Slurry polymerization method for preparing bimodal distribution star-branched butyl rubber by using imino-terminated functionalized macromolecular branching agent

A technology with terminal imino function and bimodal distribution, applied in the field of butyl rubber preparation, can solve the problems of unsuitability for industrial application and high gel content, and achieve fast stress relaxation, low solution viscosity, and good carbon black compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

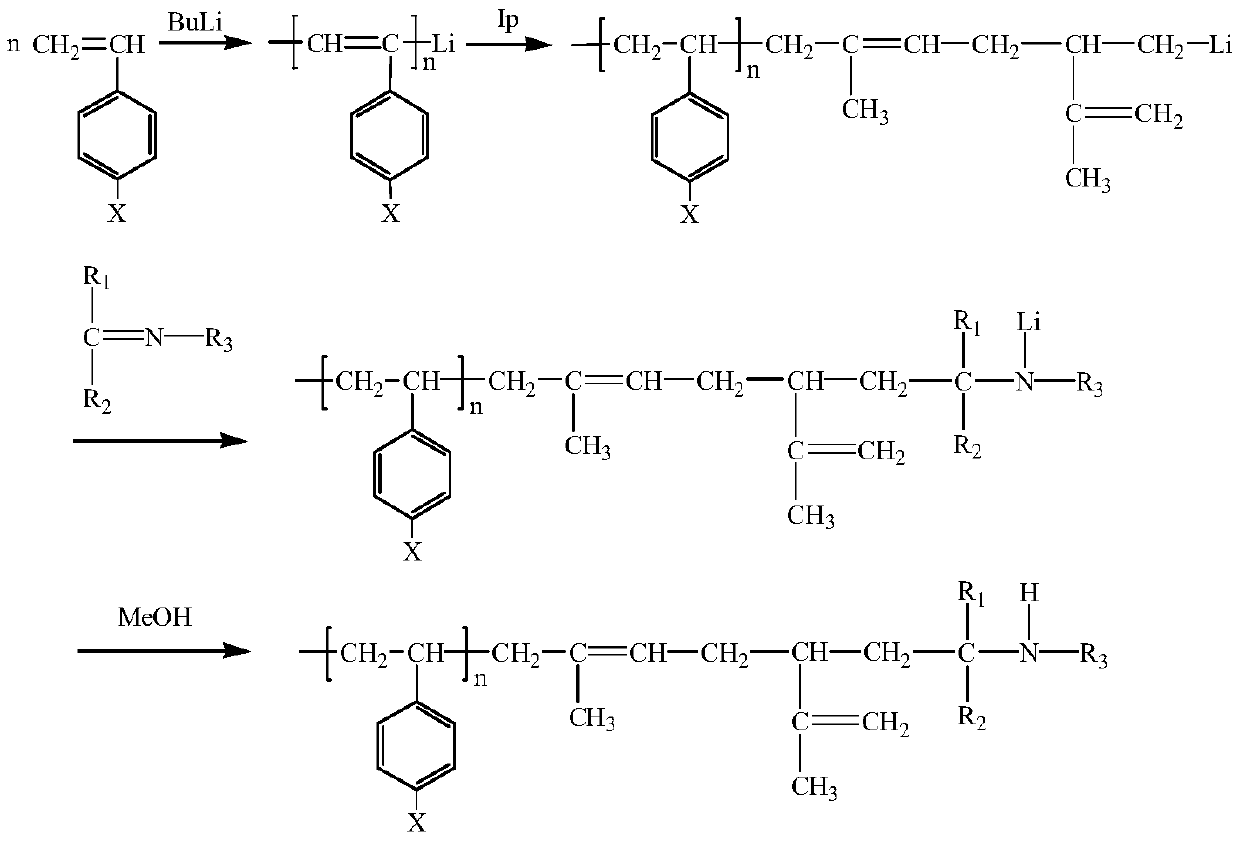

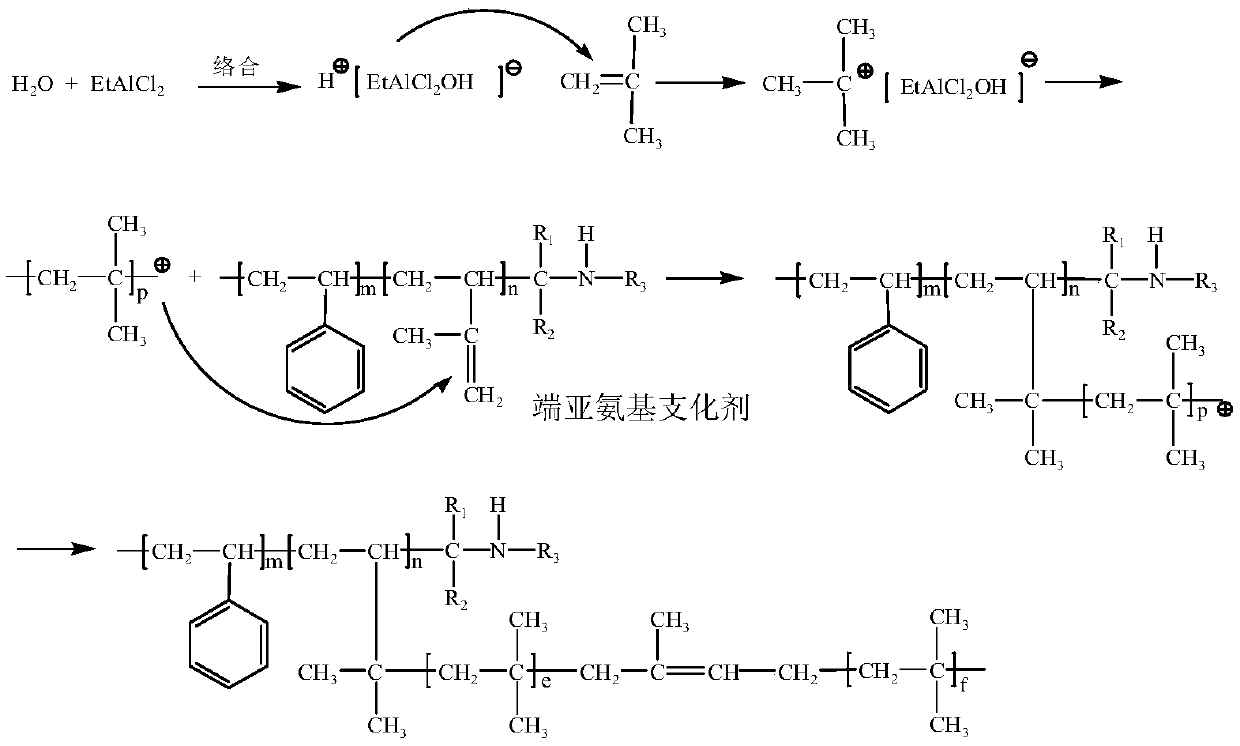

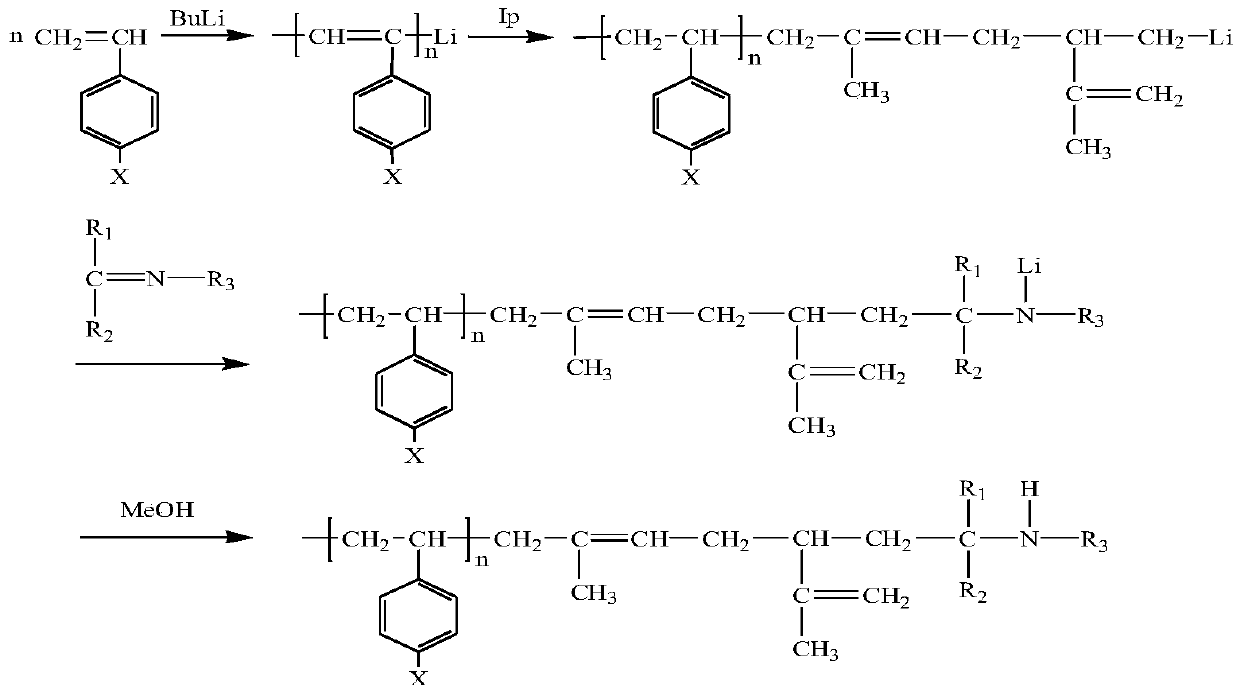

Image

Examples

Embodiment 1

[0044] (1) Under anhydrous and oxygen-free conditions, add 250 mL of cyclohexane, 16 mL of styrene, 1 mL of tetramethylethylenediamine (TMEDA) and 0.7 mL of n-butyllithium (0.9 M hexane solution) into the polymerization bottle, Shake well and seal, react at 50°C for 5 hours, then add 12mL of isoprene, react at 50°C for 6 hours, add 2mL of p-N,N-dimethylaminobenzoic acid aniline (0.1M, cyclohexyl alkane solution), react at 60°C for 30min, add cyclohexane and methanol to repeatedly flocculate and dissolve the product, wash off unreacted p-N,N-dimethylaminobenzoic acid aniline, and dry in a vacuum oven at 30°C Spare, number SI-1.

