Method for preparing carbon-coated manganese oxygen compound electromagnetic wave absorbing material

A technology of manganese oxide compounds and absorbing materials, which is applied in chemical instruments and methods, nanotechnology for materials and surface science, manganese oxide/hydroxide, etc. , incomplete impedance matching, etc., to achieve the effect of large dielectric loss, good impedance matching, and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

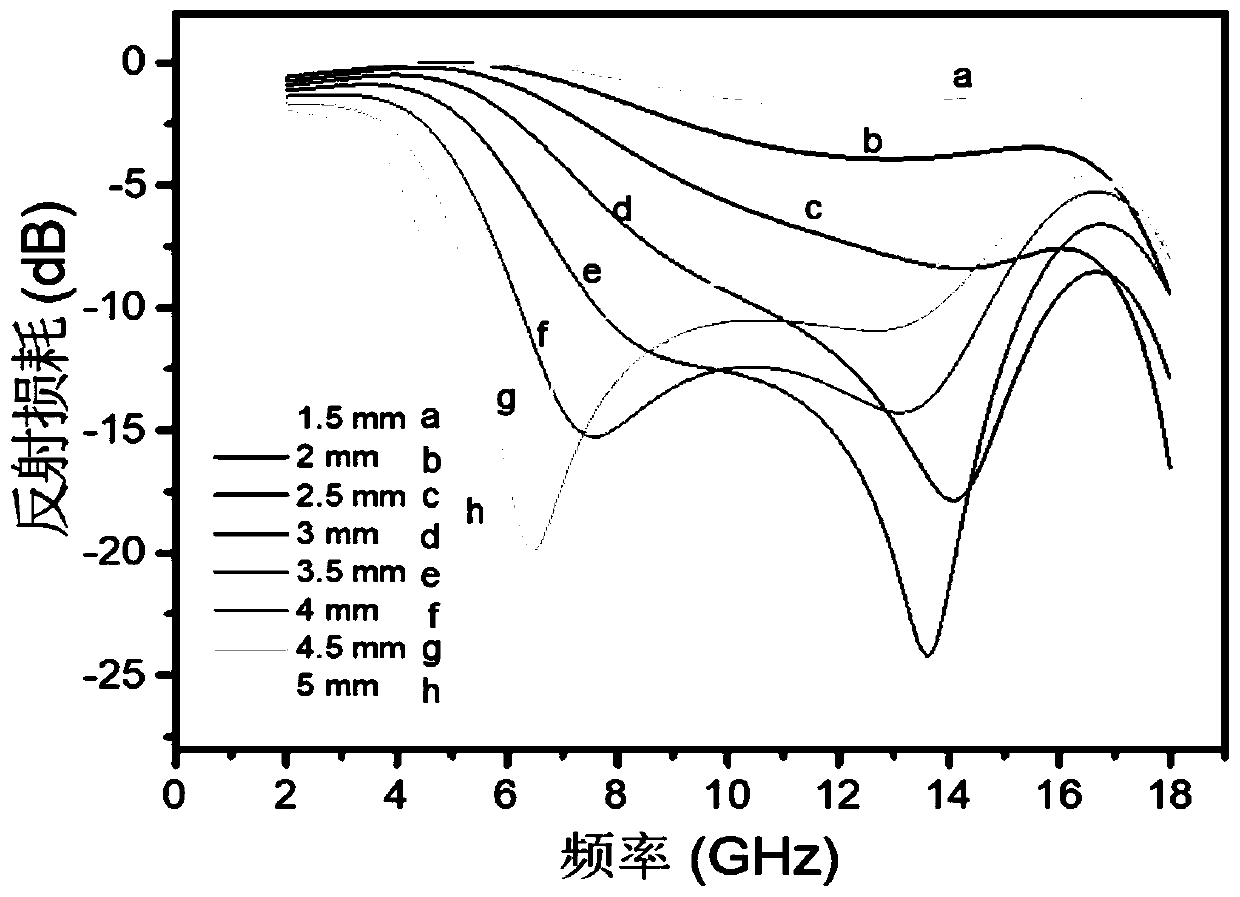

[0025] The carbon-coated manganese oxide wave-absorbing material prepared by the method of the present invention is compounded with paraffin, and the mass content of the carbon-coated manganese oxide wave-absorbing material prepared by the method of the present invention is 5%.

