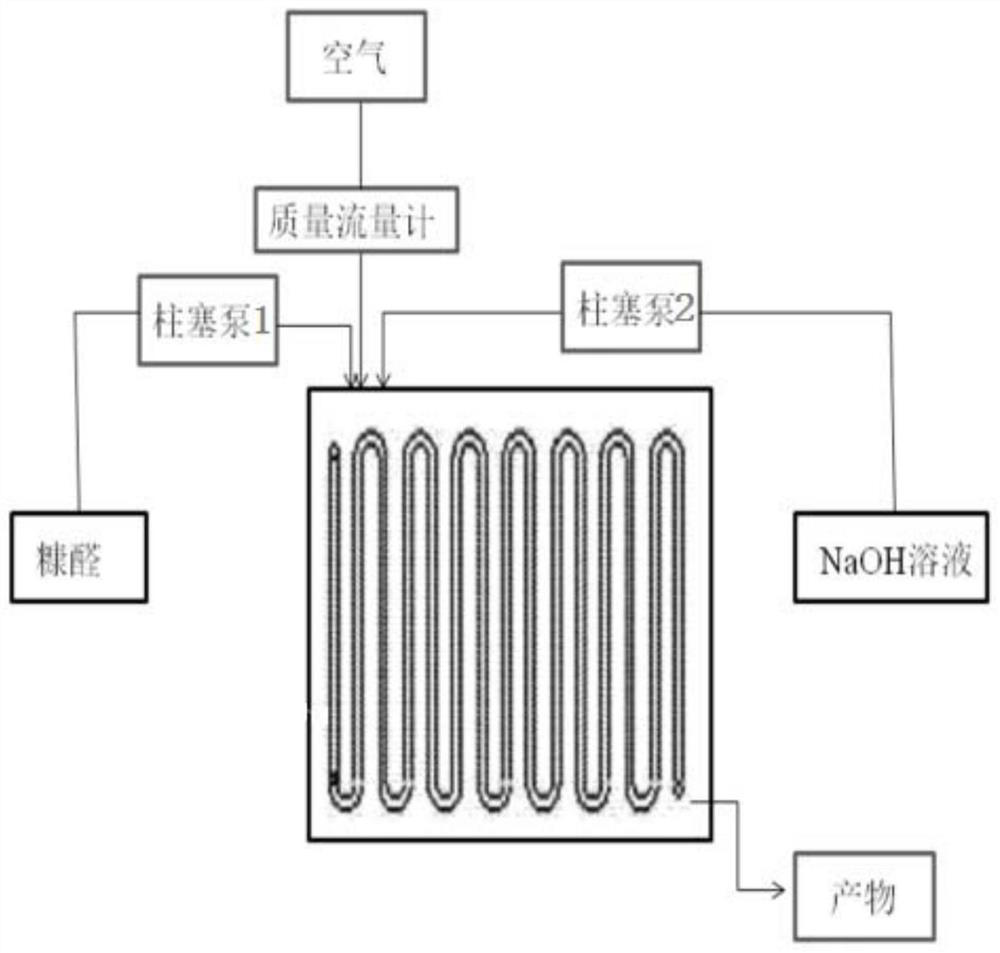

[0031] (1) 48.3 g furfural and an equimolar amount of NaOH solution, the concentration of NaOH solution is 1.0 mol / L, are transported into the microchannel reactor by a plunger pump, and the air is fed at a space velocity of 1000 h -1 Pass into the microchannel reactor, control the reaction temperature to 40°C, and the reaction residence time to 10min, and obtain the reaction liquid from the outlet of the reactor.

[0032] The above-mentioned microchannel reactor is composed of 30 capillary tubes with an inner diameter of 0.32 mm and a length of 10 cm obtained in Example 1, which are divided into an inlet section and an outlet section, and are fixed by connecting screws. The two ends of the capillary are respectively packaged in the inlet section and the outlet section by the packaging board, and the two packaging boards are respectively provided with at least one heating hole and a measurement and control thermocouple socket.

[0033] (2) Control the temperature of the reacti...

Embodiment 3

[0036] (1) 38.3 g furfural and an equimolar amount of NaOH solution, the concentration of NaOH solution is 1.0 mol / L, are transported into the microchannel reactor by a plunger pump, and the air is fed at a space velocity of 3000 h -1 Pass it into a microchannel reactor, control the reaction temperature at 45°C, and the reaction residence time for 5 min, and obtain the reaction liquid from the outlet of the reactor.

[0037] The above-mentioned microchannel reactor is composed of 30 capillary tubes with an inner diameter of 0.32 mm and a length of 10 cm obtained in Example 1, which are divided into an inlet section and an outlet section, and are fixed by connecting screws. The two ends of the capillary are respectively packaged in the inlet section and the outlet section by the packaging board, and the two packaging boards are respectively provided with at least one heating hole and a measurement and control thermocouple socket.

[0038] (2) Control the temperature of the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com