Metal lithium negative electrode with preset stable protective film and preparation method thereof

A protective film, metal lithium technology, applied in the field of metal lithium anode, can solve the problems of poor interface stability between metal lithium anode and electrolyte, and achieve the effects of improving cycle stability, improving cycle stability, and inhibiting lithium dendrite growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

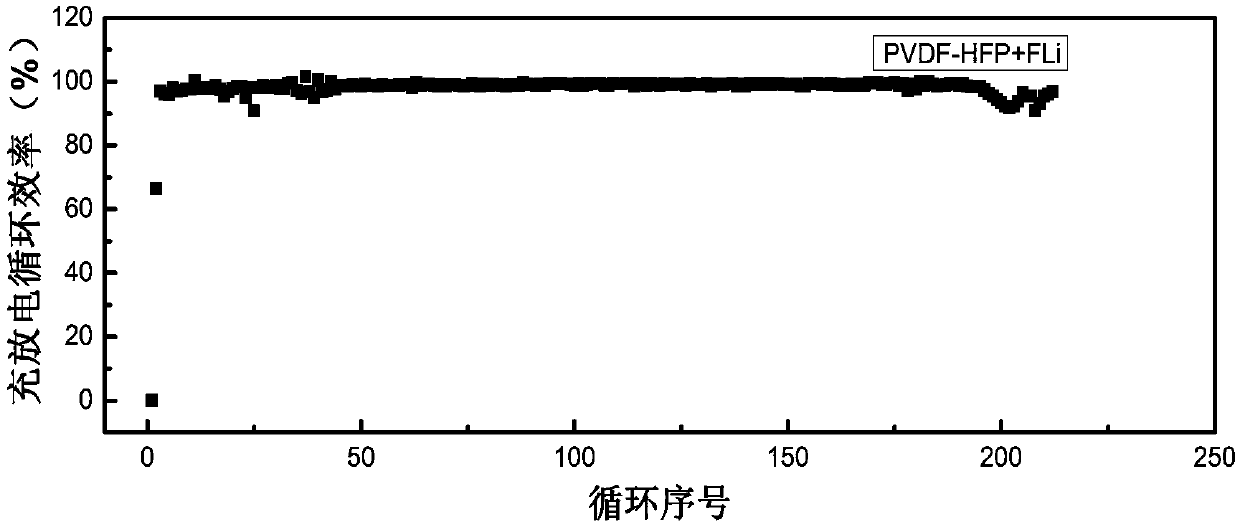

[0032] Specific Embodiments 1. In this embodiment, the preparation method of the metal lithium negative electrode with a preset stable protective film is carried out according to the following steps:

[0033] Step 1. Roughen the surface of the copper foil current collector: Soak the copper foil (or foamed copper) with 10% (mass) hydrochloric acid and oxygen for 30 minutes, then soak in distilled water, wash and dry with cold wind.

[0034] Step 2, the specific method of coating the elastic organic polymer protective film and curing to improve the strength is: (1) Lithium fluoride is mixed with PVDF-HFP in a ratio of 50% as a lithium salt, and added to acetone:DMAC with a ratio of 2:1 In the solvent, the ratio of the mixture to the solvent is 3:100 (mass ratio). Stir at room temperature for 12 hours, then ultrasonically for 2 hours to achieve uniformity and dispersion; (2) uniformly coat or dip-coat the dispersion in step 2 (1) on the surface of the roughened current collector ...