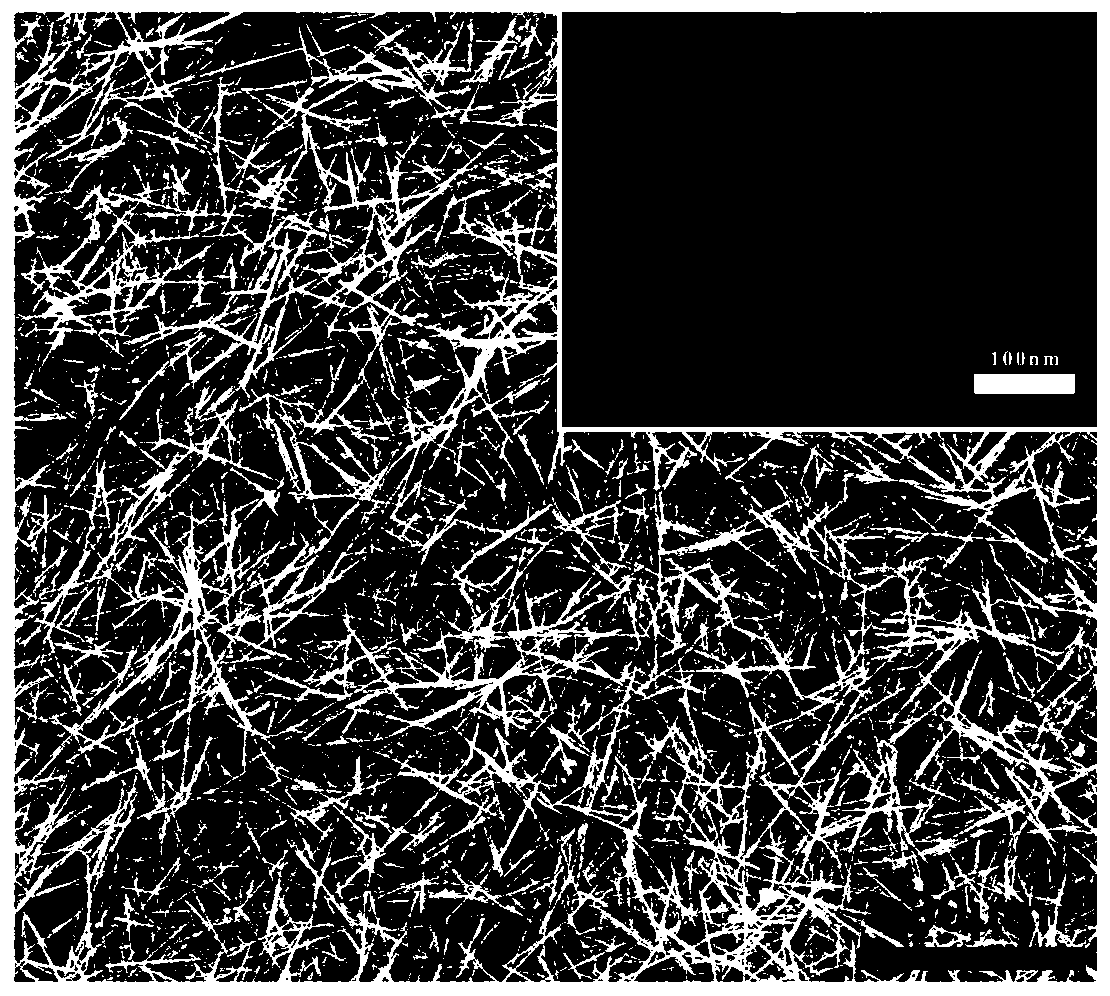

[0026] Step 1) Preparation of manganese oxyhydroxide nanowires: mix potassium permanganate and ethylene glycol in water at a mixing ratio of 0.2g: 1ml: 80ml, stir for 5h, then heat in a reactor at 130 degrees Celsius, and centrifuge for 10 hours to obtain product and dried; the microstructure of the obtained product manganese oxyhydroxide nanowires is as follows figure 1 shown.

