Efficient and environment-friendly silicon carbide smelting furnace

A silicon carbide and smelting furnace technology, applied in the direction of silicon carbide, carbide, furnace, etc., can solve the problems of increasing silicon carbide smelting cost, general thermal insulation performance, heat loss, etc., to improve resource utilization, good thermal insulation effect, reduce The effect of wasting energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

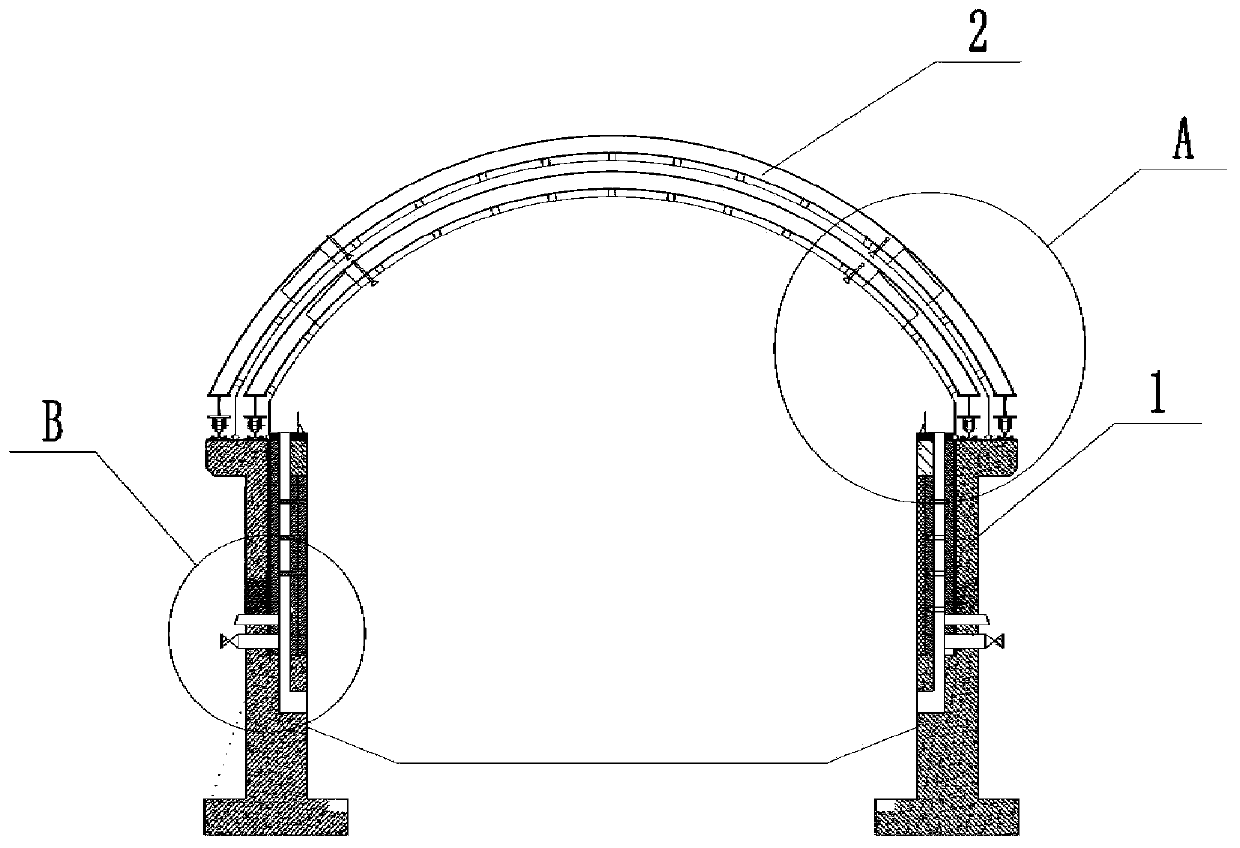

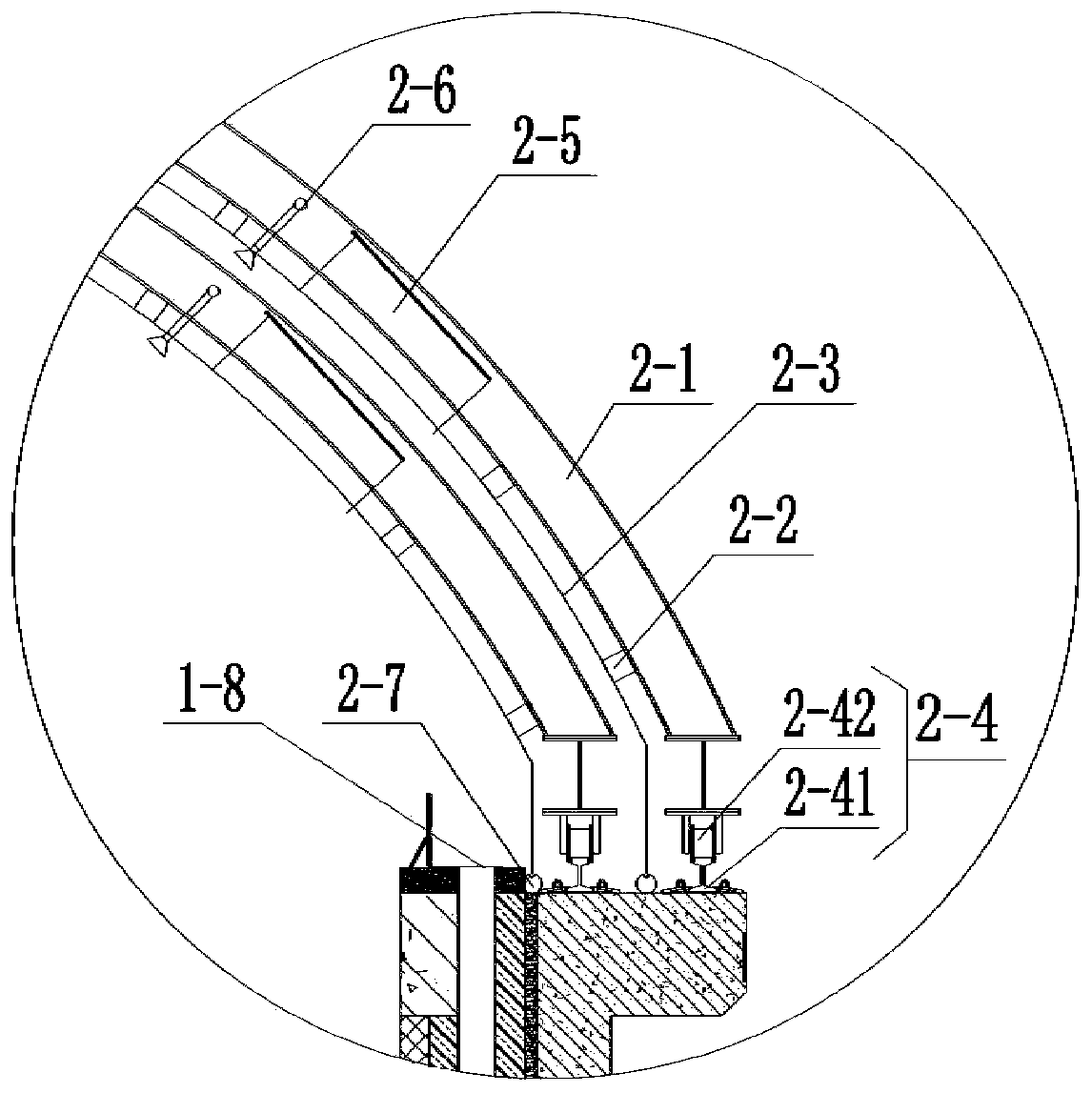

[0023] Such as Figure 1 to Figure 4 As shown, an efficient and environmentally friendly silicon carbide smelting furnace includes a furnace body and a dust collection hood.