specific Embodiment approach 2

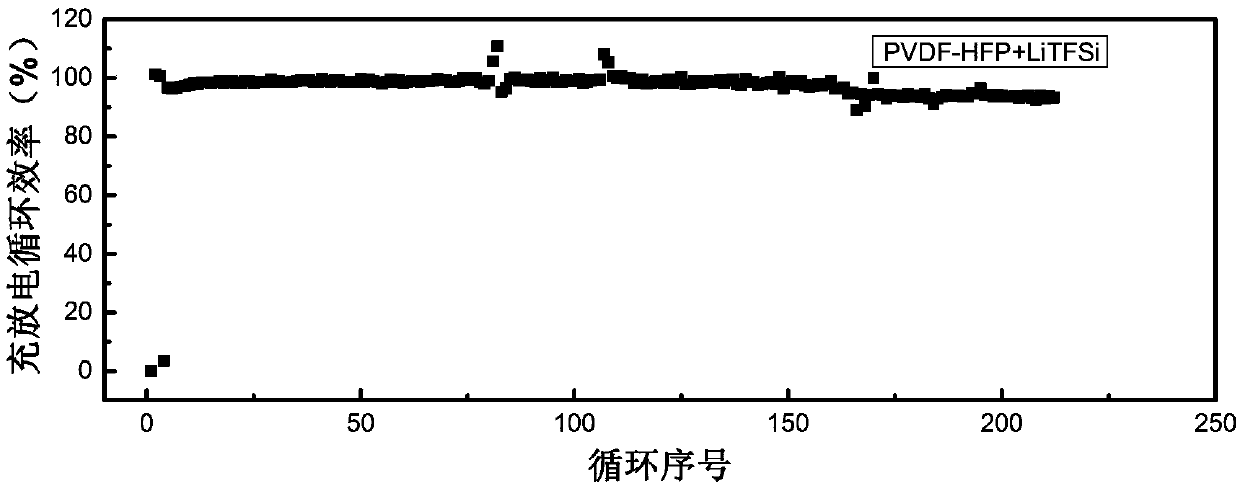

[0037] Embodiment 2. In this embodiment, the preparation method of the metal lithium negative electrode with a preset stable protective film is carried out according to the following steps:

[0038] Step 1. Roughen the surface of the copper foil current collector: Soak the copper foil or foamed copper with 10% hydrochloric acid and oxygen for 30 minutes, then soak in distilled water, wash and dry with cold wind.

[0039]Step 2, the specific method of coating the elastic organic polymer protective film and curing to improve the strength is as follows: (1) LiTFSi is mixed with PVDF-HFP at a ratio of 10% as an additive, and added to acetone: DMAC in a solvent of 2:1, The ratio of mixture to solvent is 3:100 (mass ratio). Stir at room temperature for 12 hours, then ultrasonically for 2 hours to achieve uniformity and dispersion; (2) uniformly coat or dip-coat the dispersion in step 2 (1) on the surface of the roughened current collector described in step 1; (3) The current collec...

specific Embodiment approach 3

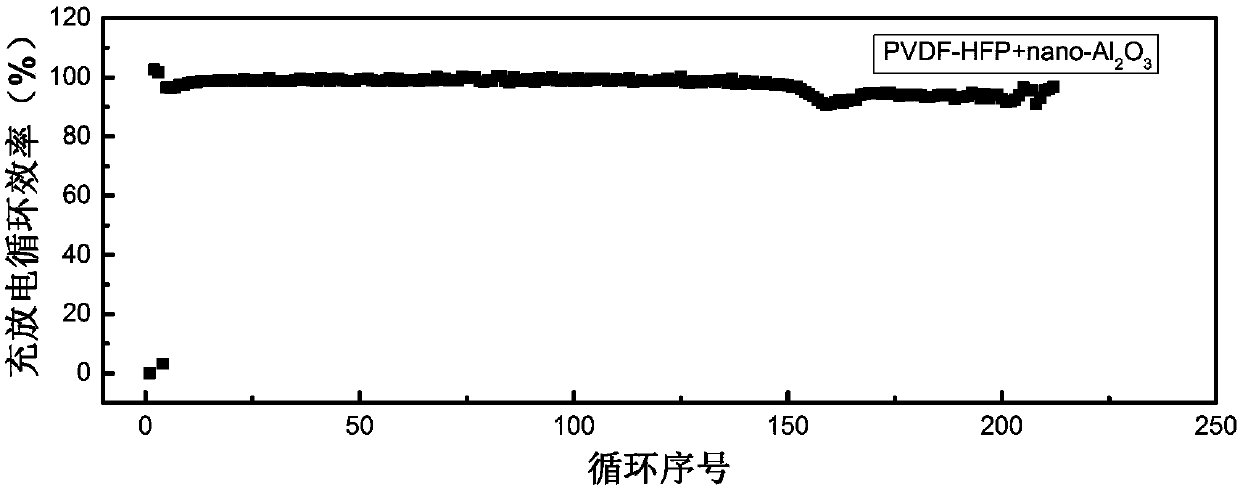

[0042] Specific Embodiment Three. In this embodiment, the preparation method of the metal lithium negative electrode with a preset stable protective film is carried out according to the following steps:

[0043] Step 1. Roughen the surface of the copper foil current collector: Soak the copper foil or foamed copper with 10% hydrochloric acid and oxygen for 30 minutes, then soak in distilled water, wash and dry with cold wind.

[0044] Step 2, the specific method of coating the elastic organic polymer protective film and curing to improve the strength is: (1) nano-alumina particles are mixed with PVDF-HFP in a ratio of 10% as an additive, and added to acetone: DMAC is 2:1 In the solvent, the ratio of the mixture to the solvent is 3:100 (mass ratio). Stir at room temperature for 12 hours, then ultrasonically for 2 hours to achieve uniformity and dispersion; (2) uniformly coat or dip-coat the dispersion in step 2 (1) on the surface of the roughened current collector described in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com