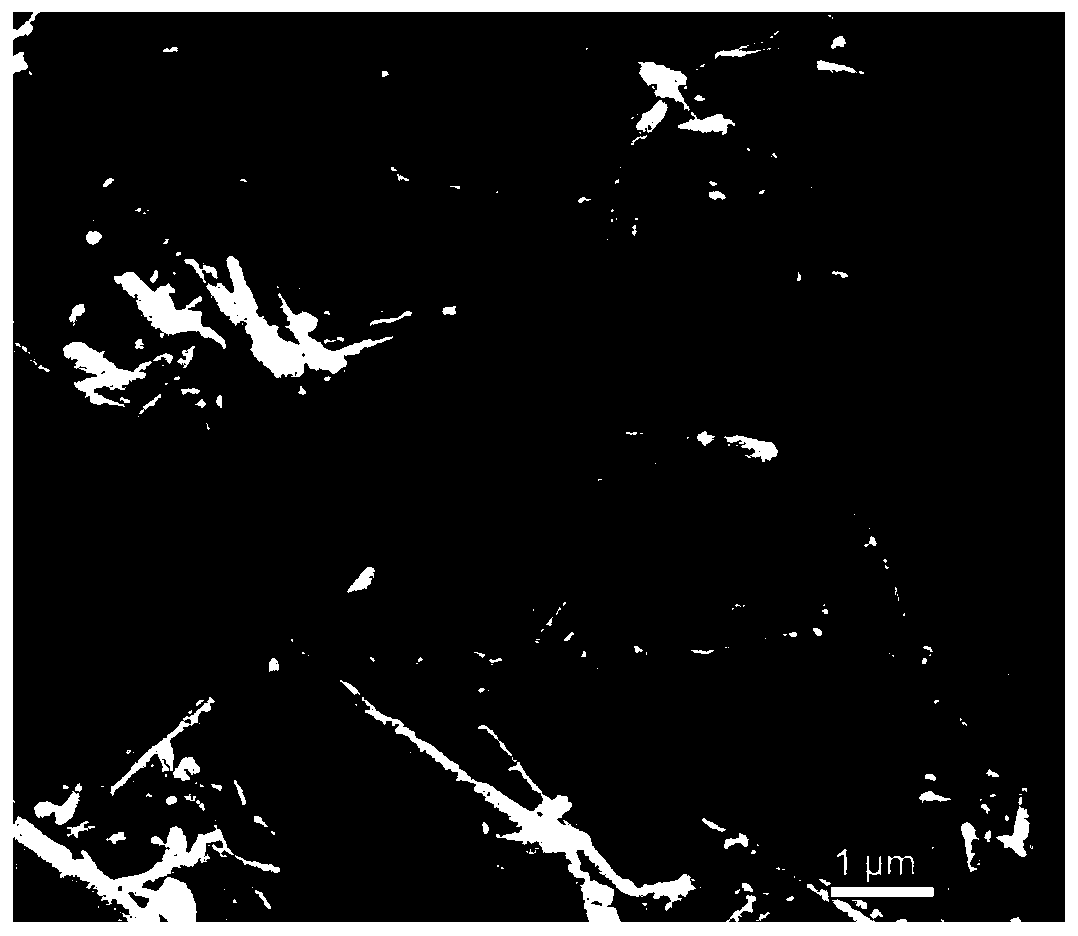

[0027] Step 2) Carry out carbon coating on manganese oxyhydroxide: mix manganese oxyhydroxide and dopamine hydrochloride in tris-hydrochloric acid buffer solution with the dried product obtained in step 1) according to the ratio of 80mg: 80mg: 200ml Stir for 4.5 hours, then centrifuge, and dry to obtain the product;

[0028...

Embodiment 2

[0031] The carbon-coated manganese oxide wave-absorbing material prepared by the method of the invention is compounded with paraffin wax, and the mass content of the carbon-coated manganese oxide wave-absorber material prepared by the method of the invention is 10%.

[0032] Step 1) Preparation of manganese oxyhydroxide nanowires: mix potassium permanganate and ethylene glycol in water at a mixing ratio of 0.2g: 1ml: 80ml, stir for 5h, then heat in a reactor at 130 degrees Celsius, and centrifuge for 10 hours to obtain product and dried; the microstructure of the obtained product manganese oxyhydroxide nanowires is as follows figure 1 shown.

[0033] Step 2) Carry out carbon coating on manganese oxyhydroxide: mix manganese oxyhydroxide and dopamine hydrochloride in tris-hydrochloric acid buffer solution with the dried product obtained in step 1) according to the ratio of 80mg: 80mg: 200ml Stir for 4.5 hours, then centrifuge, and dry to obtain the product;

[0034] Step 3) Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com