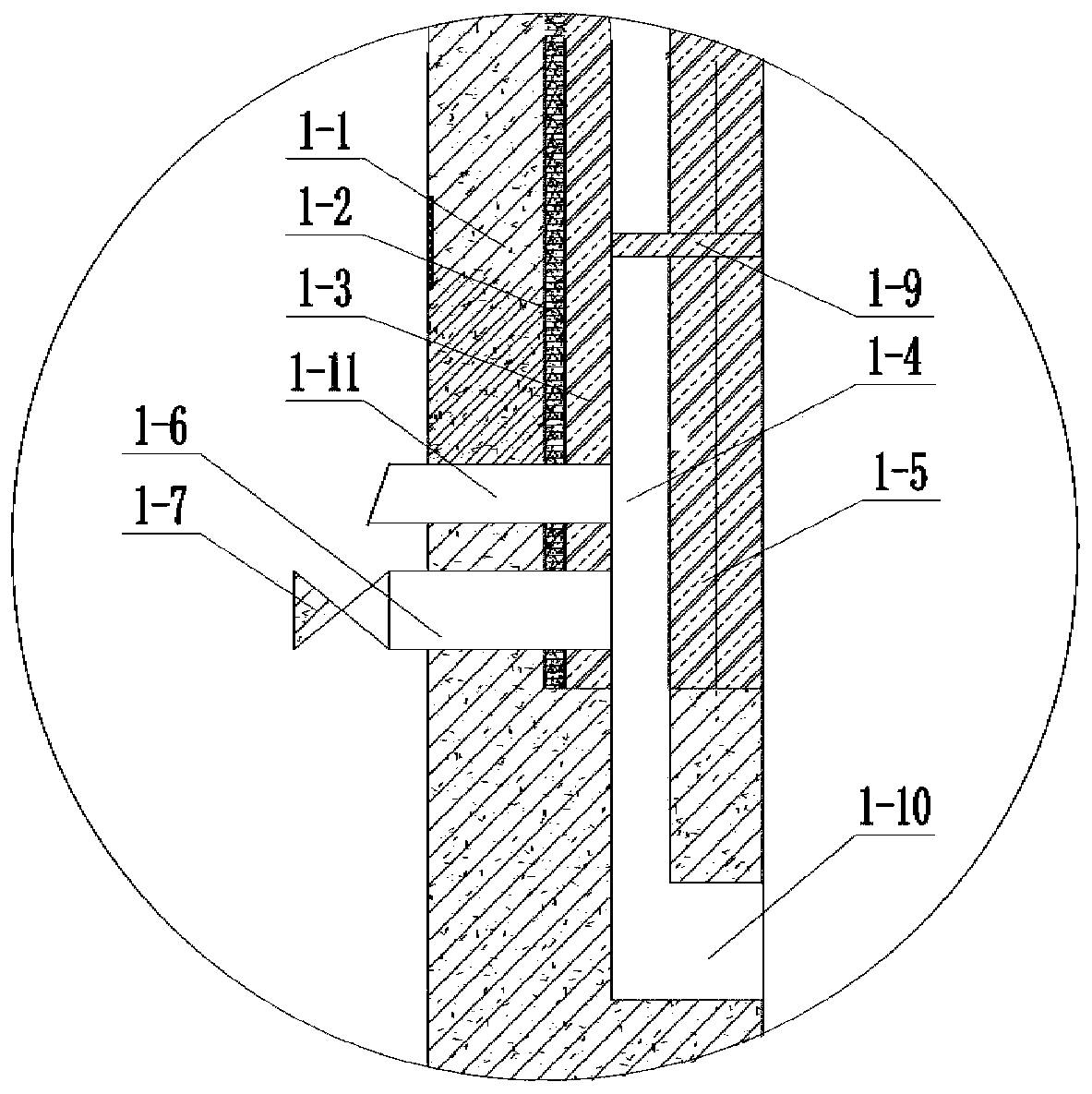

[0024] The furnace body includes a side wall 1, and the side wall 1 includes a reinforced concrete layer 1-1, a foam glass plate 1-2, a clay refractory brick layer 1-3, a combustion chamber interlayer 1-4, and composite refractory bricks arranged in sequence from outside to inside. Floor 1-5, air inlet pipe 1-6, self-locking manual butterfly valve 1-7, movable cover plate 1-8, inner support refractory brick 1-9, cavity 1-10, observation hole 1-11, electronic ignition gun and The pilasters; the reinforced concrete layer 1-1 has a thickness of 300mm, and the basic furnace wall structure is established through the reinforced concrete layer 1-1; the foam glass plate 1-2 is a silicon-calcium plate with a thickness of 50mm, and its function is heat insulation and protection Reinforced concrete layer 1; clay r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com