[0045] (2) Dissolve the branching agent sample of 0.2% of the total monomer weight in 40mL of dichloromethane, add it to a 4L polymerization kettle with a total volume, add 1296mL of methyl chloride, 536mL of isobutylene, 29mL of isoprene, and the rotation speed of the stirring paddle is 190r / min, the temperature drops below -85°C, take 2.65mL of dic...

Embodiment 2

[0049] (1) Under anhydrous and oxygen-free conditions, add 250 mL of cyclohexane, 16 mL of styrene, 1 mL of tetramethylethylenediamine (TMEDA) and 0.7 mL of n-butyllithium (0.9 M hexane solution) into the polymerization bottle, Shake well and seal, react at 50°C for 5 hours, then add 12mL of isoprene, react at 50°C for 6 hours, add 2mL of p-N,N-dimethylaminobenzoic acid aniline (0.1M, cyclohexyl alkane solution), react at 60°C for 30min, add cyclohexane and methanol to repeatedly flocculate and dissolve the product, wash off unreacted p-N,N-dimethylaminobenzoic acid aniline, and dry in a vacuum oven at 30°C Spare, number SI-1.

[0050] (2) Dissolve the 0.5% branching agent sample of the total monomer weight in 40mL of dichloromethane, add it to a total volume of 4L polymerization kettle, add 1296mL of methyl chloride, 536mL of isobutylene, 29mL of isoprene, and the stirring speed of the impeller is 190r / min, the temperature was lowered to below -85°C, 2.65mL of saturated dic...

Embodiment 3

[0052] (1) Under anhydrous and oxygen-free conditions, add 250 mL of cyclohexane, 16 mL of styrene, 1 mL of tetramethylethylenediamine (TMEDA) and 0.7 mL of n-butyllithium (0.9 M hexane solution) into the polymerization bottle, Shake well and seal, react at 50°C for 5 hours, then add 12mL of isoprene, react at 50°C for 6 hours, add 2mL of p-N,N-dimethylaminobenzoic acid aniline (0.1M, cyclohexyl alkane solution), react at 60°C for 30min, add cyclohexane and methanol to repeatedly flocculate and dissolve the product, wash off unreacted p-N,N-dimethylaminobenzoic acid aniline, and dry in a vacuum oven at 30°C Spare, number SI-1.

[0053] (2) Dissolve the 1.0% branching agent sample of the total monomer weight in 40mL of dichloromethane, add it to a 4L polymerization kettle with a total volume, add 1296mL of methyl chloride, 536mL of isobutylene, 29mL of isoprene, and the stirring speed is 190r / min, the temperature was lowered to below -85°C, 2.65mL of saturated dichloromethane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com